Maintenance – Multiquip AR13HAR User Manual

Page 25

aR13Ha/aR13HaR ROLLeR (s/n 110301 & up) • OpeRaTiOn anD paRTs manuaL — Rev. #0 (06/22/11) — page 25

MaintenanCe

Remember the freewheel engagement valve should only

be used in emergencies when the roller cannot be driven

due to engine or hydraulic system problems.

When towing of the roller has been completed, this

valve must be closed (turn allen wrench fully clockwise)

completely and the lock nut set. Failure to close this valve

completely will result in low power, improper speed, and

excessive hydraulic oil temperature.

DRum DRive

The drum drive circuit is a parallel, closed loop system

consisting of a hydrostatic pump, two relief valves, a

freewheel engagement valve, and front and rear drum

drive motors.

The hydrostatic pump is manually controlled by a cable

connected to the forward/reverse shift lever located on the

right side of the operator seat. When the shift lever is placed

in forward, high-pressure oil is supplied by the hydrostatic

pump to the valve block (port A). The valve block (manifold)

directs this high-pressure oil to the front and rear drum

drive motors. Return oil from the motors is returned to the

valve block (port B) and is returned to the suction side of

the hydrostatic pump.

When shifted into reverse, the high-pressure and suction

ports on the hydrostatic pump are reversed. Oil flow is

then in the opposite direction of forward (port B becomes

high-pressure and port A becomes suction).

viBRaTiOn anD sTeeRing

The vibration and steering system is an open loop circuit

operated by a gear type pump. Separate relief valves control

each circuit. This system consist of the gear pump, relief

valves, electric vibration control valve, vibration drive motor,

steering valve, and steering cylinder.

The vibration circuit is controlled by an electric control

valve located on the valve block (manifold). This valve is

controlled by the “ON/OFF” pushbutton switch mounted on

top of the travel lever.

High-pressure oil is supplied by the pump to the valve block

(port P) and is directed to the electric control valve. When

the pushbutton switch is in the “OFF” position, this valve is

open allowing oil to go to the steering valve, without driving

the vibration motor.

When the switch is in the “ON” position, the electric control

valve closes and oil is directed out of port 1 to the vibration

motor. Return oil from the motor returns to the valve block

via port 2 and is directed to the steering valve.

Steering is controlled by a steering valve and cylinder.

The steering wheel is direct coupled to the steering valve

controlling the oil flow to the cylinder. Oil supplied from the

vibration circuit is directed to port 3 which connects to port

P of the steering valve. When steering is not being used,

oil passes out of port T of the valve block and returns to

the hydraulic tank. When the steering wheel is operated,

the steering valve closes and oil is directed to ports L or R

to extend or retract the steering cylinder.

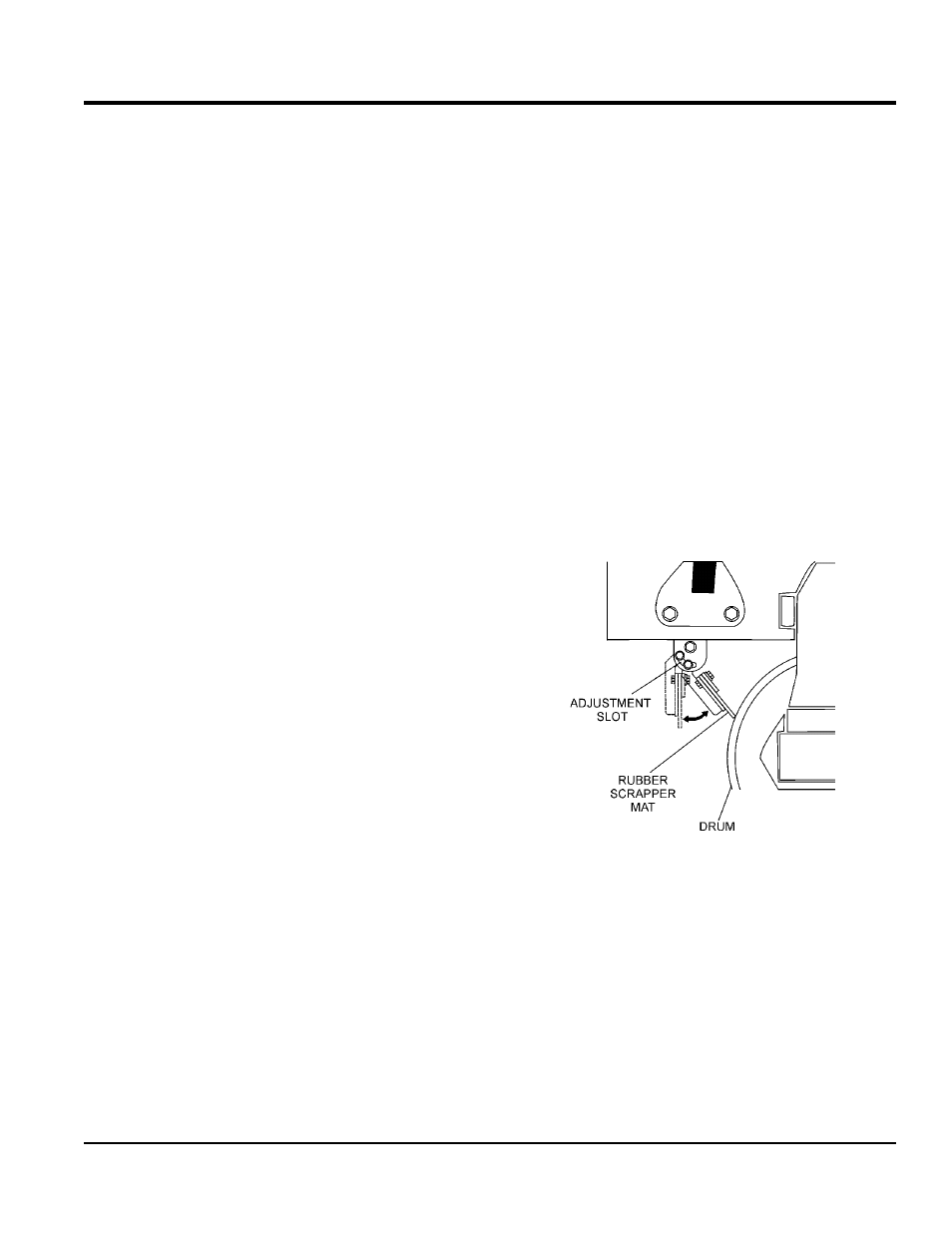

RuBBeR sCRappeR maT

Rubber scraper mats have been provided for the cleaning

of the front and rear drums. Adjust the scrapers mats as

close as possible to the drums, using the slotted holes

(Figure 28) provided. Replace these rubber mats when

they become badly worn.

Figure 28. Scraper Bar Adjustment