Inspecting cutterbar hardware, Warning – MacDon R85 Rotary Disc 16 Foot Self-Propelled Windrower Headers User Manual

Page 141

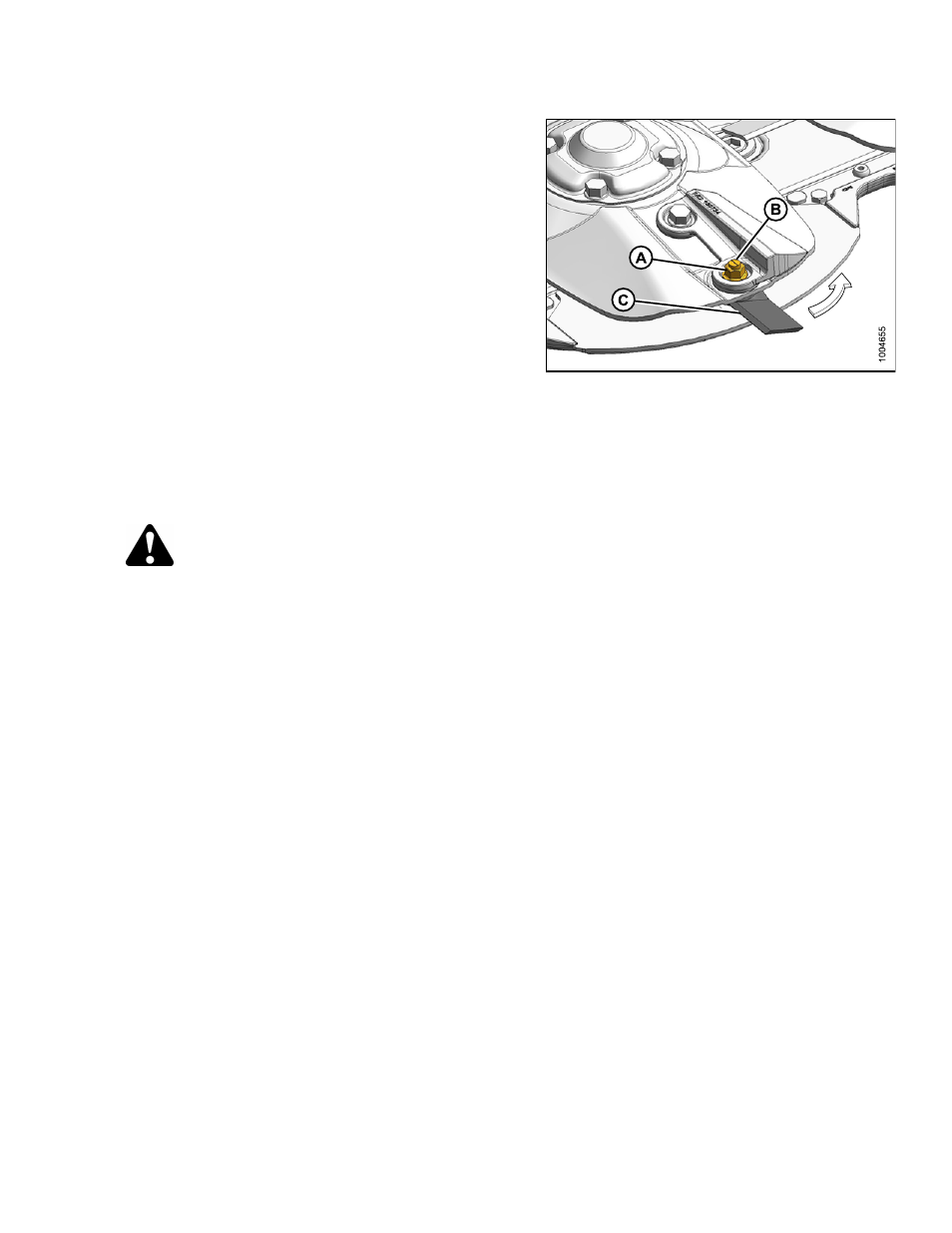

8. Remove nut (A).

9. Remove shoulder bolt (B) and blade (C).

10. Install new or reversed blade (C) with shoulder bolt (B)

onto disc.

NOTE: Ensure shoulder bolt is fully engaged into

blade before tightening nut.

NOTE: Ensure blade is installed correctly to suit

rotation of disc. Refer to Figures

•

7.29: Counterclockwise Disc Rotation

Direction, page 131

•

If you are unsure which direction the

spindle rotates,

see Section

Direction of Spindle Rotation, page 129

11. Install nut (A). Tighten nut to 100 ft·lbf (135 N·m).

12. Remove block of wood (if used).

WARNING

Ensure cutterbar is completely clear of foreign

objects.

These objects can be ejected with

considerable

force

when

the

machine

is

started and may result in serious injury or

machine damage.

13. Close cutterbar doors.

See Section

Figure 7.32

Inspecting Cutterbar Hardware

Check blade attachment hardware each time blades are replaced. See

Replacing the Cutter Blades, page 132

for

replacement procedure.

Check bolts for wear or damage and replace bolt if:

• Bolt has been removed and installed five times.

• Head is worn flush with bearing surface of blade.

• Diameter of bolt neck is worn out of specification.

• Bolt is cracked.

• Bolt is visibly distorted.

• Evidence of interference with adjacent parts.

Check nuts for wear or damage and replace nut if:

• Worn height is less than half total height.

• Nut is cracked.

• Nut has been removed and installed five times.

169457

133

Rev. F