1 installation requirements, 1 feedthrough, 2 other – INFICON CrystalSix Sensor User Manual

Page 10: 3 utilities

1 - 2

IP

N 07

4-

15

5L

CrystalSix Operating Manual

1.1.1 Installation Requirements

1.1.1.1 Feedthrough

Qty (1) 2-3/4" ConFlat® with two coaxial feedthroughs, two pass water, one air

IPN 002-080, See

or,

Qty (1) 1" bolt with one coaxial feedthrough, two pass water, one air IPN

750-030-G1, see

1.1.1.2 Other

User to provide vacuum-tight braze joints or connectors for the water and air

tubes.

Valve assembly for air, IPN 750-420-G1 (not provided), with a 0.022" restrictor

orifice installed by the user. (Orifice included with CrystalSix accessory kit.) See

.

XIU or Oscillator designed to interface with the deposition controller.

Deposition controller must have been designed for this specific crystal sensor

(INFICON® XTC/2, XTC/C, IC/4, IC/4 PLUS, IC/5).

1.1.1.3 Utilities

Minimum water flow 150-200 cc/min, 30 °C max (Do not allow water to freeze).

Coolant should not contain chlorides as stress corrosion cracking may occur.

Regulated air supply 80-90 PSIG (5.5 bar - 6.2 bar) [550 kPa - 620 kPa]

2 meter maximum length of 1/8" tubing between bellows assembly and the

control valve.

CAUTION

Do not allow water tubes to freeze. This may happen if the

tubes pass through a cryogenic shroud and the fluid’s

flow is interrupted.

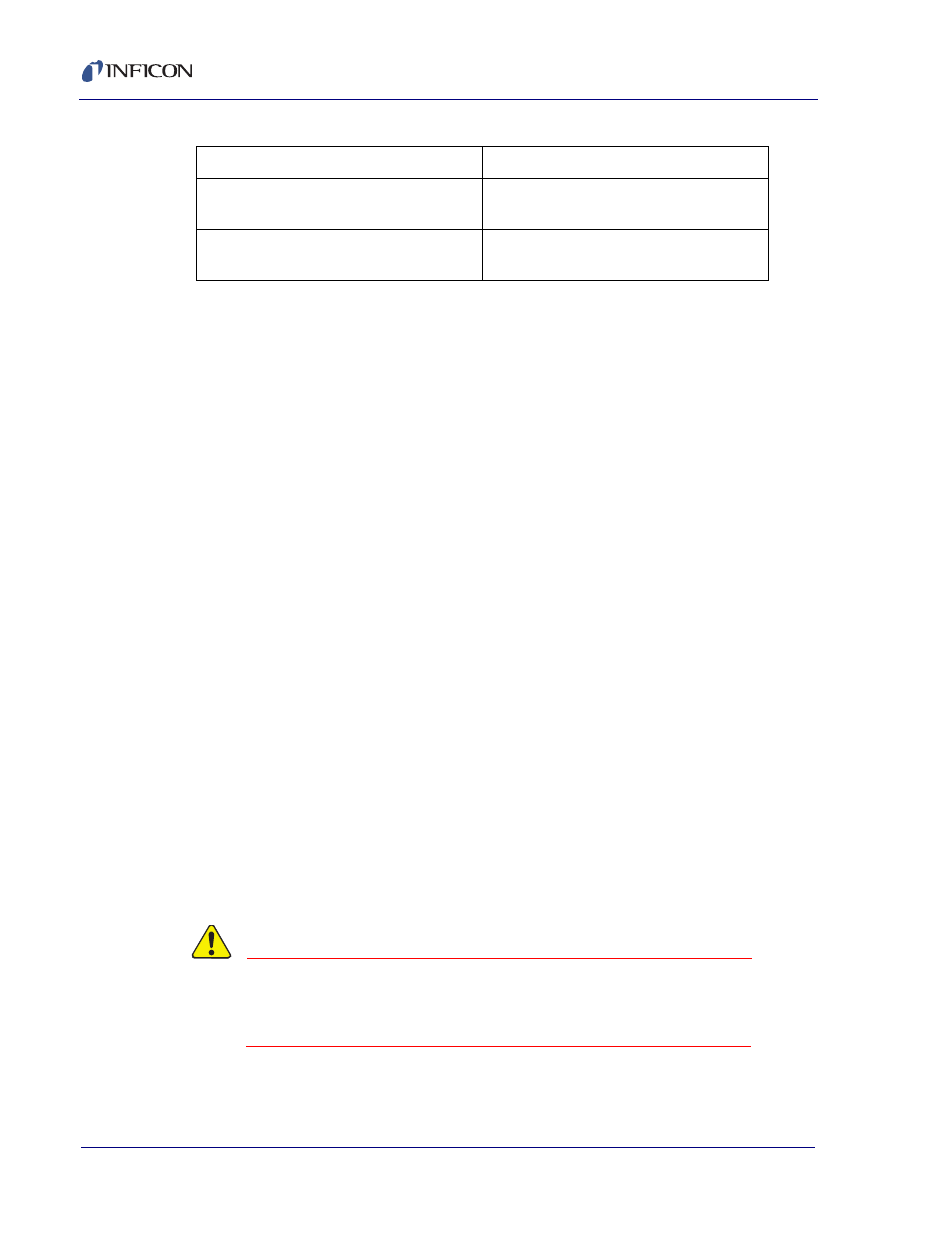

Water, air and coax length

Standard 30" (76 cm)

Crystal exchange

Front-loading, extraction tool required

(supplied with unit)

Mounting

Six #4-40 tapped holes on the back of the

sensor body

Table 1-1 Sensor specification (continued)