6 commissioning of profibus, 1 overview of the commissioning steps, Commissioning of profibus – Lenze PROFIBUS Controller-based Automation User Manual

Page 25: Overview of the commissioning steps, 6commissioning of profibus

Lenze · Controller-based Automation · PROFIBUS® Communication Manual · DMS 4.3 EN · 04/2014 · TD17

25

6

Commissioning of PROFIBUS

6.1

Overview of the commissioning steps

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6

Commissioning of PROFIBUS

This chapter provides information on how to commission the Lenze automation system with

PROFIBUS.

Depending on the field devices used, the following

are required:

• »EASY Starter«

• »Engineer«

• »PLC Designer«

6.1

Overview of the commissioning steps

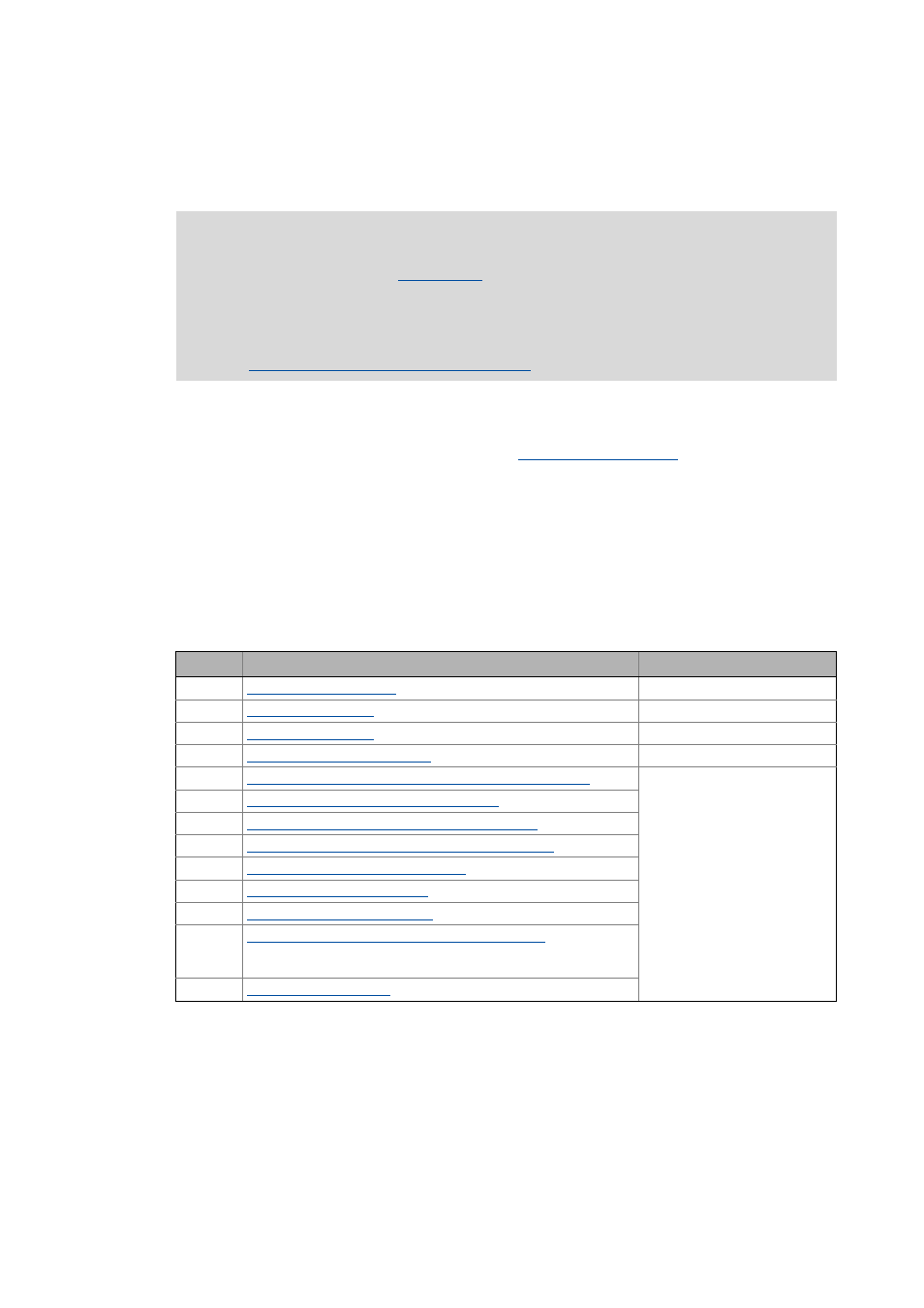

The main commissioning steps are listed in the following table:

Note!

Via PROFIBUS only Logic

can be operated in the Lenze automation

system.

Inverters which are to be controlled via the central Motion functionality must always be

connected via EtherCAT.

Mixed operation PROFIBUS with EtherCAT

Step

Activity

Software to be used

1.

Planning the bus topology ( 26)

2.

3.

4.

Commissioning the field devices ( 27)

»Engineer« / »EASY Starter«

5.

Creating a PLC program with a target system (Logic/Motion) ( 28)

»PLC Designer«

6.

Configuring the communication parameters ( 30)

7.

Importing missing devices / device description files ( 32)

8.

Creating a control configuration (adding field devices) ( 33)

9.

Configuration of the PROFIBUS master ( 37)

10.

Configuring the PROFIBUS slave ( 40)

11.

Compiling the PLC program code ( 41)

12.

Logging in on the controller with the »PLC Designer« ( 41)

With the log-in, the fieldbus configuration and the PLC program are

loaded into the Controller.

13.