FasTest JXL Series User Manual

Operating instructions, Dimensional information: jxl external lever action, Collet set removal and installation

OPERATING INSTRUCTIONS

www.fastestinc.com

® Roseville, MN

Ph 1-800-444-2373

Fax 651-645-7390

WP013 04/2009

TEST PIECE

TEST PIECE

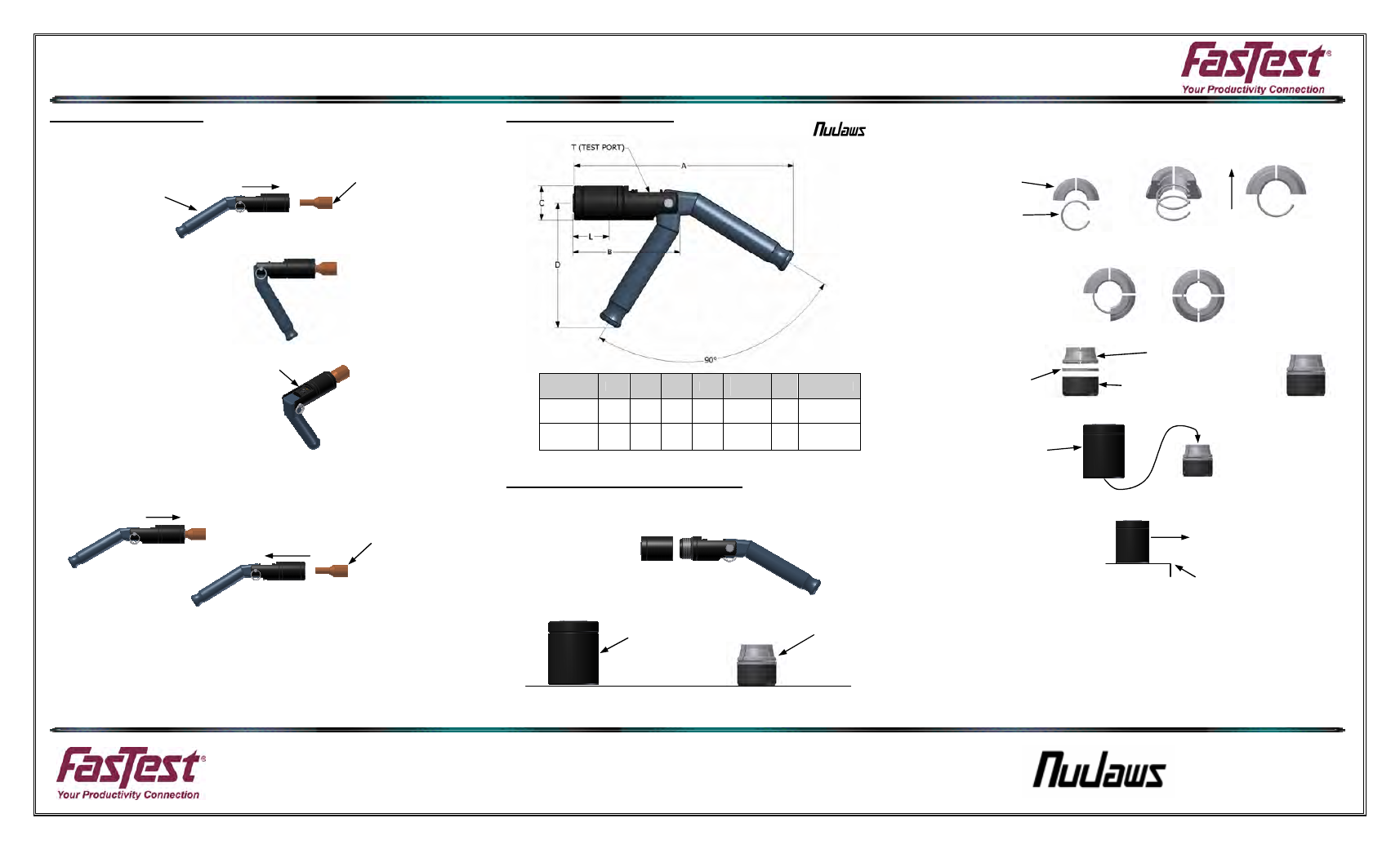

Operating Instructions:

Connecting Action:

1. Place lever in the in-line position then insert connector onto test piece. Make sure

test piece is inserted to the required minimum insertion length (see chart). This will

assure proper location relative to the main seal.

2. Rotate lever 90 degrees to the grip and seal position.

Note: Preferred position of lever

as shown with test media port on top.

3. Introduce test media through test port.

Disconnecting Action:

1. Vent test media pressure.

2. Rotate lever to the in-line position to release gripping action.

3. A slight forward motion of the connector toward the test piece opens the locking

collets.

4. Remove connector.

Note: The safety design of the pressure assisted gripping collets will not release

under pressure.

CAUTION: If excessive operating force or stickiness of the collet/seal assembly is

noted, remove collet/seal assembly (See Collet Set Removal and Installation:) and

check for alignment and lightly lube the bore of the housing with a petroleum jelly

or other compatible lubricant.

Dimensional Information:

JXL EXTERNAL LEVER ACTION

BODY SIZE

A

B

C

D

MAX

FLOW Ø

L

T

JXL0

7.25

3.65

1.12

4.13

.24

.79

1/8-27 NPTF

JXL1

7.25

3.58

1.62

4.22

.37

.85

1/4-18 NPTF

(L=Minimum Insertion Depth)

Collet Set Removal and Installation:

Collet Removal:

1. Place lever in the in-line position with housing (A) pointed downward, unscrew from

body (B). Use finger to keep main seal (F), washer (E) collets (D) and retaining rings

(C) inside housing (A).

2. Keeping all components inside housing

place housing on flat surface then lift housing off of internal components.

3. Collet Set components are now exposed for inspection or replacement.

Collet Installation:

1. First step, assemble collet segments (D) and retaining rings (C), form two pieces of

collets into a half circle and hold between thumb and middle finger. The raised

portion of the collets should be toward your thumb with the retaining ring groove

facing out.

2. Place the retaining rings (C) into the grooves in collets.

3. Add the last two pieces of collets to form a circle. Hold collet assembly together in

one hand.

4. Stack as shown. Set the collet assembly, largest side down, on the washer.

5. Place housing (A), threaded side first, over the completed collet assembly stack.

6. Slide the housing/collet assembly to the edge of the table and as you slide it off the

edge use your index finger to hold the seal/collet assembly in place inside housing.

7. Push on the seal, washer and collet assembly from the back to move it to the front

of the housing.

8. Turn housing over so that the threaded end is pointed up and screw connector body

onto housing. Tighten hand tight until the body o-ring (G) seals. The piston

assembly that contains the test port may also rotate. This can be realigned after the

housing is snug.

9. If collets are not aligned properly in the seal casing, the casing will not thread on

completely. When this occurs, loosen the housing and adjust the collet assembly,

you may have to start procedure again from step #1 above.

10. With collet in place and housing snugly tightened, rotate the lever to actuate

connector. Visually verify that the connectors gripping and sealing action is correct.

Continued on other side:

INSERT CONNECTOR

TEST MEDIA PORT

GRIP & SEAL

POSITION

CONNECT/

DISCONNECT

POSITION

ROTATE LEVER 90° FOR

GRIP AND SEAL ACTION

LEVER IN-LINE

POSITION

GRIP & SEAL

POSITION

REMOVE CONNECTOR

SLIGHT FORWARD MOTION

HOUSING (A)

COLLET SET

COMPONENTS

F, E, D & C

HALF CIRCLE

FINGER SIDE

RINGS INTO

GROOVES

MAIN SEAL (F)

BEVEL SIDE DOWN

WASHER (E)

COLLET SEGMENTS (D)

AND RETAINING RINGS (C)

SLIDE

FINGER/TABLE EDGE

(D)

(C)

(A)