Maintenance/service diesel engine – MacDon 9250 SP User Manual

Page 68

Form # 46584

Issue 11/06 Web Rev_01

66

MAINTENANCE/SERVICE

Diesel Engine

LUBRICATING OIL

Changing engine oil and filter (continued)

6. Install the new filter. Turn the filter onto the

mount until the gasket contacts the filter head.

Tighten the filter an additional 1/2 to 3/4 turn by

hand.

IMPORTANT: Do not use a filter wrench to

install the oil filter. Over-tightening can damage

the gasket and the filter.

7. Install the oil pan drain plug.

8. Fill the engine at (A) with the proper amount of

oil. See "Fuels, Fluids and Lubricants" section

for recommended oil types.

Capacity Diesel

Engine

With filter change

11 US qts (10.4L)

Without filter change

10 US qts (9.5L)

9. Operate the engine at low idle and check for

leaks at the filter and drain plug.

10. Shut off engine. Wait five minutes, then check

oil level at dipstick. If required, add or drain oil

to bring level to high mark.

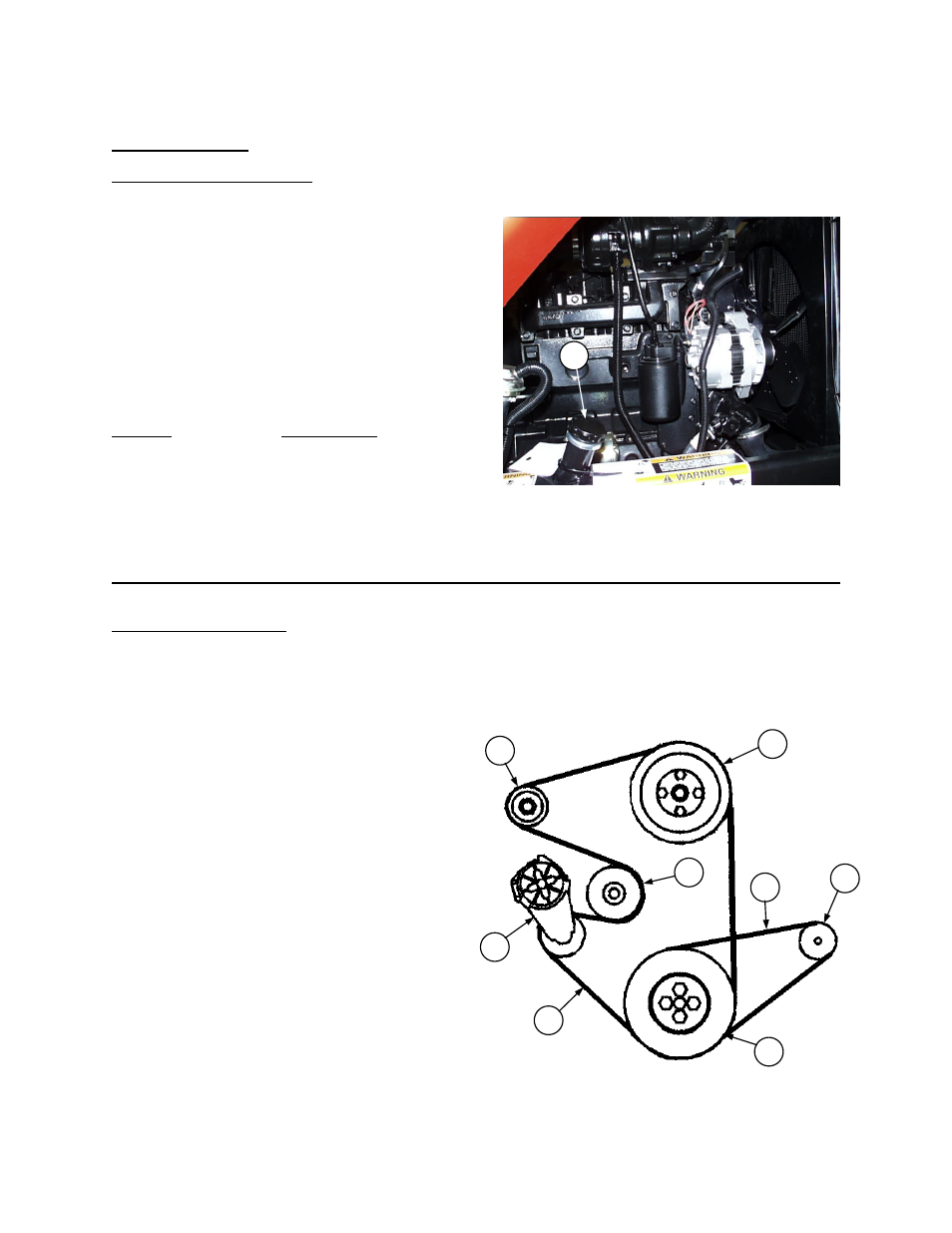

DIESEL ENGINE BELTS

The alternator/water pump/fan belt is automatically

tightened. No manual adjustment is required. See

installation procedure at right.

NOTE: When installing new compressor belt (G),

never pry belt over pulley. Loosen necessary

hardware and adjust belt tension. Re-adjust

tension of a new belt after a short run-in period.

(About 5 hours.)

To adjust compressor belt:

1. Loosen compressor mounting hardware.

2. Adjust tension so that a force of 8 to 12 lbs. (35

to 55 N) deflects belt 3/16 inch (5 mm) at mid-

span.

3. Tighten compressor mounting hardware and

recheck tension.

A - Air Conditioning Compressor

B - Alternator

C - Water Pump

D - Fan Pulley

E - Crankshaft Pulley

F - Automatic Belt Tightener

G - Compressor Belt

H - Alternator/Water Pump/Fan Belt

NOTE: For easiest installation of new belt (H):

Install around pulleys (E), (D), and (B), then raise

tensioner (F) and install on pulley (C). Lower

tensioner and check belt is properly seated in all

pulley grooves.

BELTS - DIESEL ENGINE

B

C

D

E

F

G

A

H

A

OIL FILLER LOCATION

(view from right side of windower)