Tool hold down springs, Hydraulic maintenance, Lubrication – Landoll 2000 Series Row Crop Cultivator User Manual

Page 36: Figure 4-10: lubrication schedule

4-10

F-140-0512 Edition

OPERATION AND MAINTENANCE

Tool Hold Down Springs

The hold down springs are on either side of the parallel

linkage on the tool frames and are factory adjusted for

most normal conditions. Tightening the springs increases

the ground tool pressure. Too much pressure will shorten

the life of the ground tools.

Hydraulic Maintenance

1.

Check the tractor hydraulic fluid level per tractor

owners manual and after any leakage. Check fluid

level with the cylinders in the retracted position.

2.

If a cylinder leaks, disassemble the parts to

determine the cause of the leak. Any time a cylinder

is opened up, or whenever any seal replacement is

necessary, it is advisable to clean all parts and

replace all seals Seal kits are available from your

Landoll dealer.

3.

Check all hydraulic hoses weekly, Look for binding or

cracking. Replace all worn or defective parts

immediately.

Lubrication

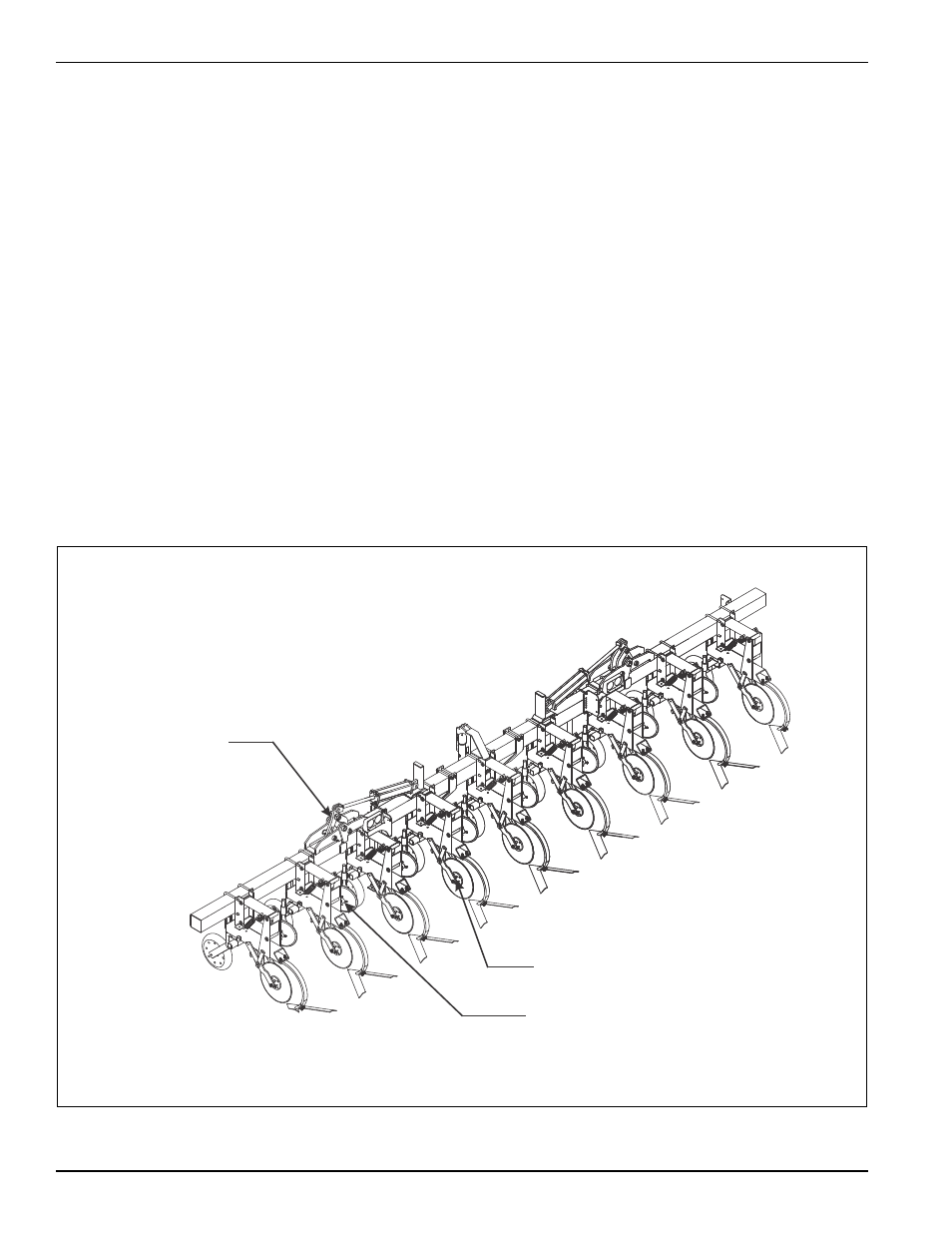

See Figure 4-10 for lubrications points and

recommended maintenance schedule.

1.

The coulter hub bearings, and disc hiller bearings

should be lubricated with a high grade multi-purpose

grease twice a day or every five hours. They should

be filled till the grease is forced past the seals. This

will not damage the seals.

2.

The wing fold pins (if applicable) should be greased

daily with a high grade multi-purpose grease.

Figure 4-10: Lubrication Schedule

HINGE POINTS

(50 HOURS)

COULTER ASSEMBLY

BEARINGS (5 HOURS)

DISC ASSEMBLY

BEARINGS

(5 HOURS)

2000b row crop lube