2adjusting the roll timing, Adjusting the roll timing, Operating the header – MacDon R85 Rotary Disc 16 Foot Self-Propelled Windrower Headers User Manual

Page 80: 2 adjusting the roll timing

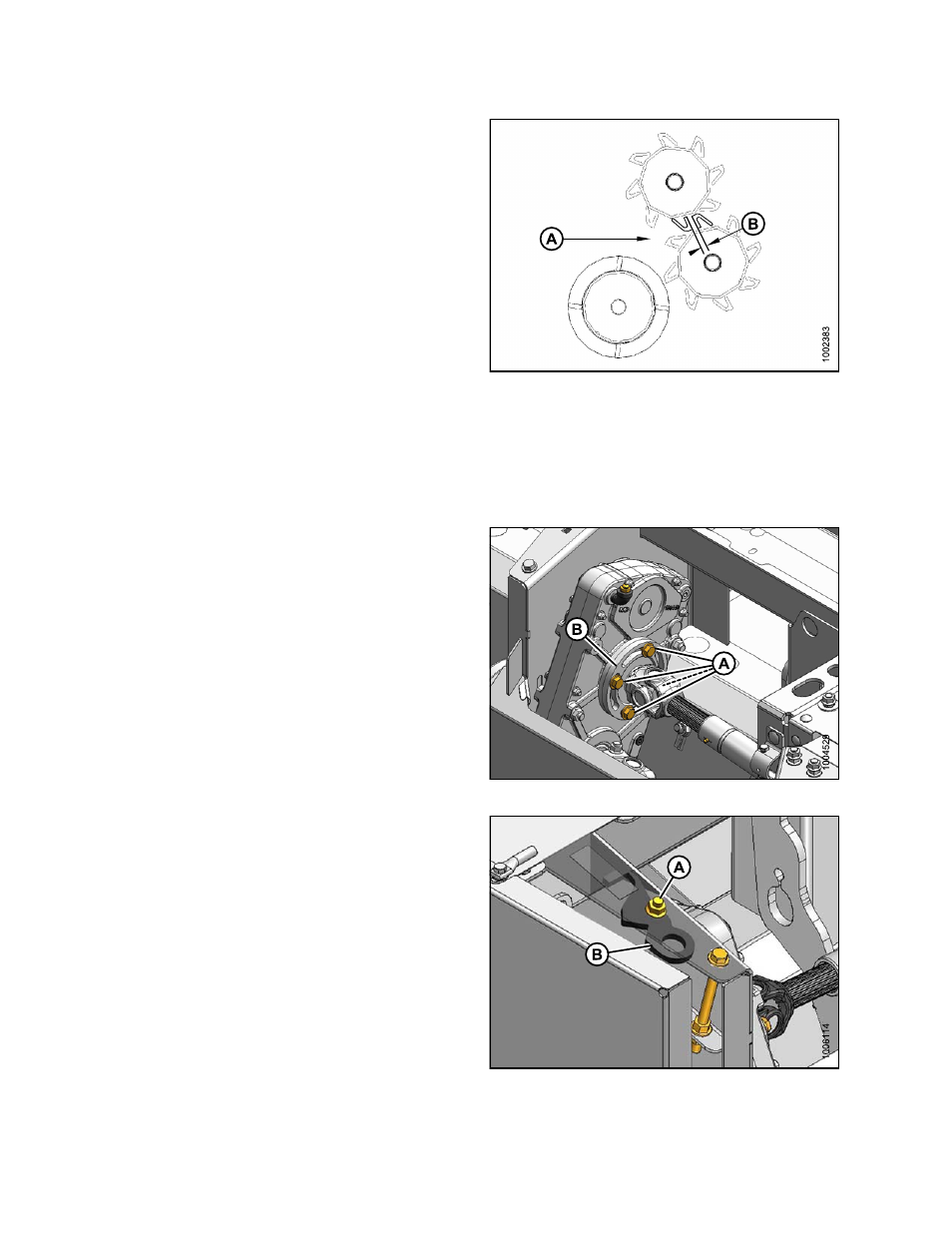

4. Measure the clearance (B) between the flats of the

conditioner roll bars at both end of the conditioner

rolls. Dimension (B) should be set to 0.35–0.51 in.

(9–13 mm). If adjustment is required, see Section

6.4.2 Adjusting the Roll Timing, page 72

NOTE: There should be less than 0.08 in. (2 mm)

difference between the two ends of the

conditioner roll.

NOTE: Roll spacing not to scale in illustration.

5. Close the driveshield. See Section

.

Figure 6.8: Roll Timing

A - Crop Flow

B - Roll Timing Distance 0.35–0.51 in. (9–13 mm)

6.4.2 Adjusting the Roll Timing

Follow these steps to adjust the roll timing (if necessary):

1. Loosen four bolts (A) in slots of yoke plate (B) on upper

roll universal shaft.

Figure 6.9

2. Locate roll timing gauge (B) on frame member under

the flange. Remove nut (A) to remove gauge.

Figure 6.10: Roll Timing Gauge

A - Nut

B - Timing Gauge MD #150572

169457

72

Rev. F