FasTest FI Series User Manual

Operating instructions

FasTest Inc. 1646 Terrace Drive Roseville, MN 55113 Phone: 651-645-6266 Toll Free: 800-444-2373 www.fastestinc.com

Operating Instructions

Note: A tapered washer with a counterbore is used on all FI01, FI1,

FI2, FI3 and FI4 connectors. The retaining ring will be recessed in

the washer’s counterbore when the connector is pressurized

Operating Instructions for FI and FIxM (Metric Termination)

Internal Pneumatic Operated Connector.

FI connectors provide fast, leak-free connections for pressure and vacuum

testing, fluid filling and flushing. The connectors are activated by

compressed regulated air acting on a piston which expands an

elastomeric seal to form a leak-tight connection. Testing, filling or flushing

of the piece is accomplished by introducing liquid or gas media through

the FasTest FI connector.

The use of pressurized media for sealing, testing and filling requires a

thorough understanding of the FasTest FI Installation and Operating

Instructions.

Do not operate FasTest connectors without completely reading and

understanding the following Installation and Operating Instructions.

Read and understand each of the following six steps

before operating the connector.

A. Installation of seals.

B. Extended shaft, stroke limit

C. Tapered front washer feature

D. Mounting the connector.

E. Attachment of pilot pressure and test media supply

lines.

F. Connector operation instructions.

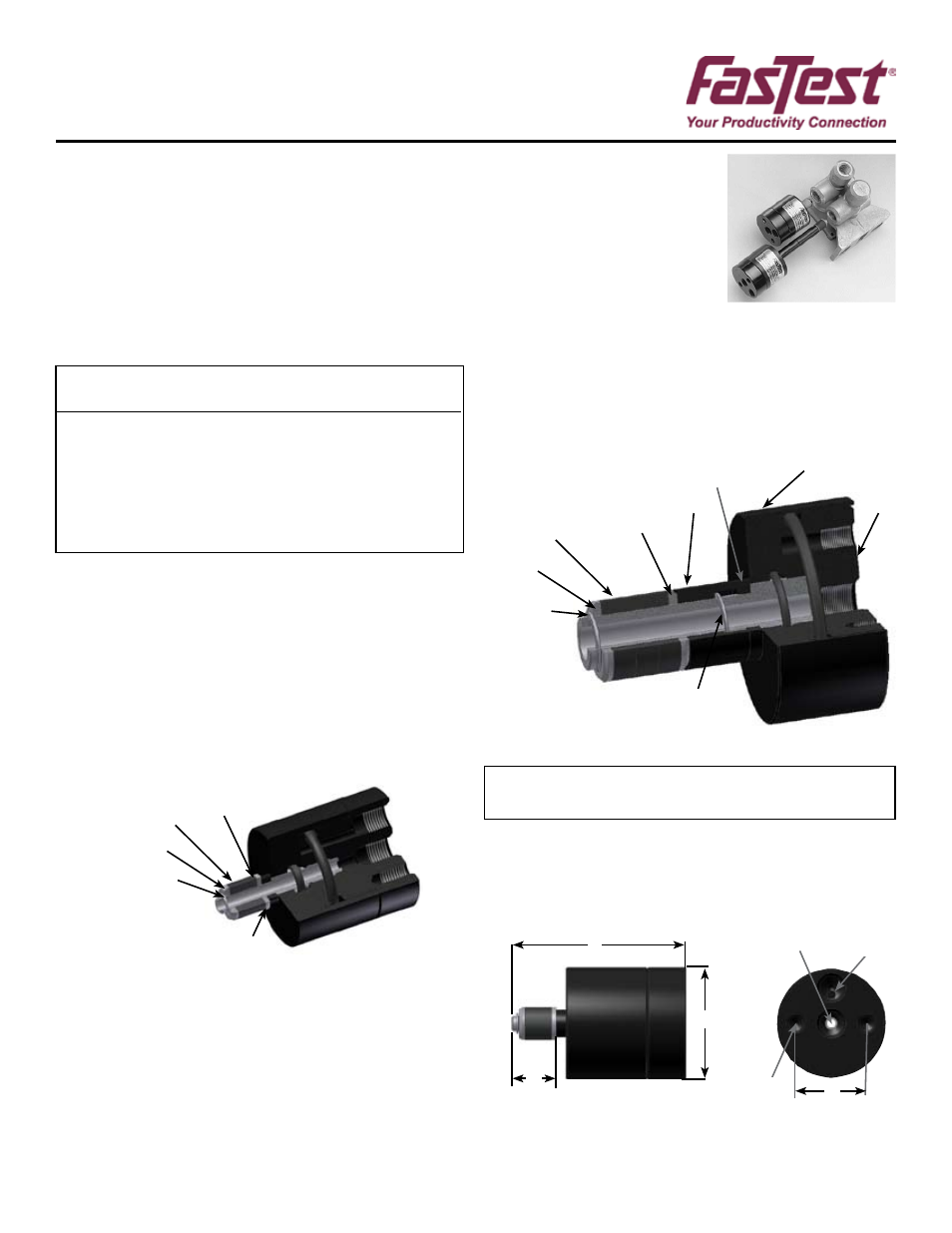

A: Installation of Seals

1. For seal replacement, remove retaining ring from shaft tip and slide off

old seal set and washers. Spacer piece is to remain on connector shaft.

2. Seal Set contains elastomer seals, washers and retaining ring. For

complete listing of seal set size ranges see Chart 2.

3. Verify that seals and washers are the same size (outside diameter).

4. Assemble seal set onto shaft per Diagram 1.

5. Attach new retaining ring to groove in shaft tip. Flat side of retaining ring

must face away from washer.

6. A tapered washer with a counterbore is used at the shaft end on

all FI01, FI1, FI2, FI3 and FI4 connectors. The retaining ring will be

contained within the counterbore when pilot pressure is delivered to the

connector

CAUTION:

1) Periodically inspect connector, seals and washers for wear or

damage. Replace worn or damaged connector seal sets to prevent

loss of sealability and personal injury.

2) If replacing seals only, inspect washers for warping, corrosion, or

excessive wear.

3) Replace complete FasTest main seal set if washers are

warped, corroded or worn.

4) Always replace retaining ring when changing the main seal.

B: Extended Shafts:

Connectors with extended shafts are

designed for sealing remote ports or for

applications requiring connectors to be

offset rather than side-by-side mounted

which may be required when multiple test

ports have close center-to-center distances.

Stroke Limiters:

FI connectors that have shaft extensions of at least one inch (1”) beyond

the standard for any model FI connector will be assembled with a stroke

limiter. This feature will prevent over pressurization and excessive travel

of the FI seals when pilot pressure is applied to an FI not placed in a test

piece.

Additionally, if an FI stroke limiter prevents sufficient pressurization for

a sealing or testing application, it may be removed very easily without

reducing the effectiveness of the connector.

C: Dimensions

Retaining Ring

Flat Washer

Seal(s)

Flat Washer

Stroke Limiter

Standard on 1” or longer extended FI shafts

Spacer, Extended

Spacer,

Nominal

Housing

Piston

Spacer

Retaining Ring

Tapered Washer

Flat Washer

Seal(s)

Diagram 1:

FI1 with Seal Set

Diagram 2:

FI5 1” extended shaft and standard seal set

Maximum Test Pressure: 120 psi

Vacuum Rating: 10-8 torr

A

F

K

D

E

C

Test

Port

Mounting

Holes

Pilot

Port

Diagram 3: Connector Features

L

WP008 1/2009 rev. C