Able, 19 p, Robe – INFICON Maxtek PM-700 Plating Monitor User Manual

Page 69: Egister

PM-700 SERIES PLATING MONITOR

61

The displayed rate, thickness, and efficiency values are absolute. Their negative

sign bits are stored in the probe flag register and are bit mapped as follows:

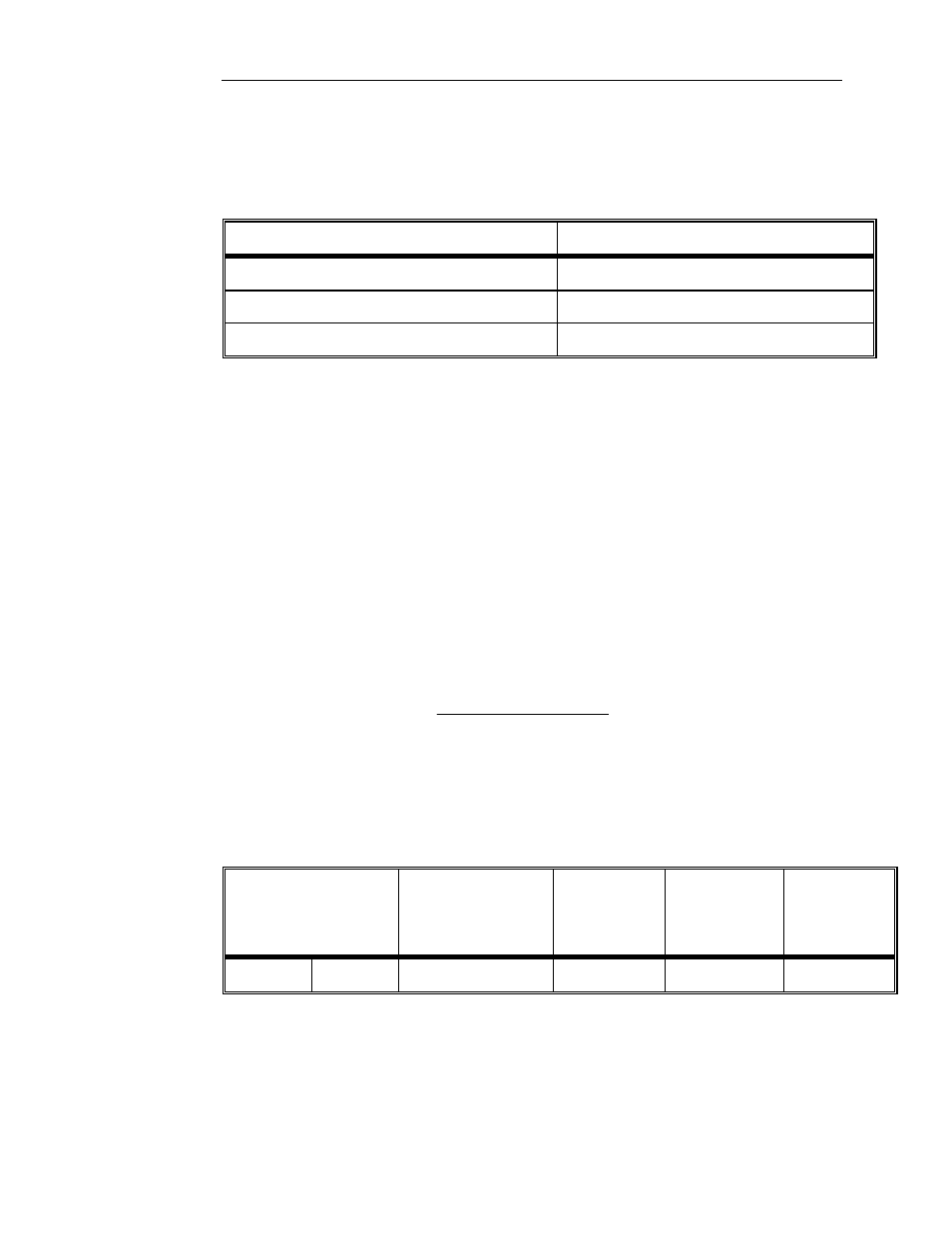

Table 19 Probe Flag Register

Bit No.

Description

5

Negative sign (display thickness)

6

Negative sign (display rate)

7

Negative sign (display efficiency)

The current value is in the units of counts and ranges from 1 to 2999. To convert

this value to the displayed value, multiply by the current scale factor/256

2

and

divide by 10*current decimal point position. This value is an absolute value for

the probe current. Bits 0, 1, 2, and 3 of the Output2 register determine whether

the current is positive or negative or none at all. The bit map for the Output2

register is shown in Table 17 on page 57.

If bits 0 and 1 of the Output2 register are false (=0), then the output current to the

probe-A is zero regardless of the probe current value. But, if bit 0 is true, then the

output current is positive. Or, if bit 1 is true, then the output current is negative.

One important note is that the PM-710 and PM-740 output probe period instead of

the probe frequency. To convert the period to frequency, use the following

equation:

To initiate automatic data logging, the computer would send a one byte message

in the standard format. The variables will be sent in the order they are displayed

in above. For example, to setup the monitor to automatically output the displayed

rate and thickness, the following message would be sent to the monitor:

Header

(2 bytes)

Instruction Code

(1 byte)

Message

Length

(1 byte)

Command

Code or

Message

Checksum

(1 byte)

FFh FEh 50h

1h

3h

ABh

(

)

Period

f

2

6

256

*

500

*

10

*

3

.

98

=