6operating the header, 1header float, Operating the header – MacDon R85 Rotary Disc 16 Foot Self-Propelled Windrower Headers User Manual

Page 73: Header float, 6 operating the header, 1 header float

6 Operating the Header

Satisfactory operation of the header in all situations requires making proper adjustments to suit various crops

and conditions.

Correct operation reduces crop loss and increases productivity. As well, proper adjustments and timely maintenance

will increase the length of service you receive from the machine.

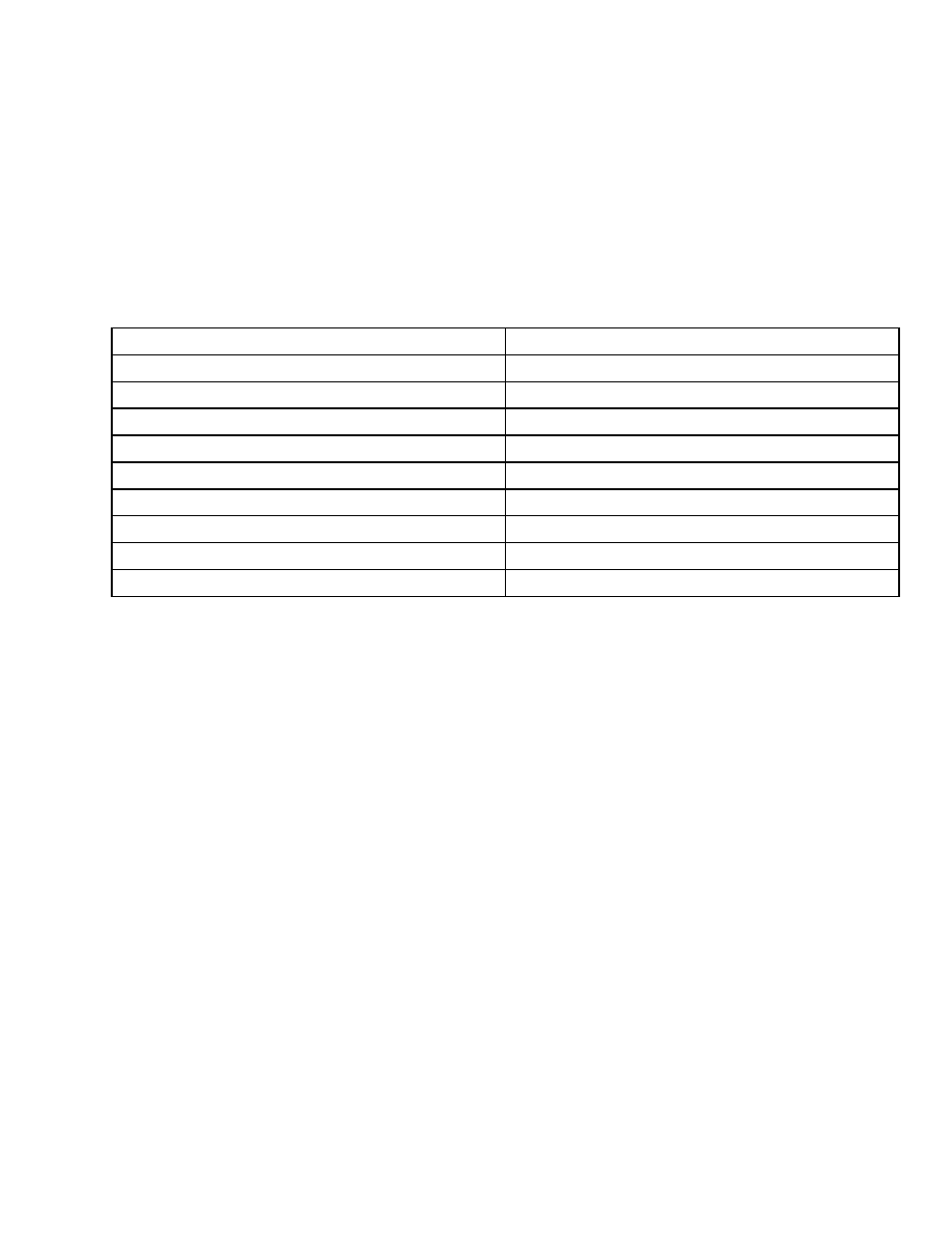

The variables listed below and detailed on the following pages will affect the performance of the header. You will

quickly become familiar with adjusting the machine to give you the desired results. Most of the adjustments have

been set at the factory, but if desired, the settings can be changed to suit crop conditions.

Variable

See Section

Header float

Roll gap

Roll tension

Roll timing

Forming shields

Header angle

Cutting height

Disc speed

Ground speed

6.1 Header Float

Header float springs are normally set so 95–105 lbf (426–471 N) is required to lift either end of the header just off

the ground.

In rough or stony conditions, it may be desirable to maintain a lighter setting to protect cutting components.

When float setting is light, it may be necessary to use a slower ground speed to avoid excessive bouncing resulting

in a ragged cut. Faster ground speeds may require additional ground pressure.

169457

65

Rev. F