Final assembly, Figure 3-14: 1,200 foot-pounds of torque, Figure 3-15 – Landoll 2111 Coulter Chisel User Manual

Page 55: Rear jack installation (option), Figure 3-16: rear jack installation, Caution

ASSEMBLY INSTRUCTIONS

3-23

Final Assembly

1.

Attach a tractor to the implement and charge the lift

system hydraulics as described in “Hydraulic Lift

System” on page 4-2.

2.

Install the 1-1/2 x 16 lockouts on both 3-1/2 x 16

cylinders on the frame.

3.

Connect lights to the tractor and verify operation.

4.

Check tires for proper inflation

5.

Level the Coulter Chisel from front to rear as

described in “Leveling (Front-to-Rear)” on

page 4-5.

6.

Inspect the final implement assembly, and verify that

all bolts have been tightened, cotter pins spread, and

that there are no leaking hydraulic connections.

CAUTION

Figure 3-14: 1,200 Foot-Pounds of Torque

7.

Rotate each disc gang to verify that each gang

rotates freely. Adjust any scrapers that may have

shifted during shipment or assembly.

8.

Lubricate the Coulter Chisel at all locations (See

“Lubrication Maintenance” on page 4-12.)

9.

Touch up with paint any areas that may have been

scratched during moving, handling, or assembly.

10. Thoroughly read and understand the operating

section before using the Coulter Chisel.

Figure 3-15:

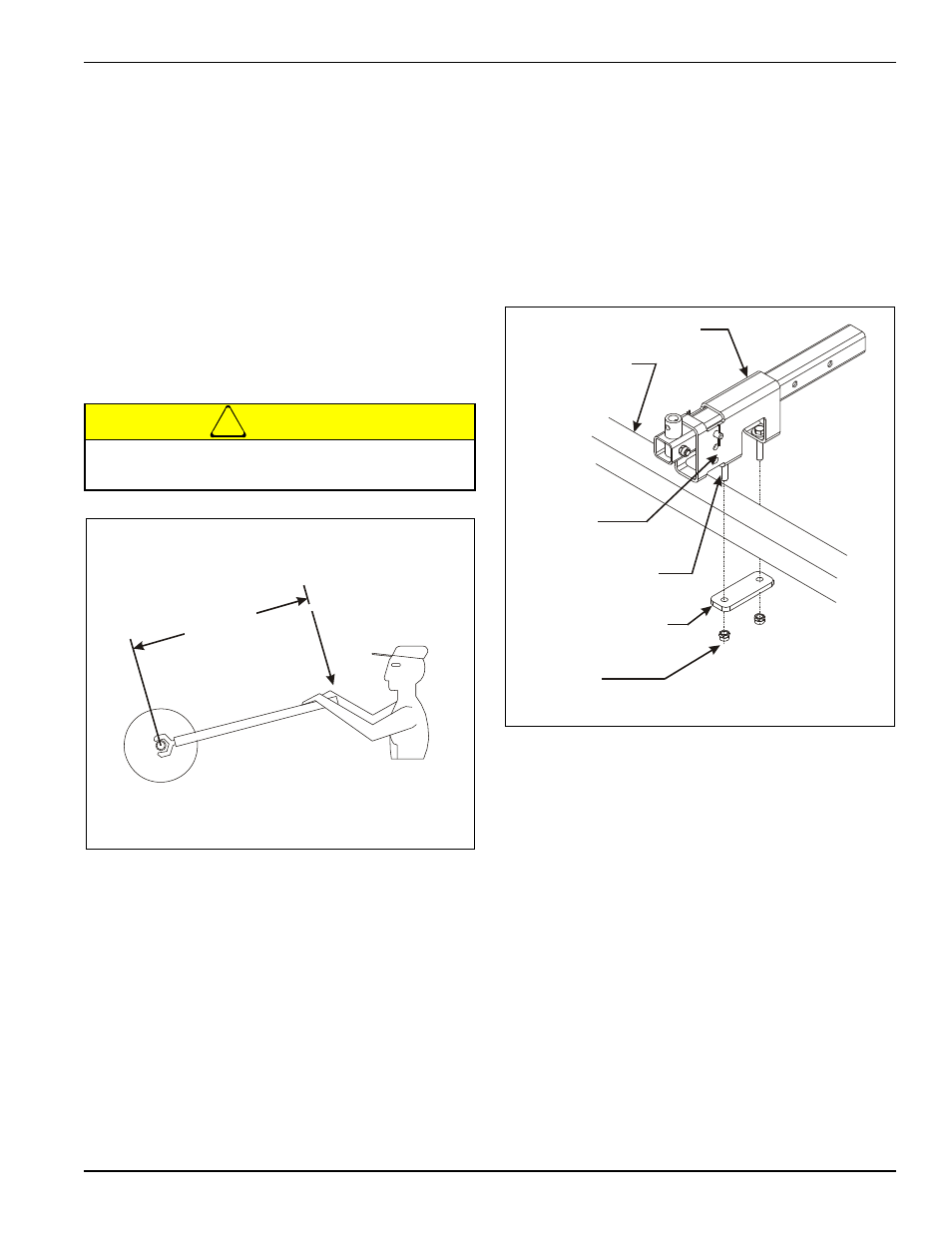

Rear Jack Installation (Option)

A rear jack assembly is available for use on the rear of

the Coulter Chisel.

1.

Slide rear jack assembly over rear frame of the

Coulter Chisel near the center of the frame (See

Figure 3-16.)

2.

Slide rear plate onto 3/4-10 x 4 hex head cap screws

beneath rear frame tube and hold in place with

3/4-10 hex lock nuts.

Figure 3-16: Rear Jack Installation

Tighten all 1-3/4” nuts to 1,200 foot-pounds of

torque (See Figure 3-14.)

300

POUNDS

PULL

4 FOOT

2md410-010943

REAR JACK ASSEMBLY

REAR FRAME

3/4W FLAT

WASHER

3/4-10 X 4 HEX HEAD

CAP SCREW GR5

REAR JACK PLATE

3/4-10 HEX LOCK

NUT GRB

m156953 installation