Medical compressed gas connectors, Troubleshooting – FasTest Compressed Gas Medical Connectors User Manual

Page 17

Medical Compressed Gas Connectors

FasTest, Inc. 1646 Terrace Drive Roseville, MN 55113 Support: (800) 444-2373 Fax: (651) 645-7390 www.fastestinc.com

15

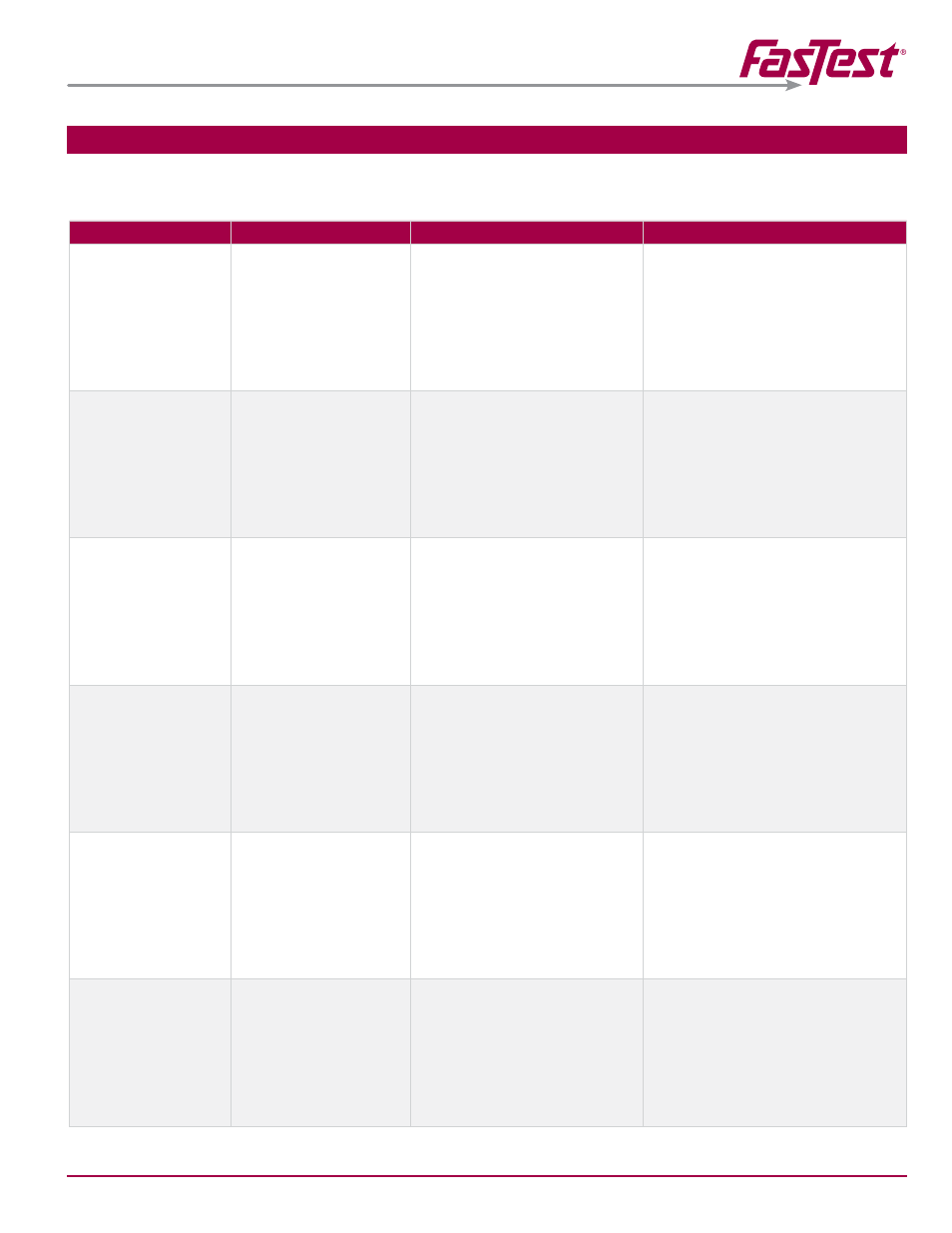

trouBlesHootIng

problem

recognized By

probable cause

recommended action

Short connection of

connector to valve.

Visual inspection of

connection joint.

Connector thread collets not

expanding properly during initial

hook-up to cylinder valve.

a) Visual inspection of valve. Replace

if damaged or worn.

b) Disconnect and reconnect

connector to valve. Be sure sleeve

is fully engaged. If problem is

unresolved, contact

FasTest.

Loose connection.

Connector is loose

despite proper

connection.

Worn or damaged threads of

cylinder valve.

Replace cylinder valve.

Improper operation.

Possible internal

leakage.

Visual inspection of

connector. Connector

difficult to operate.

Damaged, deformed or distorted

connector body, sleeve and

collet threads.

Remove connector from filling

operation immediately.

Return to

FasTest to determine

probable cause.

Gas leakage at

initiation of filling

cycle, leakage

decreasing as

pressure increases.

Continual sound of

escaping gas.

(a) Improper connection.

(b) Side load to filling connector

due to rigid supply line.

(a) Terminate filling cycle and repeat

connection.

(b) Replace supply line with swivel

and/or flexible pigtail.

Gas leakage

increases as

pressure increases.

Continual sound of

escaping gas.

Valve threads damaged.

Seat area of valve scored

or damaged.

Terminate filling cycle and replace

damaged or worn valve.

Gas leakage at

connection of

connector to valve.

Continual sound of

escaping gas.

(a) Damage or worn connector

sealing O-ring or damaged

cylinder valve.

(a) Visual inspection of connector

O-ring. Replace as required.

Recommend O-ring replacement

every 1000 cycles.

Medical and Industrial cga 540