INFICON CrystalSix Sensor User Manual

Page 46

4 - 10

IP

N 07

4-

15

5L

CrystalSix Operating Manual

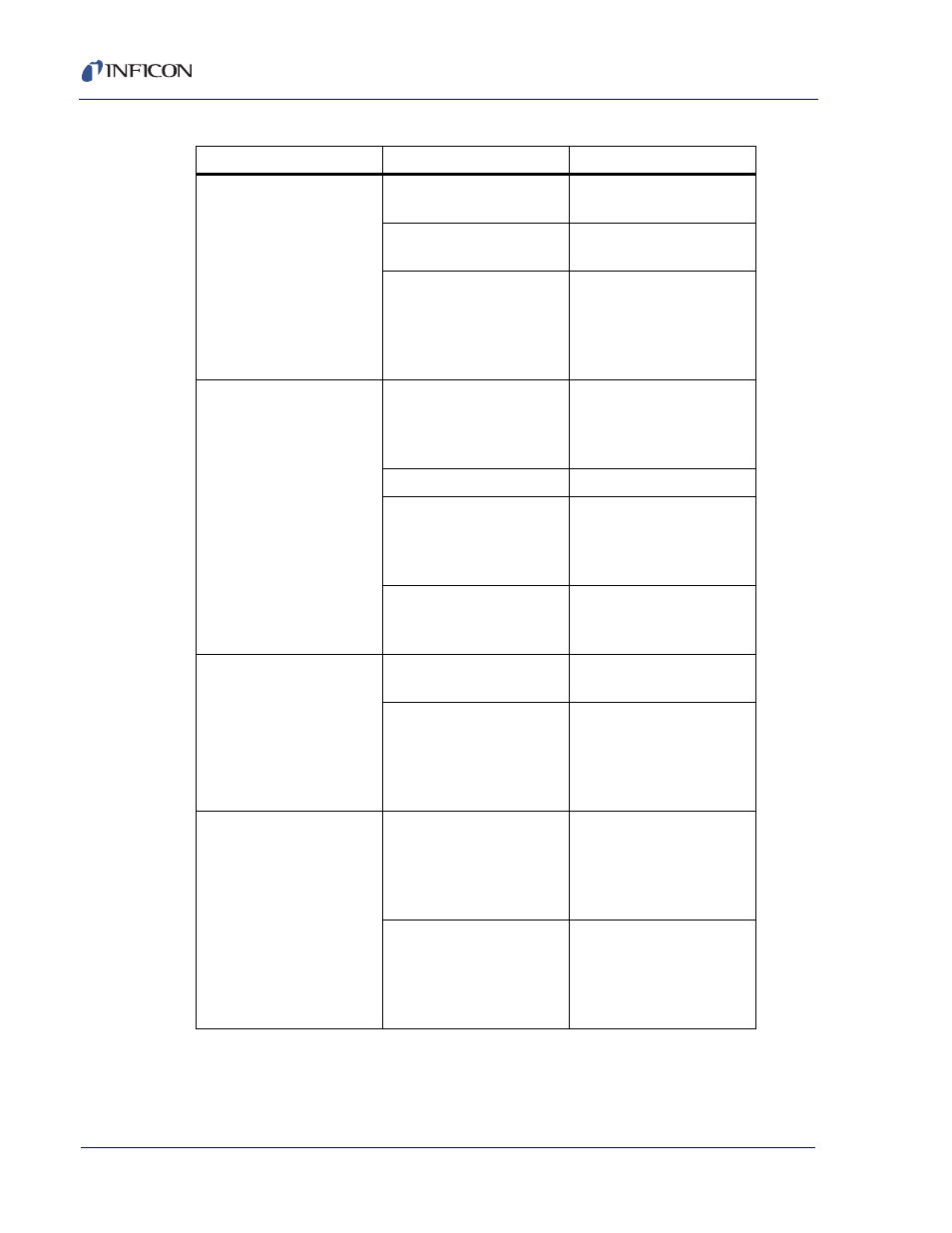

4. Large jumps of

thickness reading during

deposition

4a. Mode hopping due to

damaged crystal.

4a. Replace crystal.

4b. Crystal near the end of

its life.

4b. Replace crystal.

4c. Scratches or foreign

particles on the crystal

holder seating surface.

4c. Replace the crystal

holder (IPN 750-262-G1).

Clean, polish the crystal

seating surface of the

crystal holder.

5. Crystal ceases to

oscillate during deposition

before it reaches its

“normal life.

5a. Crystal is being hit by

small droplets of molten

material from the

evaporation source.

5a. Move the sensor

further away from the

evaporant source.

5b. Damaged crystal.

5b. Change crystal.

5c. Deposition material

built-up on edge of the

crystal holder and

touching the crystal.

5c. Clean the crystal

holder.

5d. Material on crystal

holder partially masking

full crystal area.

5d. Clean crystal holder.

6. Crystal does not

oscillate or oscillates

intermittently (both in

vacuum and in air).

6a. Defective or damaged

crystal.

6a. Replace crystal.

6b. Existence of electrical

short or poor electrical

contacts.

6b. Check for electrical

continuity and short in

sensor cable, connector,

contact springs,

feedthroughs.

7. Crystal oscillates in

vacuum but stops

oscillation after open to air.

7a. Crystal was near the

end of its life; opening to

air causes film oxidation,

which increases film

stress.

7a. Replace crystal

7b. Excessive moisture

accumulation on the

crystal.

7b. Turn off cooling water

to sensor before opening it

to air; flow hot water

through the sensor when

the chamber is open.

Table 4-1 Troubleshooting (continued)

Symptom

Cause

Remedy