Sample process, Ample, Rocess – INFICON Maxtek PM-700 Plating Monitor User Manual

Page 23: Able, Arameter, Alues

PM-700 SERIES PLATING MONITOR

15

3.1 SAMPLE

PROCESS

Suppose a PM-700 monitor is to be used to continuously measure the plating rate

and thickness in an electroless nickel bath, giving a deposit with 6%

phosphorus. Since this bath will not initiate plating on a pure gold surface, the

sensor crystal will have to be electrolytically preplated with, for example, .5

microns of nickel at a controlled rate in order to support subsequent autocatalytic

electroless plating. Assume that the desired plating thickness endpoint is 20

microns and it is desired that the plating monitor warns the operator if the plating

rate falls outside the normal limits of .100 ±0.02 micron/min. It is also desired

that the total elapsed time since introduction of the work into the plating bath be

displayed. These parameters will be established for process number 3.

Given the above example, the following list of parameters will need to be

programmed into the monitor.

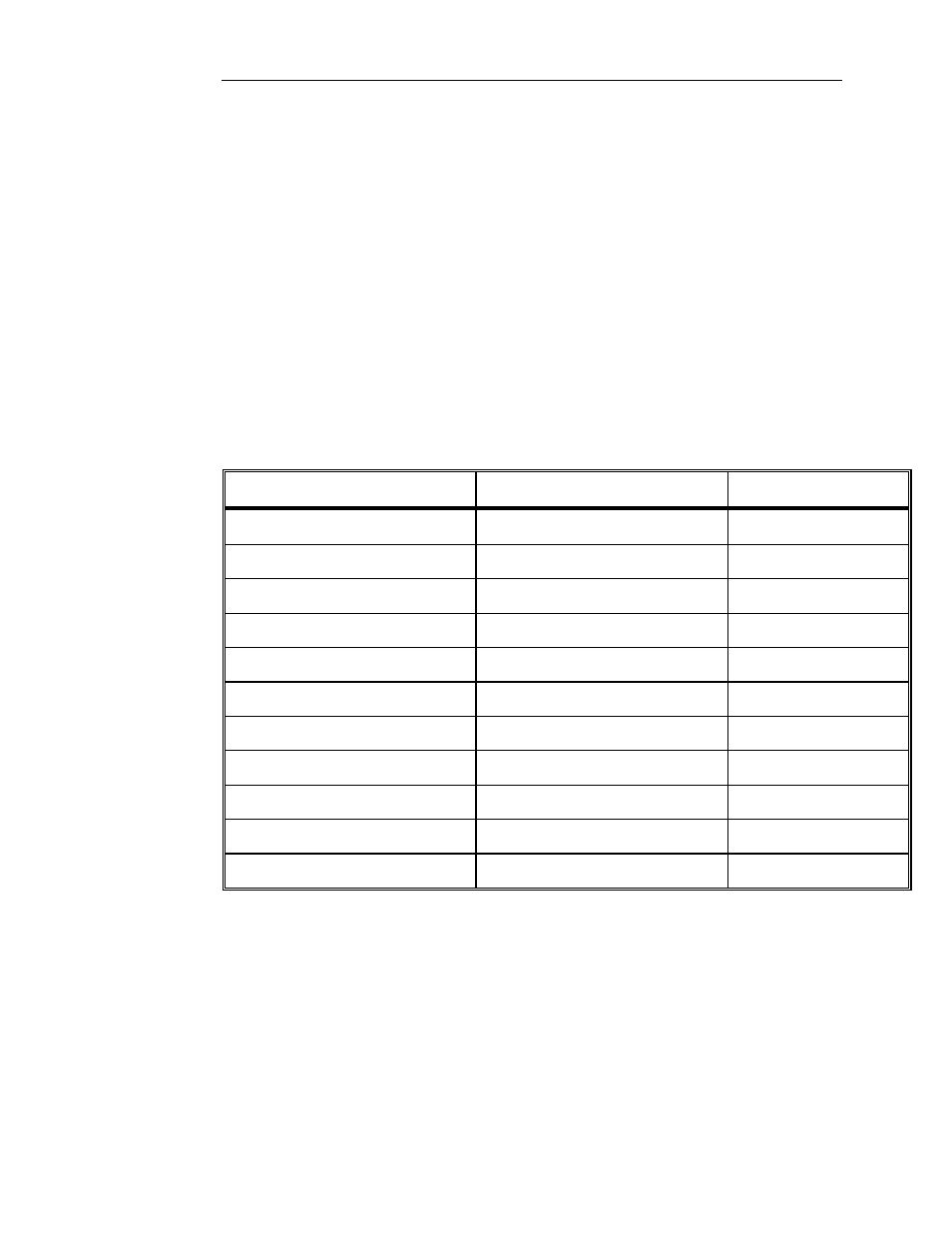

Table 2 Sample Process Parameter Values

Menu

Parameter

Value

Process Menu

Process

Number 3

Process Menu

Endpoint Setting

20.00

Process Menu

Min Rate Alarm

0.080

Process Menu

Max Rate Alarm

0.120

Mode Menu

Sample

Off

Bath Menu

Bath

Ni 6%P

Bath Menu

Type

Elecless

Bath Menu

Preplate Thckness

0.500

Bath Menu

Preplate Rate

0.050

Display Menu

Parm Status Display

Elaptime

Setup Menu

Simulate

Off

Since the above parameters will be established for process number 3, the first

thing to do is select process number 3 as the current process. You can do this by

going to the Process parameter in the Process Menu and use the SELECT arrow

buttons to find Number 3. Then follow the above list to program the rest of the

parameters.