MTS Series 505 SilentFlo Hydraulic Power Unit Model 505-180 User Manual

Page 100

Model 505.60 - 505.180 SilentFlo™ HPU

100

Sampling the Hydraulic Fluid

Maintenance

1. Operate the HPU until the hydraulic fluid is at normal operating temperature

(about 30 minutes).

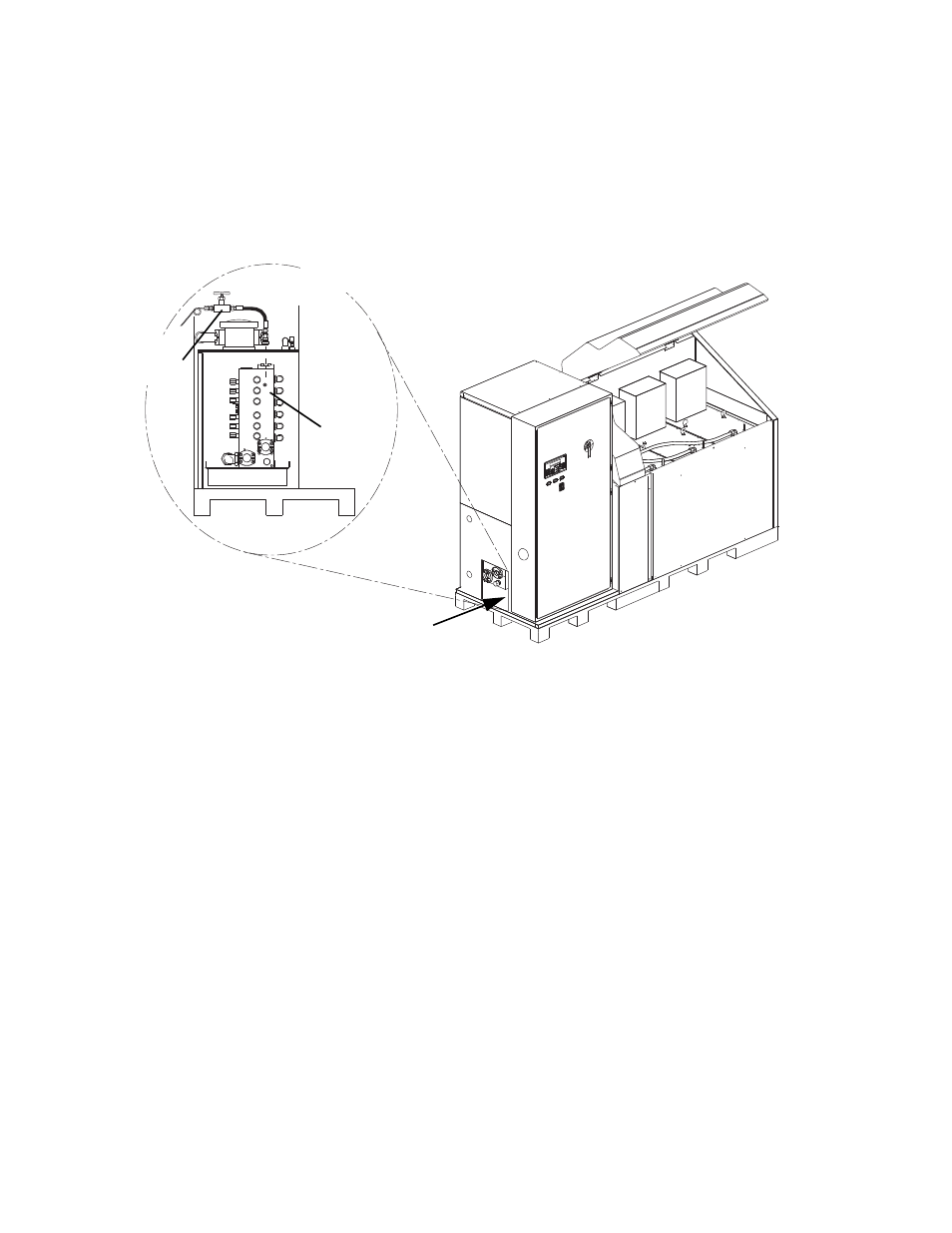

2. Open the bottom side panel to access the control manifold.

3. Close the needle valve. Connect the hose valve assembly to the sample port

located on the control manifold.

Location of Sample Port on Control Manifold

4. Open the needle valve, and flush 1 liter (1 quart) of hydraulic fluid though

the sampling assembly. This fluid can be directed to a waste container or

back into the HPU reservoir.

5. Obtain a sample of the hydraulic fluid after flushing the valve hose

assembly.

A.

Without closing the valve, quickly place the sample bottle into the fluid

stream (keep the sample bottle sealed until the sample is to be taken).

B.

Fill the sample bottle (175 mL/6 oz) with fluid.

C.

Close the valve on the hose valve assembly and cap the sample bottle.

6. Check the fluid qualities of the sample by comparing it to a small jar of

clean hydraulic fluid. Clean hydraulic fluid has an amber color.

Consult the table, “Appearance of Hydraulic Fluid Sample” for indicators of

unacceptable fluid qualities.

7. If there still is any uncertainty regarding fluid quality, obtain another sample

of the fluid and have it analyzed. The fluid tests should include chemical

analysis, particle count, and viscosity checks. Most oil companies have

facilities for performing these tests, or consult MTS Systems Corporation.

Open panel to access manifold

Control Manifold

Needle

Valve

Sample

Port

Hose Valve Assembly