Checking the low level/temperature detector, Checking the low level/temperature detector 93 – MTS Series 505 SilentFlo Hydraulic Power Unit Model 505-180 User Manual

Page 93

Checking the Low Level/Temperature Detector

Model 505.60 - 505.180 SilentFlo™ HPU

Maintenance

93

5. Check and adjust the hydraulic fluid delivery system so that:

•

Hydraulic fluid temperature stabilizes within the parameters given in

the Specifications table when the HPU is operating at high pressure.

•

Pressure line reading is maintained at 21 MPa (3000 psi) maximum

static value.

•

Maximum drain line back pressure is limited to 0.1 MPa (15 psi).

If you need to adjust the water-regulating valve, over-temperature switch or

pressure control valves, refer to the procedure on changing the water flow.

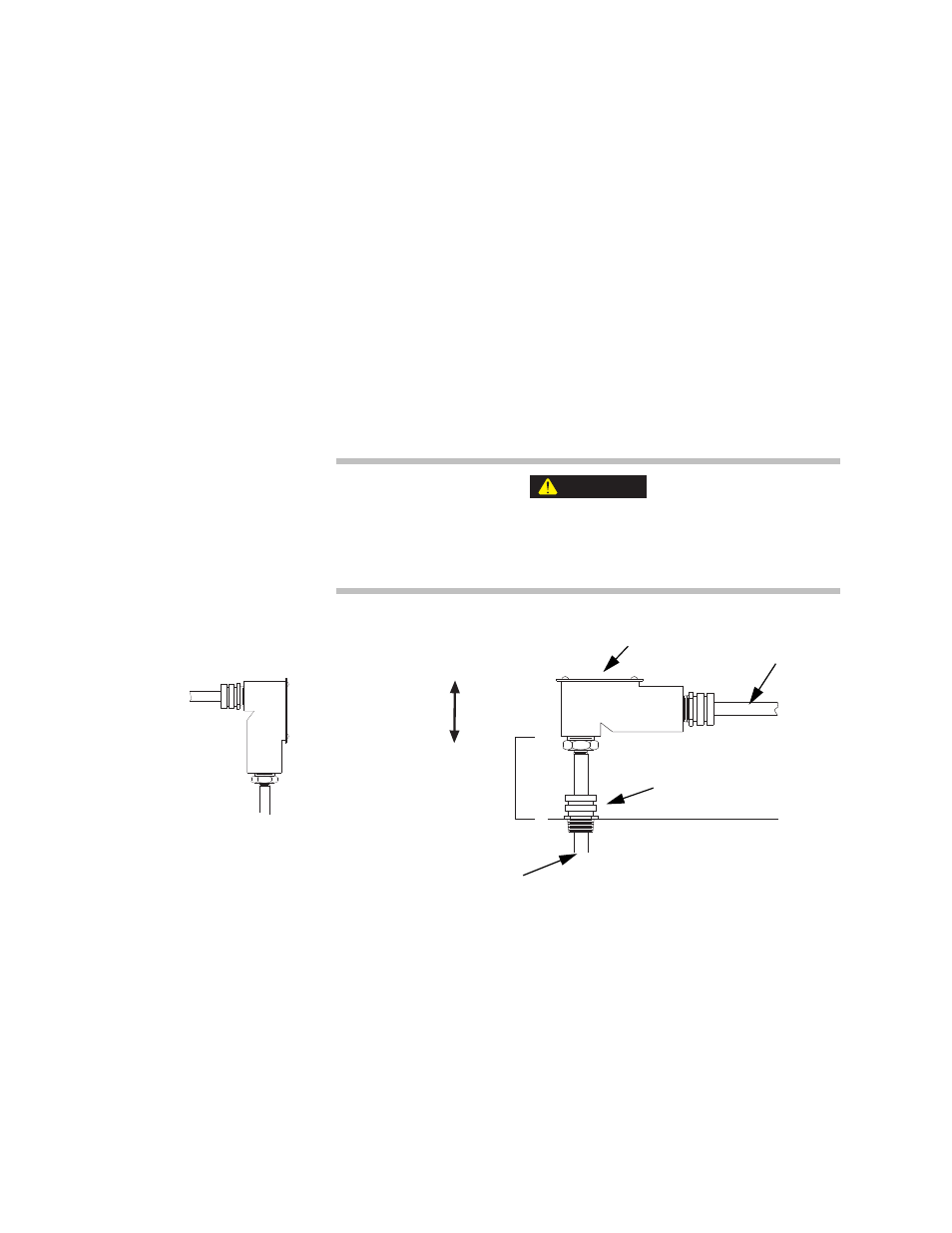

Checking the Low Level/Temperature Detector

The low level/temperature fixture monitors the temperature and level of

hydraulic fluid in the reservoir. Check the functionality of the low level/

temperature detector every 6 months.

Running the pump motors with hydraulic fluid below the top of the motors

can cause them to fail.

The low level position is factory set. Set the replacement fixture to the same level.

How to check the low

level switch

1. Note the distance between the head assembly of the fixture and the top of

the reservoir.

2. Turn on power to the hydraulic power unit.

3. Loosen the locknut on top of the reservoir that holds the assembly in place.

4. Raise the low level assembly high enough to cause the HPU Run Status to

flash between Faulted and Low Level. If the Low Level does not display,

replace the low level assembly (Step 5). If the low level assembly is OK, go

to Step 6.

CAUTION

Raise/Lower the

low level assembly

Note original distance from

head assembly to reservoir

Alternate switch

orientation

Head Assembly

Locknut

Shaft

Cable

Top of Reservoir