Maintenance, Hydraulic oil system, Changing hydraulic oil and filters – Multiquip AR13HAR User Manual

Page 24: Freewheel engagement valve

page 24 — aR13Ha/aR13HaR ROLLeR (s/n 110301 & up) • OpeRaTiOn anD paRTs manuaL — Rev. #0 (06/22/11)

HYDRauLiC OiL sYsTem

The hydraulic system consists of a two-pump stack directly

coupled to the engine. A hydraulic valve block (manifold)

is provided for quick and easy testing and troubleshooting.

Hydraulic oil is filtered by a screen filter located in the tank

filler neck, a 40 micron suction filter located in the tank, and

a 10 micron return filter, with cold oil bypass valve located

in the return circuit.

It is recommended that ISO 46 type hydraulic oil or

equivalent be used when adding or replacing the hydraulic

oil is required.

DO NOT USE MULTI-VISCOSITY OIL. Cleanliness is a

very important part of proper hydraulic system operation.

Hydraulic oil is not only used to transfer power; it also

lubricates and cools the system components. Keeping

the hydraulic system clean can help reduce costly repairs.

The hydraulic oil level sight glass is located on the right

rear of the front drum, below the engine compartment. This

level should be checked daily. Oil must be below the top and

above the bottom of the sight glass. DO NOT OVERFILL!

Care should be taken to clean the filler cap before adding oil

to the system. If hydraulic oil has to be added, the machine

should be inspected for leaks.

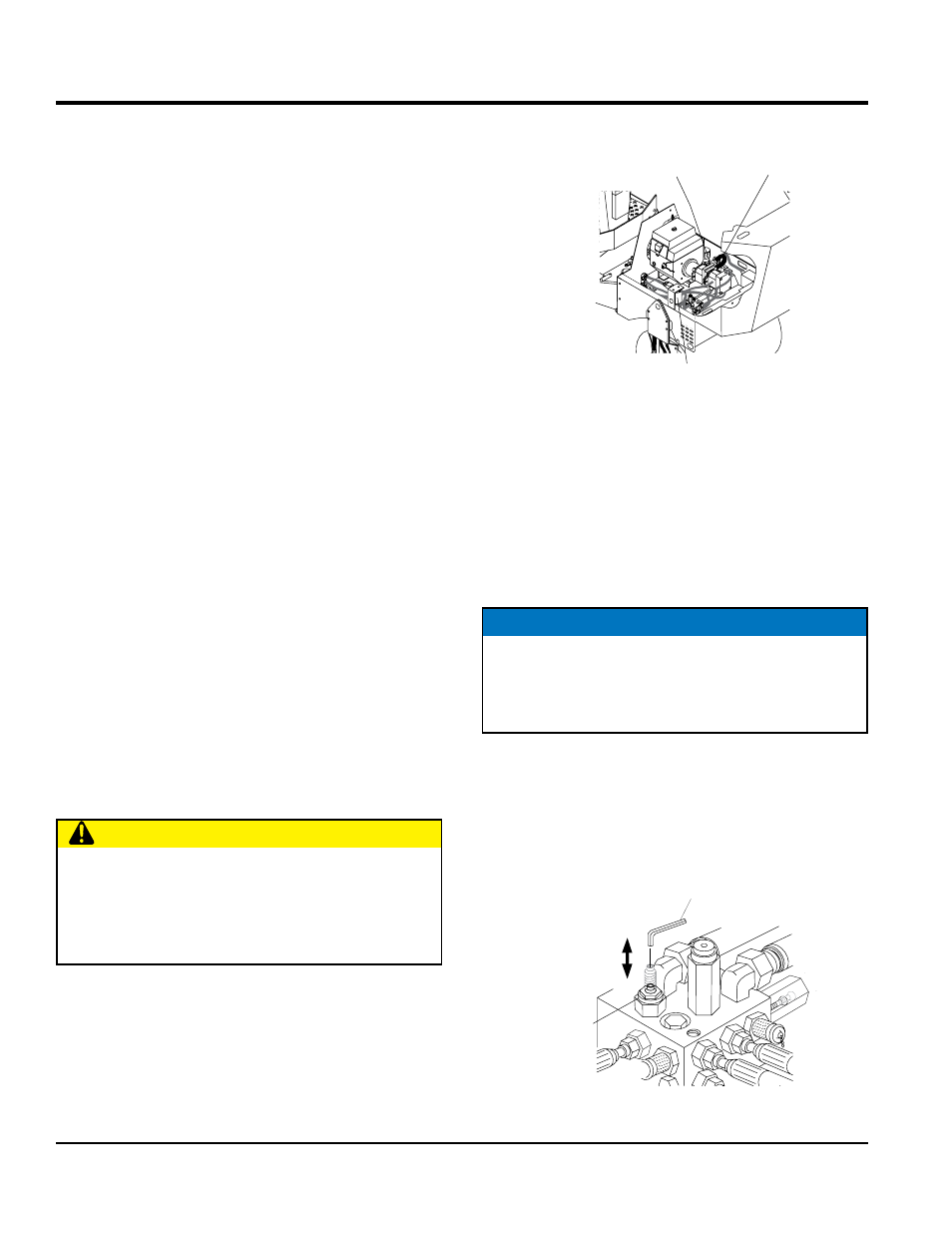

The suction filter (Figure 26) is located inside the hydraulic

tank. This filter is attached to the fitting connected to the

hydraulic pump suction hose.

The return filter (Figure 26) is located at the front of the

engine compartment. Replace both filters according to the

Table 5.

CHanging HYDRauLiC OiL anD FiLTeRs

1. Park the roller on a clean flat work area and set the

parking brake.

2. Remove the hydraulic oil drain plug (Figure 26) and

drain the hydraulic oil. Dispose of the used oil in an

CauTiOn

DO NOT open hydraulic lines or loosen hydraulic fittings

while engine is running! Hydraulic fluid under pressure

can penetrate the skin, blind, cause burns or create

other potentially dangerous hazards follow all safety

instructions as described throughout this manual.

MaintenanCe

environmentally friendly manner. Replace the drain

plug and tighten.

Figure 26. Hydraulic Filter Locations

3. Remove the return filter and install a new filter. Dispose

of the used filter in an environmentally friendly manner.

4. Disconnect the suction hose and remove the fitting from

the tank. Replace the suction filter. Dispose of the used

filter in an environmentally friendly manner. Replace

the fitting and reconnect the suction hose.

FReeWHeeL engagemenT vaLve

This hydraulic system has a freewheel engagement valve

allowing hydraulic oil to be bypassed. Open (turn allen

wrench counter-clockwise) this valve (Figure 27) to engage

the freewheel capability of the roller. When the valve is fully

opened, ports A and B are allowed to connect, bypassing

the oil to and from the drum drive motors.

Figure 27. Freewheel Engagement Valve

HYDRAULIC

OIL DRAIN

PLUG

HYDRAULIC OIL

RETURN FILTER

HYDRAULIC OIL

SUCTION FILTER

HYDRAULIC OIL

CAP/FILLER PORT

NOTICE

The freewheel engagement valve (towing) is only for

emergency use. DO NOT move roller over 2 MPH or

long distances as hydraulic system component failure

could result..

TOW

FREEWHEEL

ENGAGEMENT

VALVE

ALLEN

WRENCH

OPEN

CLOSED