MacDon R85 Rotary Disc 16 Foot Self-Propelled Windrower Headers User Manual

Page 168

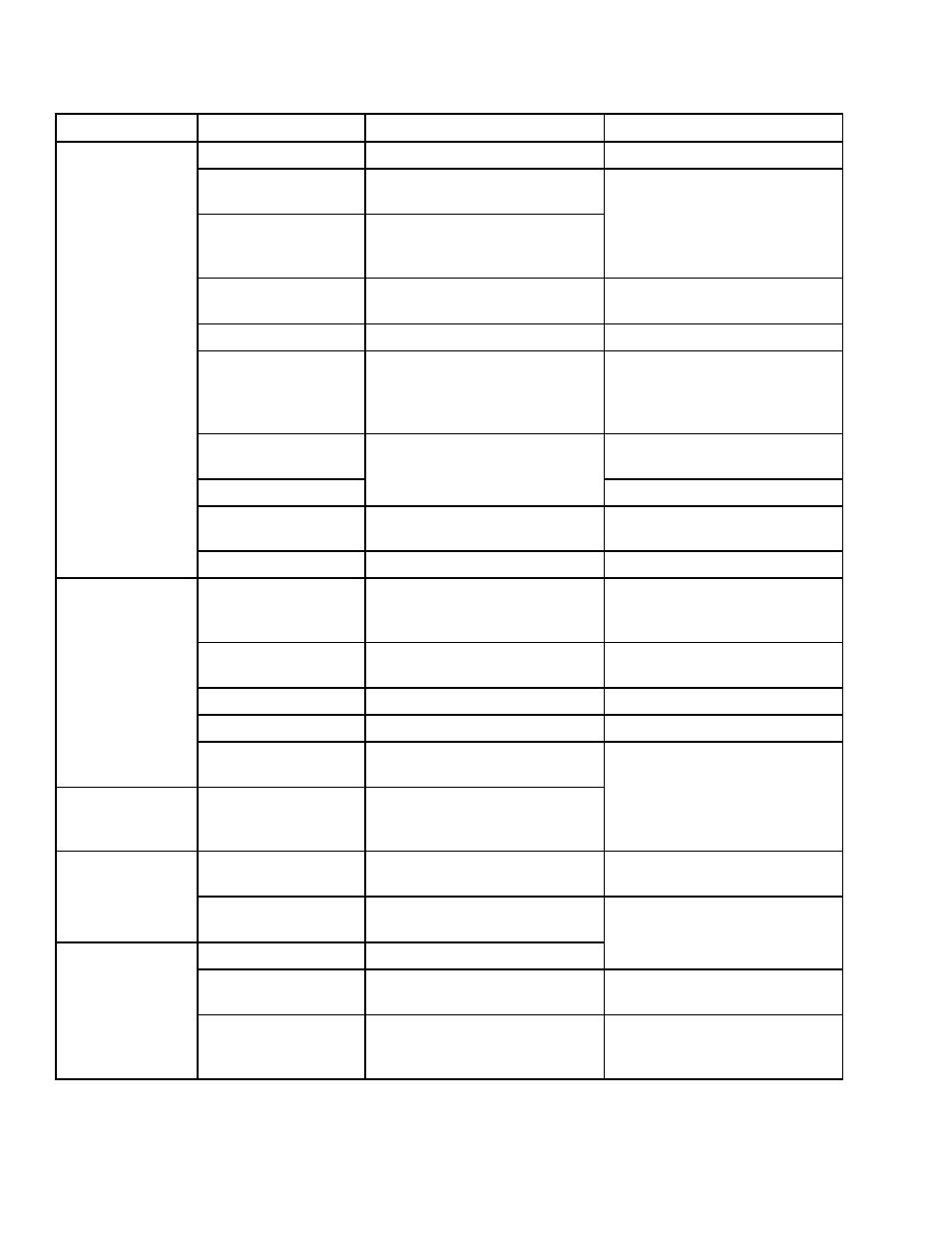

Symptom

Problem

Solution

Section

Ground speed too fast Reduce ground speed.

Roll gap too large for

proper feeding

Decrease roll gap.

Roll gap too small

in thick stemmed

cane-type crops

Increase roll gap.

Baffle set too low

Raise baffle.

6.5.3 Adjusting the Swath Baffle,

page 76

Roll speed too low

Increase disc speed.

Foreign object

between rolls

Disengage header and stop

engine. When all moving parts

are completely stopped, remove

foreign object.

–

Conditioner belt

slipping

7.7.2 Conditioner Drive Belt,

page 142

Auger belt slipping

Adjust belt tension.

7.7.5 Auger Drive Belt, page 150

Cutting height too low

Decrease header angle to raise

cutting height.

Conditioner rolls

plugging

Rolls improperly timed Adjust roll timing.

Rear deflector

bypassing or dragging

crop

Adjust rear deflector for proper

crop control.

6.5.2 Adjusting the Rear

Deflector (Fluffer Shield), page

76

Forming shields

improperly adjusted

Adjust forming shield.

Roll gap too large

Adjust roll gap.

Auger belts slipping

Replace belts.

7.7.5 Auger Drive Belt, page 150

Uneven formation

and bunching of

windrow

Conditioner rolls

running too slow

Maintain rated header speed.

Uneven windrow

formation in light

crop

Uneven feeding

Reduce header speed.

See windrower operator’s

manual

No cutting full header

width

Cut full header width.

–

Plugging behind

end cage

deflectors

Ground speed too

slow

Increase ground speed.

Ground speed too fast Reduce ground speed.

Broken, bent, or dull

blades

Replace blades or turn blades

over.

Replacing the Cutter Blades,

page 132

Not cutting short

enough in down

crop

Cutting height too

high

Adjust header angle to lower

cutting height if field conditions

allow.

169457

160

Rev. F