6 replacing the bellows assembly [lpn 750-286p2 – INFICON CrystalSix Sensor User Manual

Page 48

4 - 12

IP

N 07

4-

15

5L

CrystalSix Operating Manual

4.6 Replacing the Bellows Assembly

[lPN 750-286-P2]

Reference

.

Equipment required:

1 /16" allen wrench

3/32" allen wrench

Alignment tool assembly 750-254-G1

Regulated air supply 80-90 PSIG (5.5 bar - 6.2 bar) [550 kPa - 620 kPa]

1

Remove the two #4-40 fasteners that secure the actuator cover (item #15) to

the top plate (item #10). Remove the heat shield (item #8) by gently pulling on

the outside circumference of the shield. The shield should snap off.

2

Advance the carousel (item #5) using the crystal switch button on the handheld

controller or on the controller front panel as many times as necessary until the

alignment holes in the sensor body (item #11), carousel assembly (item #5) and

the top plate (item #10) coincide.

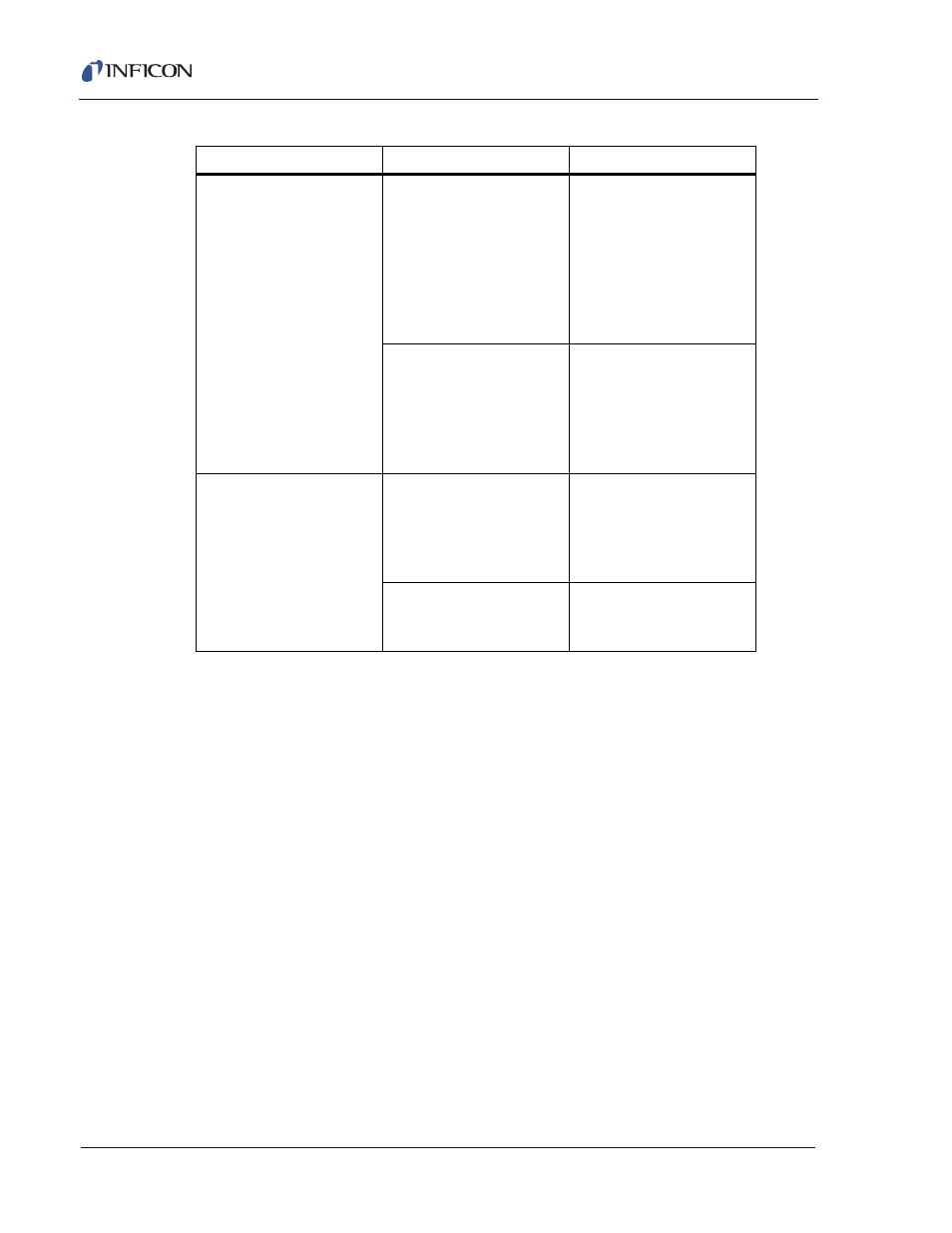

9. Poor thickness

reproducibility

9a. Erratic source

emission characteristics.

9a. Move sensor to a

different location; check

the evaporation source for

proper operating

conditions; insure

relatively constant pool

height and avoid tunneling

into the melt.

9b. Material does not

adhere to the crystal.

9b. Check the cleanliness

of the crystal surface;

evaporate an intermediate

layer of proper material on

the crystal to improve

adhesion.

10. Sensor jamming

10a Crystal holders come

loose and jam sensor

during rotation. May be

caused by absence of

orifice in airline.

10a. Check for orifice, see

.

10b. Electrical contacts on

carousel may be damaged

if unit was counter rotated.

10b. Replace contacts.

Table 4-1 Troubleshooting (continued)

Symptom

Cause

Remedy