Bail handle compressed gas connectors, Maintenance – FasTest Bail Handle Gas Connectors User Manual

Page 8

FasTest, Inc. 1646 Terrace Drive Roseville, MN 55113 Support: (800) 444-2373 Fax: (651) 645-7390 www.fastestinc.com

6

Bail Handle Compressed Gas Connectors

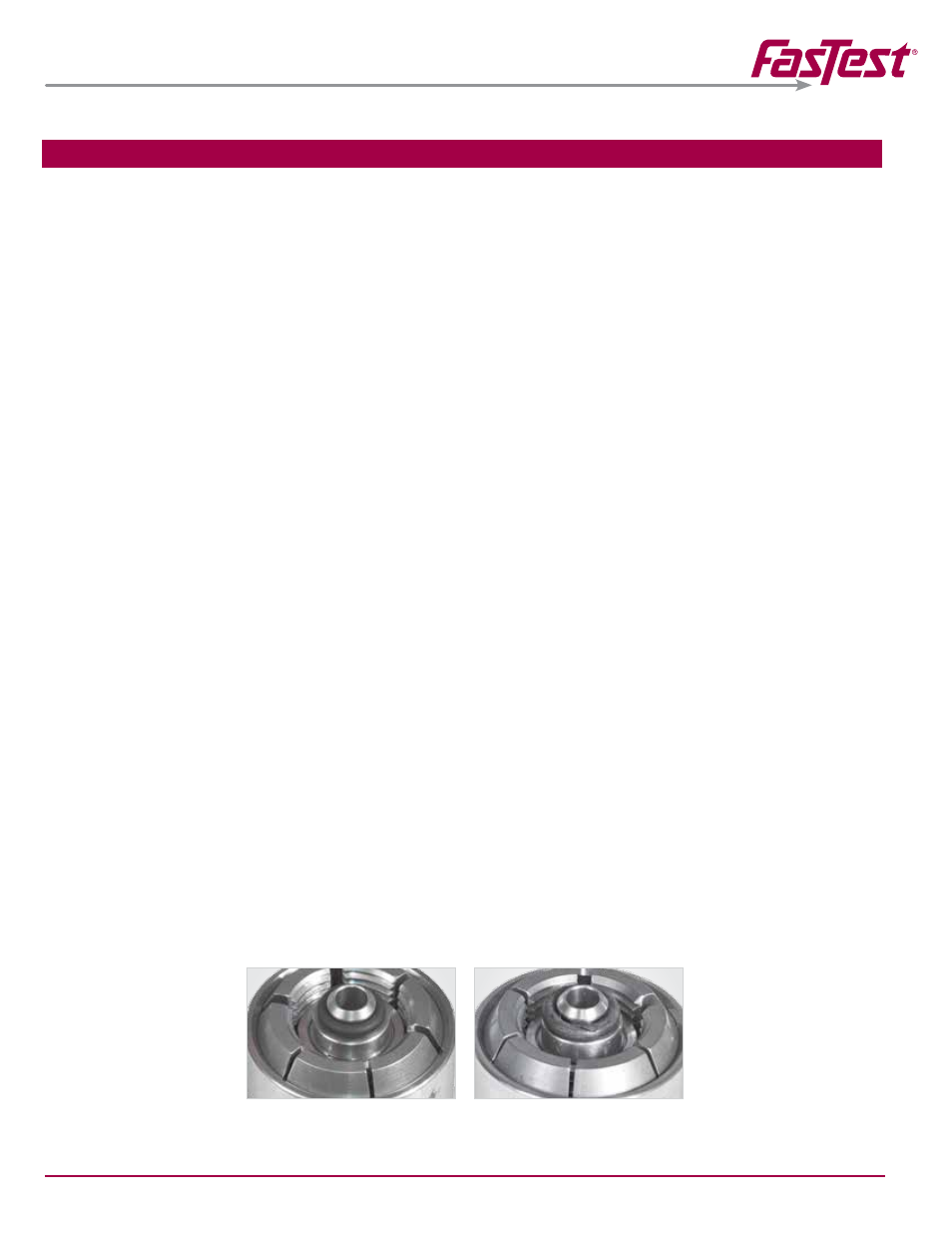

Main seal

The main O-ring seal must be replaced at least every 1000 cycles.

FasTest recommends a daily visual

inspection of the sealing O-ring, located at the tip of the filling nozzle. Inspect for tears or cracks in the

O-ring surface. Replace O-ring if tears or cracks are visible or verified. Some applications require more

frequent seal changes.

MaIntenance

good Maintenance practices

• CGA standards for medical oxygen filling, CGA 870 and CGA 346/540 series connectors may require

periodic lubrication. Use Krytox or approved equivalent only.

• Maintain accurate and complete product maintenance records.

• In addition to these suggested maintenance guidelines, your companies overall safety and maintenance

requirements should be applied to

FasTest gas connector products.

• It is recommended that gas connector products involved in high-volume filling be returned to

FasTest for

a complete product inspection and required maintenance every 5 years.

• Adhering to a consistent product maintenance program will minimize product returns for inspection as

well as required maintenance costs.

• Minimize the use of soap solutions sprayed directly onto connector. These types of solutions cause

a build-up that can hamper proper connector operation. Also, avoid contacting connector with any

petroleum base chemicals that can cause product contamination.

• DO nOT EXCEED THE MAXIMuM OPERATInG PRESSuRE AS STATED In BOTH PRODuCT

LITERATuRE AnD On ALL InDIVIDuAL COnnECTOR PRODuCTS SOLD BY FASTEST.

connector Maintenance

The following maintenance guidelines apply to all

FasTest gas connector products. Additional guidelines that

apply only to a specific CGA standard connector are noted.

• A daily, weekly and periodic inspection of the connector by a competent person is recommended.

Inspection should include wear of swivel joints, damage to the body, leak-tightness, ease of operation,

sufficient lubrication, wear, dirt accumulation and damage. (See Maintenance Checklist)

• If upon inspection a problem is noted, refer to the Troubleshooting Guide at the end of this manual.

DO nOT DISMAnTLE THE COnnECTOR.

• The manufacturer (

FasTest) should refurbish connectors after 50,000 fill cycles.

• You may use only original

FasTest spare parts that are designed for the application and are subject to

strict quality control. See Warranty.

Figure 11. An example of a

good O-ring main seal

Figure 12. An example of a

bad O-ring main seal