Maintenance – Multiquip AR13HAR User Manual

Page 26

page 26 — aR13Ha/aR13HaR ROLLeR (s/n 110301 & up) • OpeRaTiOn anD paRTs manuaL — Rev. #0 (06/22/11)

FORWaRD/ReveRse HYDRauLiC pRessuRe

TesT

1. Park the machine on a solid flat surface and stop the

engine. Set the parking brake and block the front drum

securely.

2. Check hydraulic oil level by viewing the hydraulic oil

sight glass. The hydraulic oil level must be below the

top and above the bottom of the sight glass. DO NOT

OVERFILL!

3. Adjust engine RPM (3,500 +/- 50 RPM).

4. Let engine run for 5 minutes, this will bring the hydraulic

oil operating temperature to a minimum of 135° F.

5. Check and repair all hydraulic leaks.

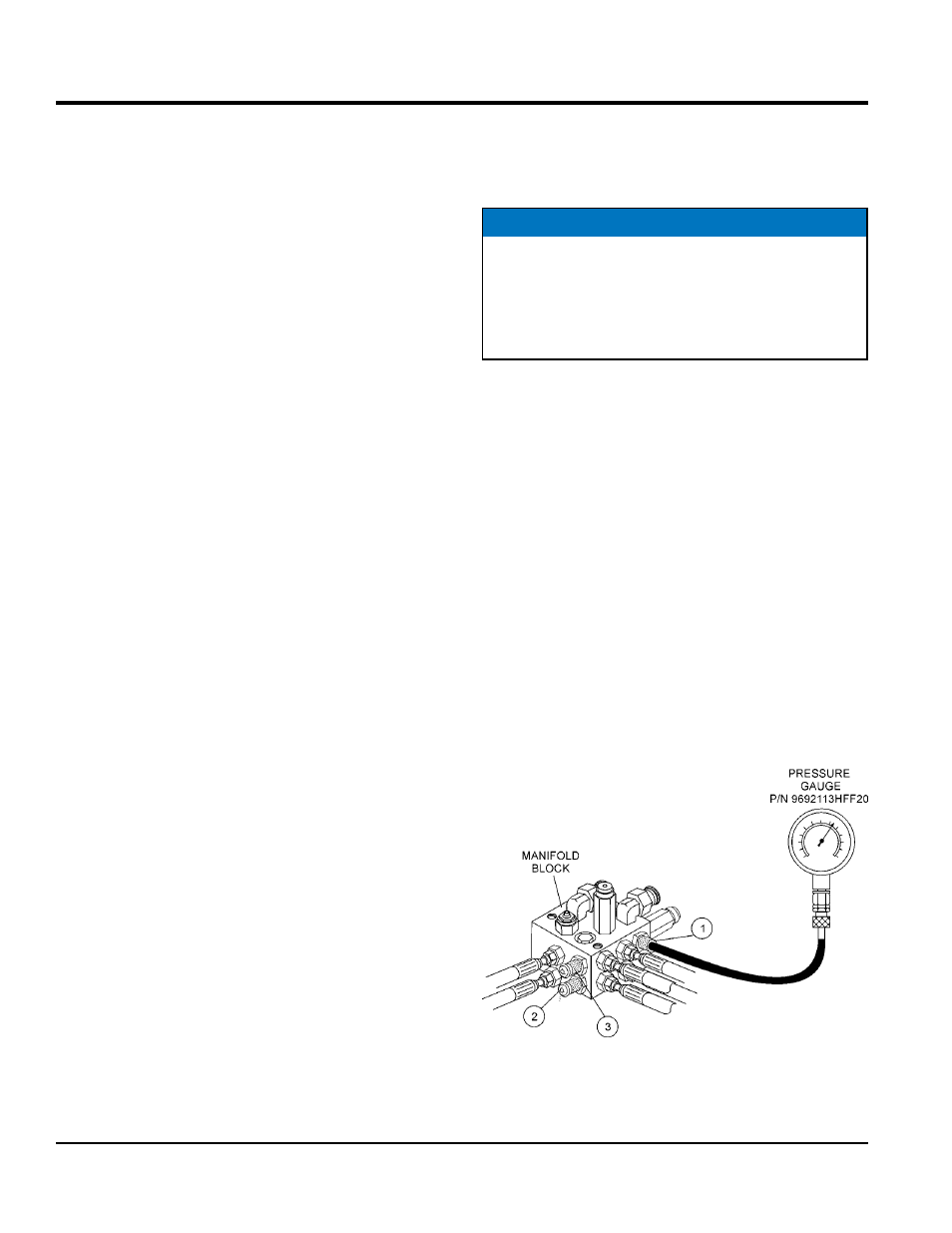

6. On the manifold block, install a 5,000 psi pressure

gauge (Figure 29) to the forward pressure quick

disconnect test port 2.

7. Run engine at full throttle.

8. Move the travel lever to the forward position. MAKE

SURE FRONT AND REAR DRUMS DO NOT SPIN.

9. Read the pressure gauge. The relief pressure (roller

drums blocked) will read 2,900 ± 145 psi. Under normal

operating conditions this pressure will read 400-600 psi.

10. Return the travel lever to the neutral position and stop

the engine.

11. Install the pressure gauge into the reverse quick

disconnect port 3 and repeat the above procedures.

The relief pressure reading for the reverse test port 3

will be the same (2,900 psi). Again normal operation

pressure for the reverse port will be 400-600 psi.

12. Normal operating pressures are based on the machine

traveling on level, firm surface. The operating pressures

will increase significantly when traveling uphill.

viBRaTiOn CiRCuiT pRessuRe TesT

1. Place the front drum on soil, gravel, or a heavy rubber

mat. DO NOT ACTIVATE VIBRATION FEATURE ON

CONCRETE OR HARD SURFACE!

2. On the manifold block install a 5,000 psi pressure

gauge to quick disconnect test port 1.

3. Start the engine and run at full throttle.

MaintenanCe

4. To start the vibration, press the pushbutton switch

(vibration control) located on top of the travel lever.

Under normal operating conditions this pressure will

range between 900-1,500 psi.

sTeeRing pRessuRe TesT

1. On the manifold block, install a 5,000 psi pressure

gauge into quick disconnect test port 1 (Figure 29).

2. Start the engine and run at full throttle.

3. Turn the steering wheel to the left or right (maximum)

and hold. Read the steering relief pressure. The relief

pressure reading for the steering test port 1 will be 700

psi. Again, under normal operating conditions, pressure

for the steering port will be between 200-400 psi.

4. If maximum pressure cannot be reached, plug the

steering cylinder pressure hoses and retest. If pressure

is correct, the steering cylinder is leaking. DO NOT

ACTIVATE THE VIBRATION FUNCTION WHILE

PERFORMING THIS TEST!

Figure 29. Manifold Test Ports

NOTICE

Vibration relief pressure is hard to read accurately using

this test. It may be necessary to disconnect the pressure

line to the vibration drive motor. Plug this line and retest,

pressure will be exact relief pressure. DO NOT perform

this test for a long period of time — damage could occur.