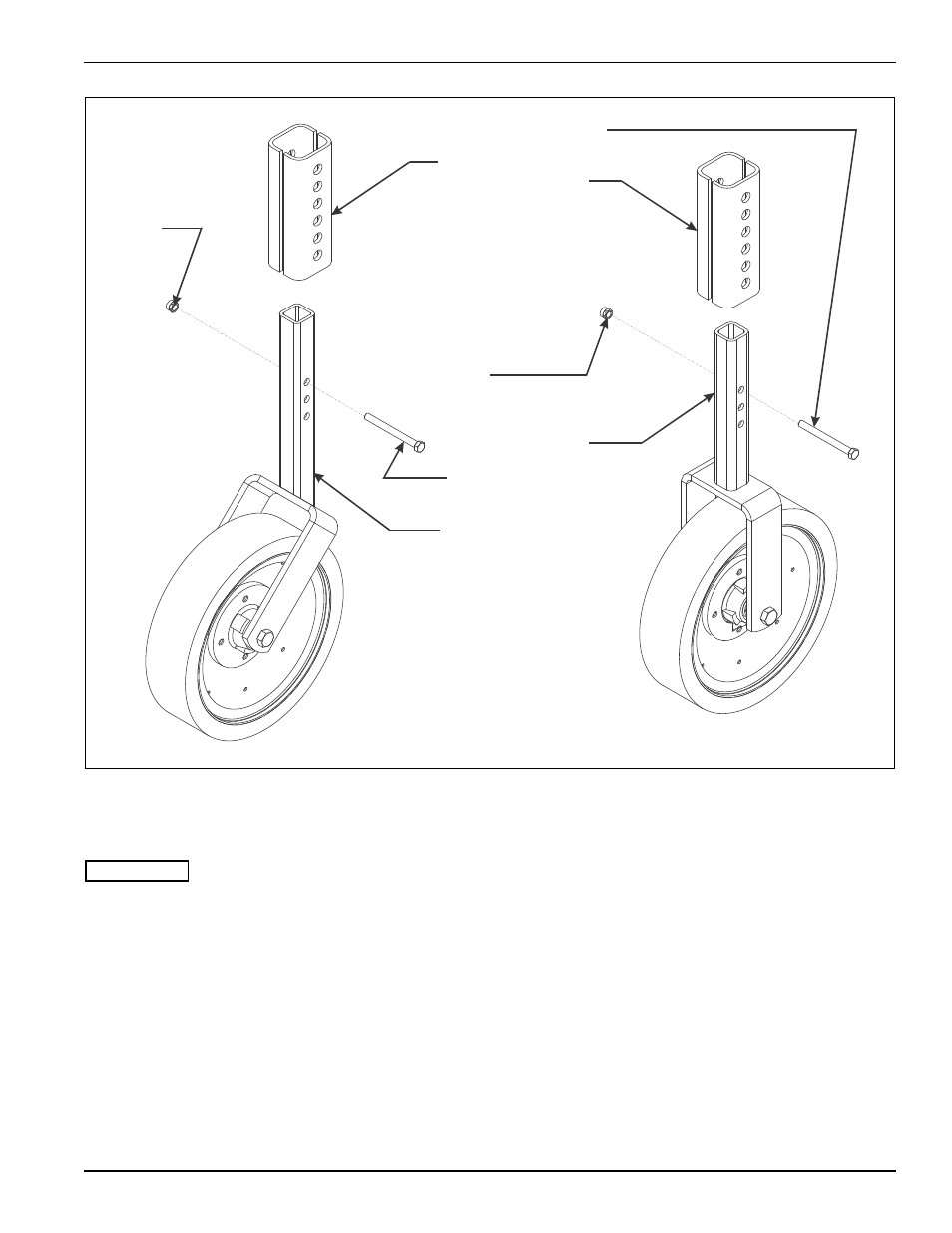

Figure 3-3: gauge wheel installation, Gauge wheel installation – Landoll 2000 Series Row Crop Cultivator User Manual

Page 15

ASSEMBLY INSTRUCTIONS

3-5

Figure 3-3: Gauge Wheel Installation

Gauge Wheel Installation

IMPORTANT

See Figure 3-3 for parts names. When assembly is

done, tighten all fastening hardware to the torques

listed in Table 2-1 and Table 2-2. Tighten u-bolts

evenly to show an even amount of thread on both

legs of the u-bolt.

1.

Find the end gauge wheel assemblies with the 45°

angle mounting forks.

2.

Remove the 1/2-13 X 3-1/2 hex head cap screw and

serrated flange head nut from the gauge wheel

brackets. These are on the front of the outer tool

frames.

3.

Slide a gauge wheel square tube up through the

bracket on each outer tool frame with the forks

pointing forward. Position the gauge wheel for proper

depth. Use the 1/2-13 X 3-1/2 hex head cap screw

and serrated flange head nut to position the gauge

wheel. Tighten the nut until wheel tube is securely

clamped into place.

4.

The remaining middle gauge wheel assemblies are

installed on the inner tool frames. They are installed

using the steps described in steps 2 through 3.

TOOL MOUNT

FRAME BRACKET

1/2-13 FLANGE

HEAD SERRATED

NUT

1/2-13 X 3-1/2 HEX

HEAD CAP SCREW

MIDDLE GAUGE

WHEEL ASSEMBLY

(INNER FRAMES)

1/2-13 X 3-1/2 HEX

HEAD CAP SCREW

END GAUGE

WHEEL ASSEMBLY

(OUTER FRAMES)

2000 gauge wheel assembly

1/2-13 FLANGE

HEAD SERRATED

NUT