Medical compressed gas connectors, Maintenance – FasTest Compressed Gas Medical Connectors User Manual

Page 14

FasTest, Inc. 1646 Terrace Drive Roseville, MN 55113 Support: (800) 444-2373 Fax: (651) 645-7390 www.fastestinc.com

12

Medical Compressed Gas Connectors

MaIntenance

Maintenance checklist

daily

Inspect for leak-tight seal

• The main seal must be replaced more frequently depending on wear. Dismantling of the connector

for this purpose is not required. It is recommended that an O-ring pick be used for removal to avoid

damage to the groove. Clean groove if required and insert new O-ring.

• Connection should operate smoothly. If the connector is forced, remove from service.

• Check for contamination, bent or missing components.

• Check for leaks.

Weekly

Inspect for correct function

• Inspect the correct engagement of the valve, collets or fittings.

• Check for any bent or missing components.

periodic

• Inspect that all threaded components are tight and properly torqued.

• Check for any bent or missing components.

• Check for proper actuation of handle, collets and all moving components.

• Check for leaks.

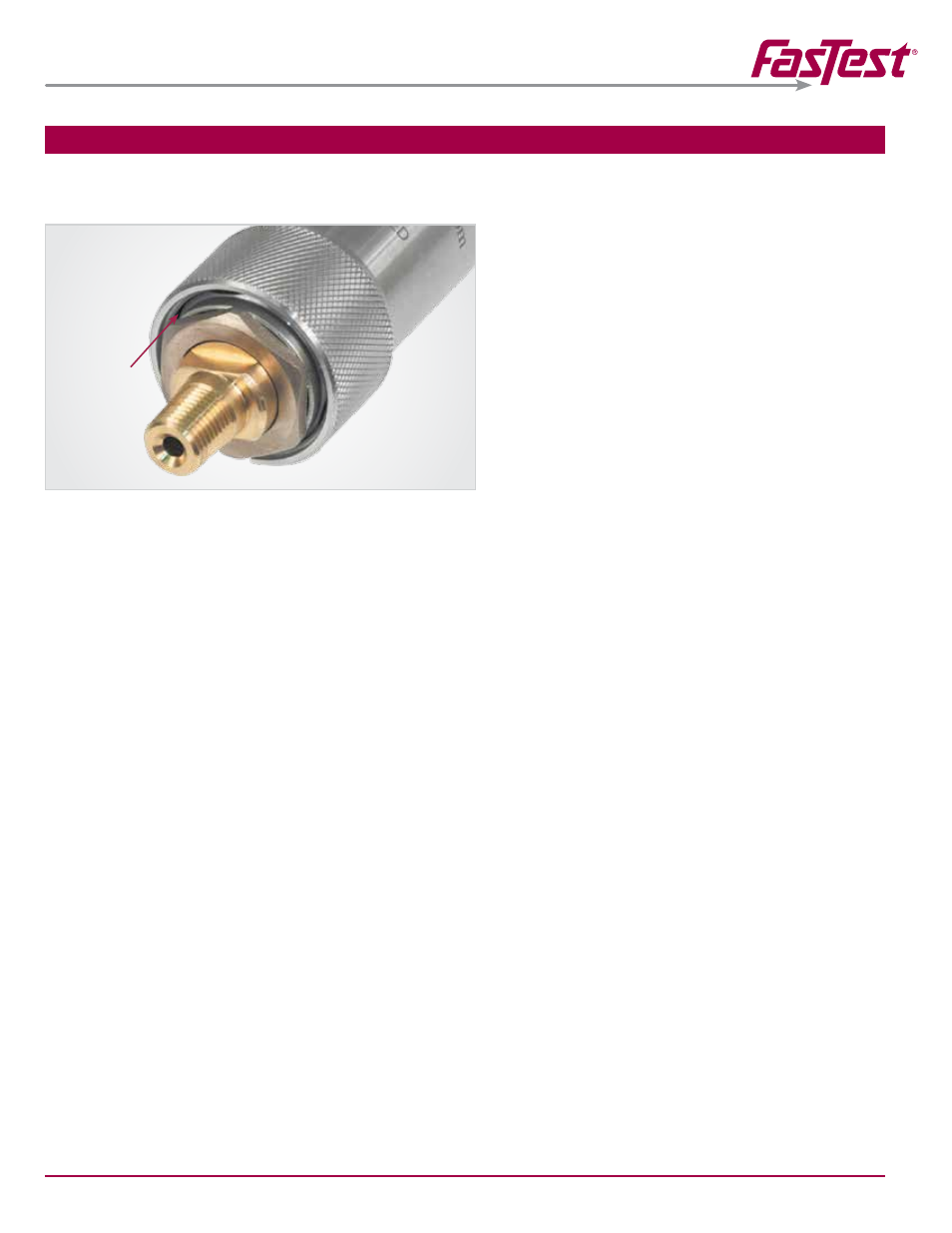

Medical and Industrial cga 540

Figure 29. Check retaining ring to make sure it is tightly

seated in its groove.

z

Check internal thread collets for a fixed-center position

and even spacing.

z

An “out-of-round” condition may hinder sleeve operation.

A visual inspection of the sleeve is usually sufficient.

Retaining

Ring