6 gas evacuation, 7 tooling disconnection, 4 optimizing the test cycle – INFICON Sensistor ILS500F Leak Detection System User Manual

Page 46: Optimizing the test cycle, 6 gas evacuation 7.3.7 tooling disconnection

Recipes

46

ninp69e1-a (1410)

7.3.6

Gas Evacuation

7.3.7

Tooling Disconnection

Same function as Tooling Connection but in revers order.

For information about this step, see on page 40.

7.4

Optimizing the Test Cycle

Test Cycle can be divided in six main blocks:

1

Connection of Tested Object

2

Pre Evacuation of Residual Air

3

Filling with Tracer Gas

4

Tracer Gas Leak Test

5

Removal and Venting of Tracer Gas

6

Disconnection of Tested Object

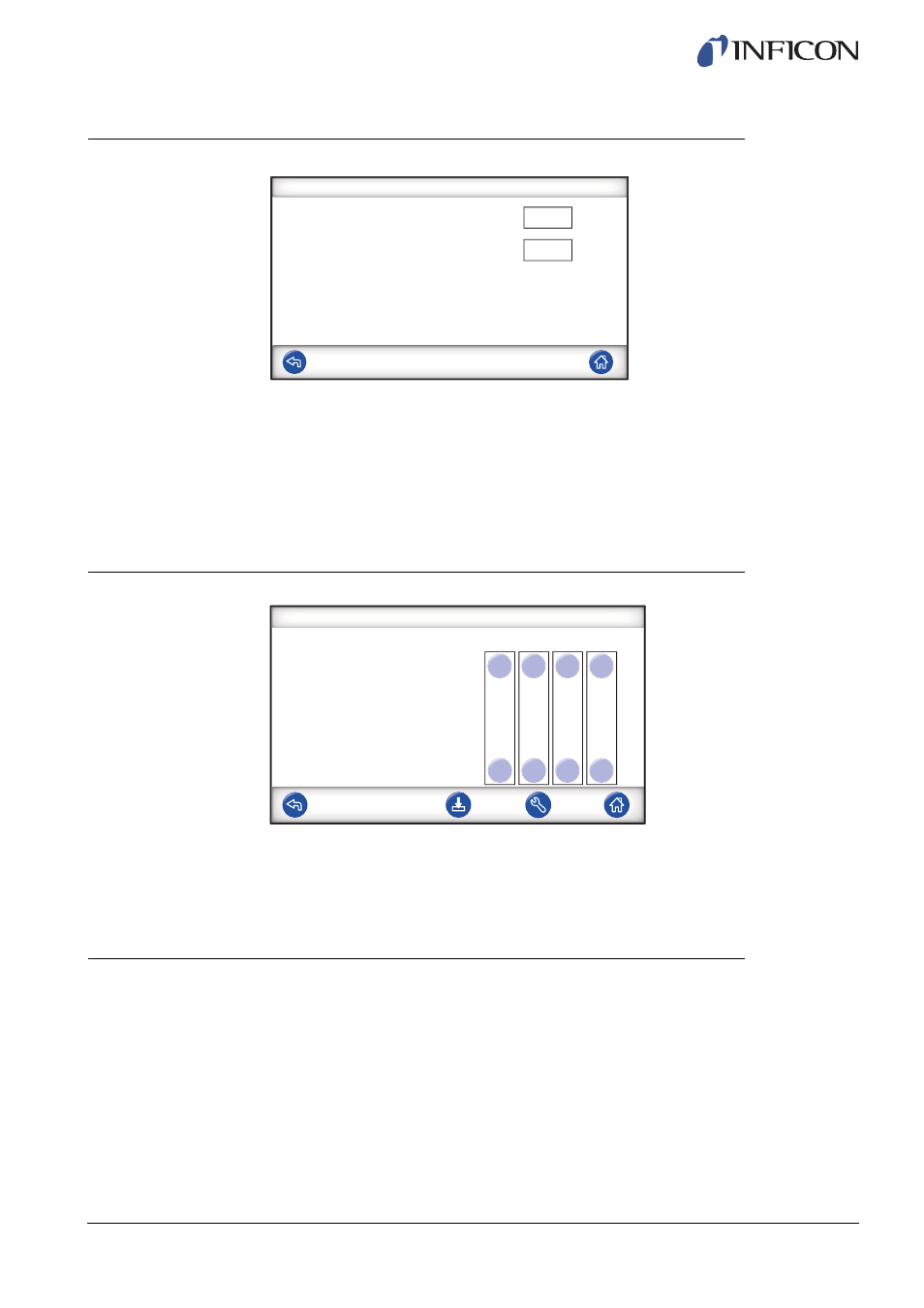

Gas Evacuation

Gas Evacuation Setpoint

Extended Gas Evacuation

-0,30

0,0

bar

s

Gas Evacuation Setpoint

Set desired level of Gas Evacuation.

-30 kPa (-0.3 bar, -4.4 psi) creates 30% vacuum,

which is adequate for most applications.

Extended Gas Evacuation

Extends time for gas evacuation, after Gas

Evacuation Setpoint has been reached.

Disconnection Sequence

Tooling Outputs

Test

Step

Step

Step

Stand-by

1

2

3

OFF

OFF

OFF

1

2

3

4