Securing the isolated downconductor – ERICO ISODC Isolated Downconductor System User Manual

Page 13

13

www.erico.com

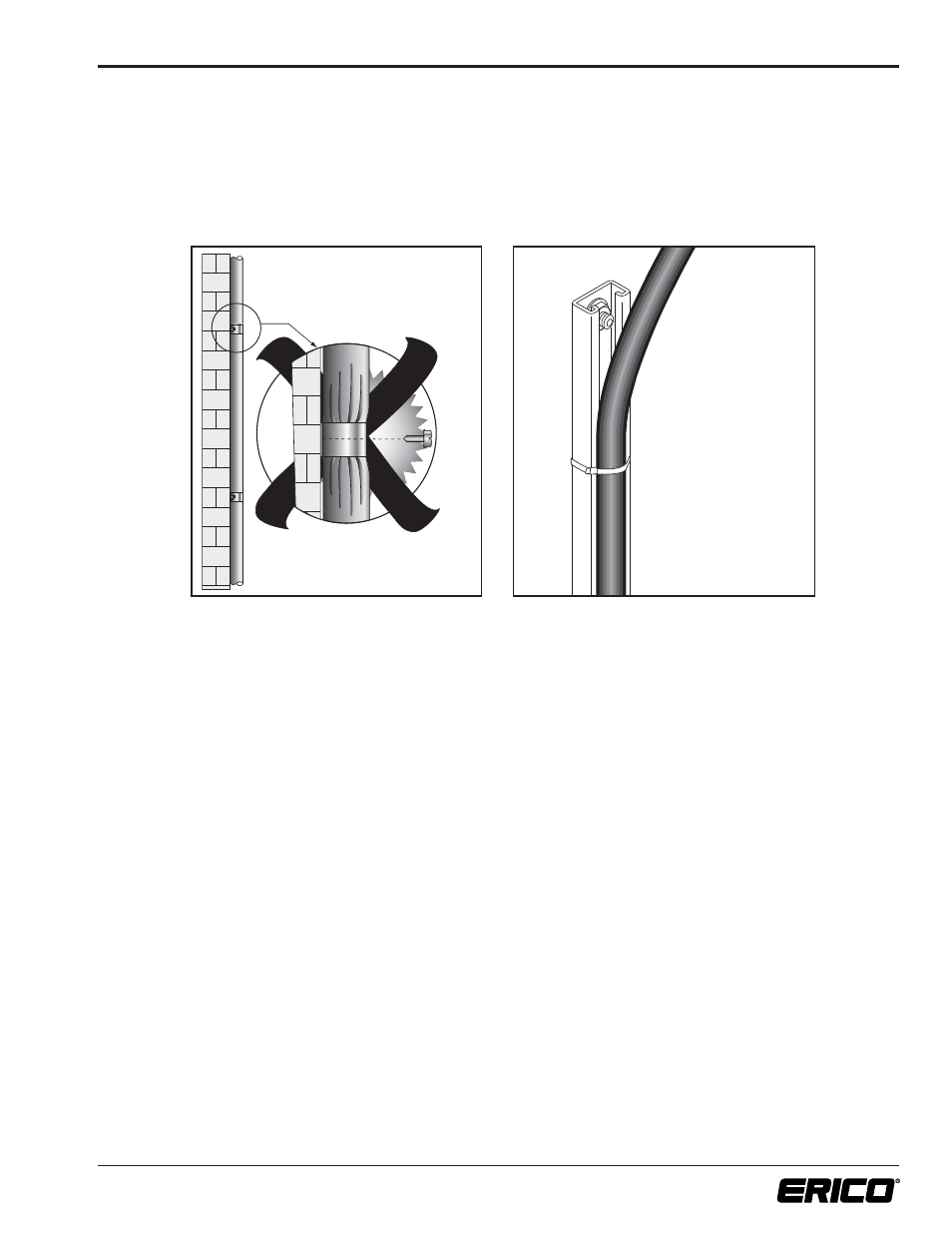

• It is not possible to join the Isolated Downconductor, so before installing, ensure sufficient length is available to route the Isolated

Downconductor using the most direct route possible with minimum of bends (do not exceed minimum bending radii specification of 450 mm).

• Fix the Isolated Downconductor to the structure using metallic fixings – these provide mechanical and electrostatic connection of the Isolated

Downconductor sheath to the structure. Do not use insulated fixings.

• Do not damage the Isolated Downconductor by over tightening straps or using non ERICO

®

approved fasteners

.

Use ERITECH

®

clamps only

CABTIESS can be used

to maximum diameter

of 150 mm

DO NOT use

FIXOBAND or similar

Figure 8. Isolated Downconductor fixing examples.

• Do not install the Isolated Downconductor within metallic or insulated pipes.

• Secure the Isolated Downconductor at 1 m intervals.

• Only cut the lower Isolated Downconductor section to length once Isolated Downconductor is fixed in position and required length

is confirmed.

• The black sheath of the Isolated Downconductor must not be damaged. The sheath is fragile and care must be exercised in handling and

installation. It should not be installed in water or ground.

5. SECURING THE ISOLATED DOWNCONDUCTOR