FasTest ML Series User Manual

Operating instructions, Mounting of connector, Me/ml connector dimensions

OPERATING INSTRUCTIONS

www.fastestinc.com

Roseville, MN

Ph 1-800-444-2373

Fax 651-645-7390

WP090 9/30/2010

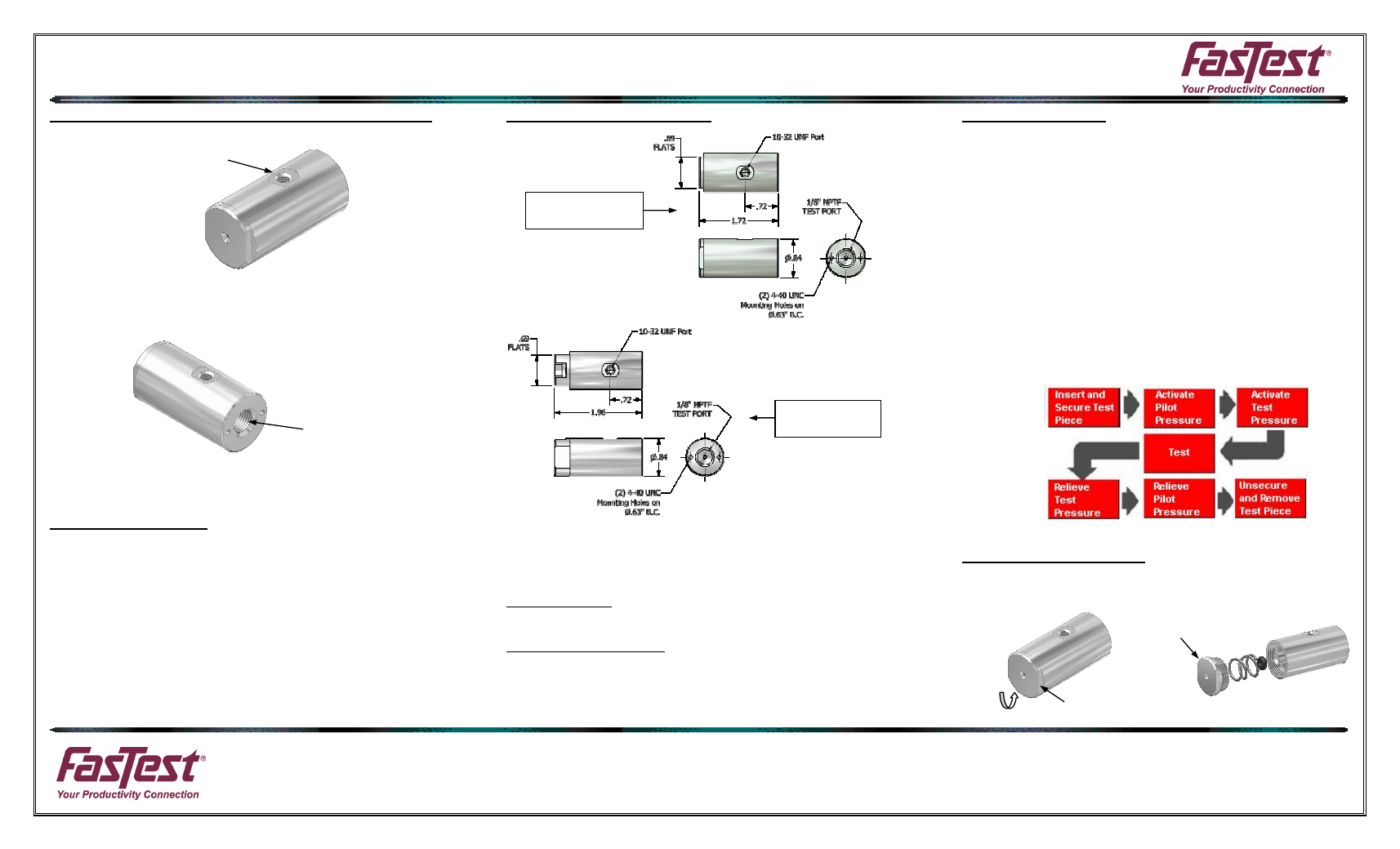

ME001

CONNECTOR

ML001

CONNECTOR

Attachment of Pilot Pressure and Test Media Supply Line:

1. Attach pilot pressure air line to pilot port.

2.

A pneumatic regulated source is required to maximize seal life and assure

optimum seal ability for the application. The pilot pressure should be minimized to

maintain sealing on the test piece without excessive compression of the seal.

3. Attach test media line to the test port.

4. Provide a means whereby test pressure will not be introduced until the pilot

pressure required to seal is reached. The means should also provide quick exhaust

of test pressure in the event pilot pressure falls below the minimum required to seal.

Mounting of Connector:

The ME Connector must be SECURED to the test piece by a mechanical device

before proceeding.

• The test connector must be secured with a mechanical or other device to assure the

connector is not uncoupled from the test piece. The test itself will provide an un-

coupling force. The securing or holding device may be a fixture, clamp, cylinder or

other appropriate means that prevents ejection of the test piece from the connector.

Uncoupling force example:

If the test piece has a ½” O.D. and is tested at 400 psi maximum. The uncoupling force = area(πr²) x

pressure) = π x .25² x 400 = 79 lbs.

• Secured device should be designed to withstand this force and include an adequate margin for

safety.

• Do not activate the connector without an adequate and safe securing mechanism.

• Mount the FasTest ME connector to the fixture or appropriate device using either threaded

mounting holes on the rear of the connector body, (“G” Diagram 2), or appropriate adapter.

ME/ML Connector Dimensions:

Maximum test pressure: Vacuum to 500 psi

Material Specifications

Body, Housing, Piston:

Aluminum

Standard Main Seal:

FDA approved Viton

Standard O-Rings:

FDA approved Viton

Other materials available on request.

NOTE: All specifications subject to change without notice.

Connector Operation:

1.

Insert test piece into the end of the connector and secure.

Make sure the test piece is inserted to the required minimum insertion

length. This will assure proper location relative to the seal. Make sure

the connector and test piece are secure

2.

Apply pilot pressure to seal against the part.

Generally, a 60 to 90 psi pneumatic pilot pressure source is required.

Additional pilot pressure may be required for contoured surfaces (i.e.,

threads etc…). See FasTest catalog for Pilot Pressure Booster.

CAUTION: Do not activate PILOT or TEST PRESSURE without test

piece in place.

3.

With pilot activated, introduce gas or liquid through the FasTest ME

connector until desired testing, filling or flushing is complete.

Provide a means whereby test pressure will not be introduced until the

pilot pressure required to seal is reached. The means should also

provide quick exhaust of test pressure in the event pilot pressure falls

below the minimum required to seal.

4.

Perform testing operation.

5.

Relieve test pressure.

6.

Relieve pilot pressure.

7.

Remove test piece.

Installation of Seals ME001:

To Replace Seal

1. Unscrew and remove seal casing. Wrench flats provide for easy removal.

NOTE: The internal spring is set loose inside the housing. Make sure that this spring is

not damaged or lost.

PILOT PORT

ME & ML

TEST MEDIA PORT

ME & ML

ccw

WRENCH

FLATS

SEAL

CASING