2roll gap, 1checking roll gap, Roll gap – MacDon R85 Rotary Disc 16 Foot Self-Propelled Windrower Headers User Manual

Page 75: Checking roll gap, Danger, 2 roll gap

6.2 Roll Gap

Steel "n" bar rolls "condition" the crop by crimping and crushing the stem in several places. This allows moisture

release for quicker drying. The degree to which the crop is conditioned as it passes through the rolls is controlled

by roll gap.

The factory roll gap setting of 1 in. (25.4 mm), measured at the conditioner rolls corresponds to the roll gap setting

of 1-3/16 in. (30 mm), measured at the adjustment bolt.

Correct conditioning of alfalfa, clover, and other legumes is usually indicated when 90% of the stems show cracking,

but no more than 5% of the leaves are damaged. Set enough roll gap to achieve this result.

NOTE: If the conditioner rolls are set too tight (close together), can result in over conditioning the crop

material (excessive leaf damage), reduce machine capacity and use unnecessary horsepower.

Monitor your disc speed. When crop loads increase and disc speed falls by more than 50 rpm,

you should check conditioning action (on plant). Increased crop volume may result in increased

conditioning (leaf loss). Consider increasing roll gap slightly. With optional load sensor on M205,

a warning limit may be set to warn the Operator to slow down prior to a header stall or plug.

A larger gap may be desirable in thick stemmed cane-type crops; however, too large gap may cause feeding

problems.

Grass type crops may require less gap for proper feeding and conditioning.

6.2.1 Checking Roll Gap

DANGER

Stop engine and remove key from ignition before

leaving operator’s seat for any reason. A child or

even a pet could engage an idling machine.

1. Lower header fully.

2. Open the driveshield. See Section

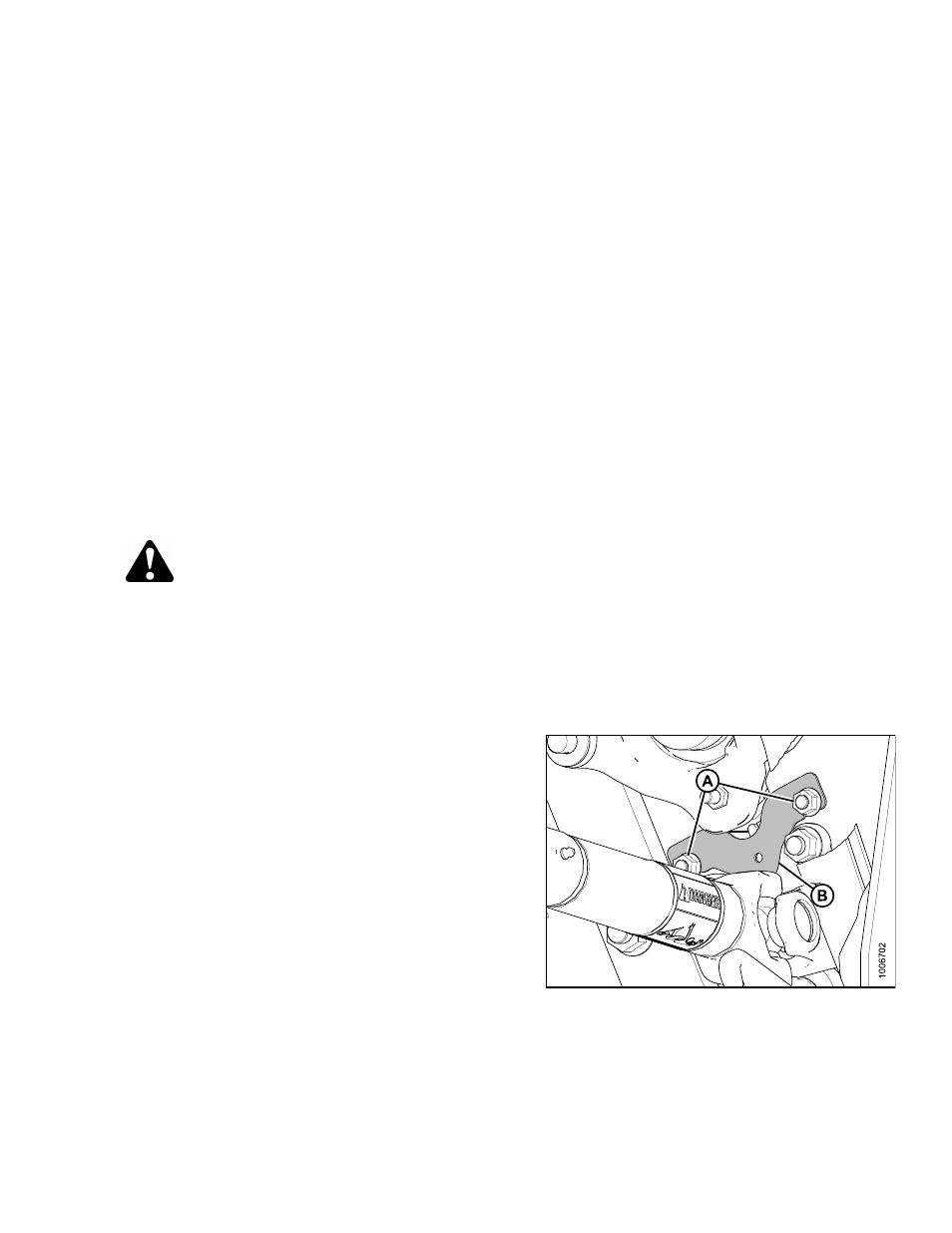

3. Remove bolts (A) that secure conditioner shield (B).

4. Remove the shield (B).

Figure 6.2

169457

67

Rev. F