Bail handle compressed gas connectors, Troubleshooting – FasTest Bail Handle Gas Connectors User Manual

Page 12

FasTest, Inc. 1646 Terrace Drive Roseville, MN 55113 Support: (800) 444-2373 Fax: (651) 645-7390 www.fastestinc.com

10

Bail Handle Compressed Gas Connectors

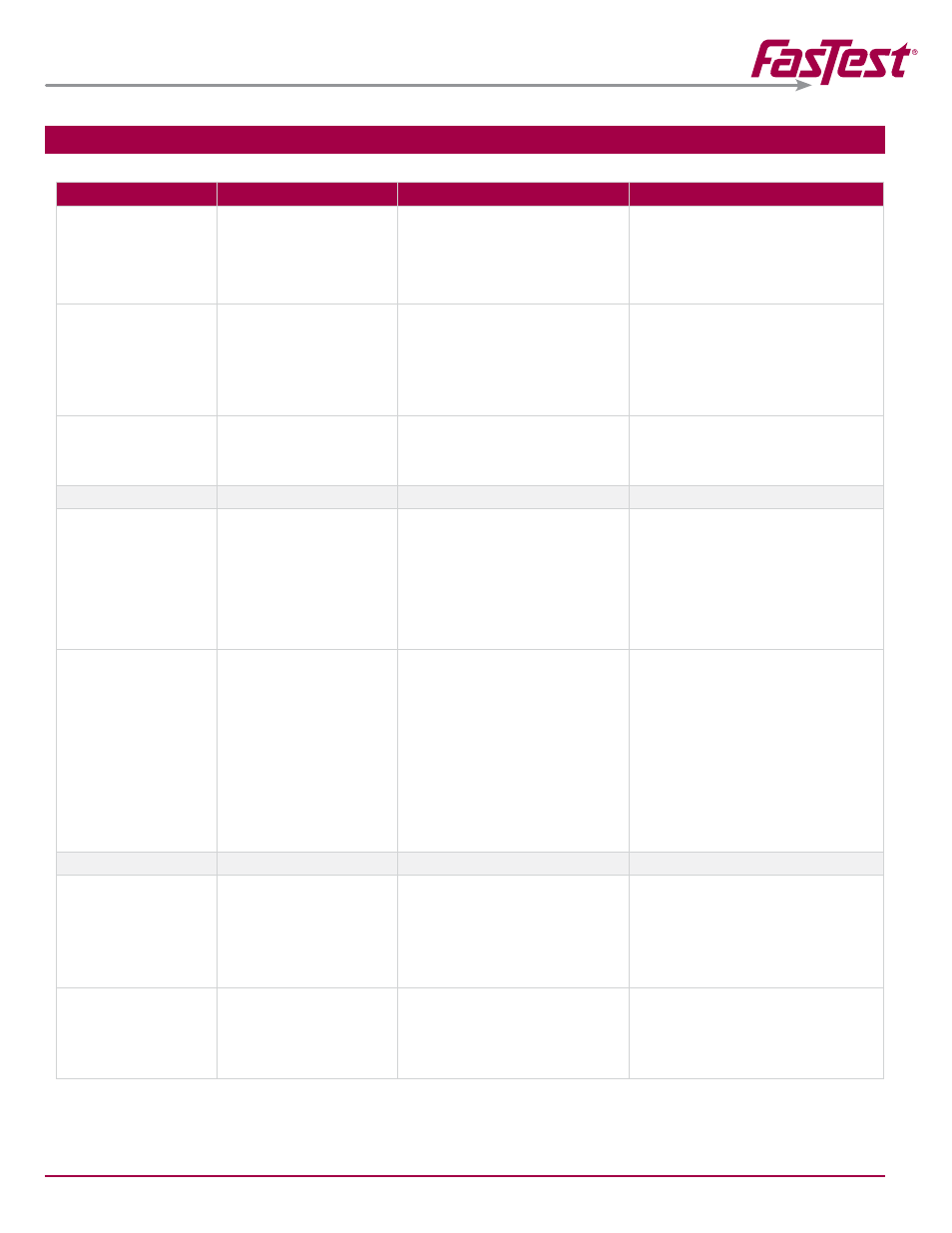

trouBlesHootIng

problem

recognized By

probable cause

recommended action

Gas leakage at

connection of

connector to valve

Continual sound of

escaping gas

Damaged or worn connector

sealing O-ring or damaged

cylinder valve

Visual inspection of connector

O-ring. Replace as required.

Recommended O-ring replacement

every 1000 filling cycles

Gas leakage at

initiation of filling

cycle, leakage

decreasing as

pressure increases

Sound of escaping gas

(a) Improper connection

(b) Side load to filling connector

due to rigid supply line

(a) Terminate filling cycle and

repeat connection

(b) Replace supply line with swivel

and/or flexible pigtail

Gas leakage

increases as

pressure increases

Sound of escaping gas

Blow off

Valve threads damaged

Seat area of valve scored or

damaged

Terminate filling cycle and replace

damaged or worn valve

Safety pin does not

activate during

filling cycle

Safety pin at rear of

connector not extended

outward from connector

body

(a) Damaged or bent pin

(b) Lack of lubrication and/or dirt

contamination

(a) Field replacement of actuator

pin assembly

(b) Remove safety pin assembly,

clean and lubricate with

approved lubricant

Safety pin does

not retract upon

completion of

filling cycle

unable to remove

connector

(a) Damaged or bent pin

(b) Lack of lubrication and/or dirt

contamination

(c) System under pressure

(a) Field replacement of actuator

pin assembly

(b) Remove safety pin assembly,

clean and lubricate with

approved lubricant

(c) Vent or exhaust system of gas

before attempting disconnection

Actuator handle

loose

Excessive handle

movement from

side-to-side when

connected to valve

Loose or missing actuator

handle screws

Replace missing screw or remove

existing screw. Apply thread lock to

screw threads. Reinsert and tighten

to 8-10 ft-lbs.

Do not over tighten screw

Inability to fully

engage actuator

handle

Visually inspect

connection with valve to

determine if connector

threads are exposed

Short connection to cylinder

valve

Disconnect and reconnect to

valve with connector fully seated

into valve

Gas Connector CGA standards 346, 540, 580 and 580 RPV series. Gas connector products should be visibly inspected

on a routine basis to ensure efficient product performance. Refer to the Maintenance Checklist on page 8.