Cadweld, Mold inspection – ERICO CADWELD Electrical Connections User Manual

Page 9

9

www.erico.com

A CADWELD

®

mold is designed to last for an

average of 50 connections. This will vary according

to the care given the mold during use.

Inspect the mold regularly. Check the

following items to determine if a mold should

be replaced:

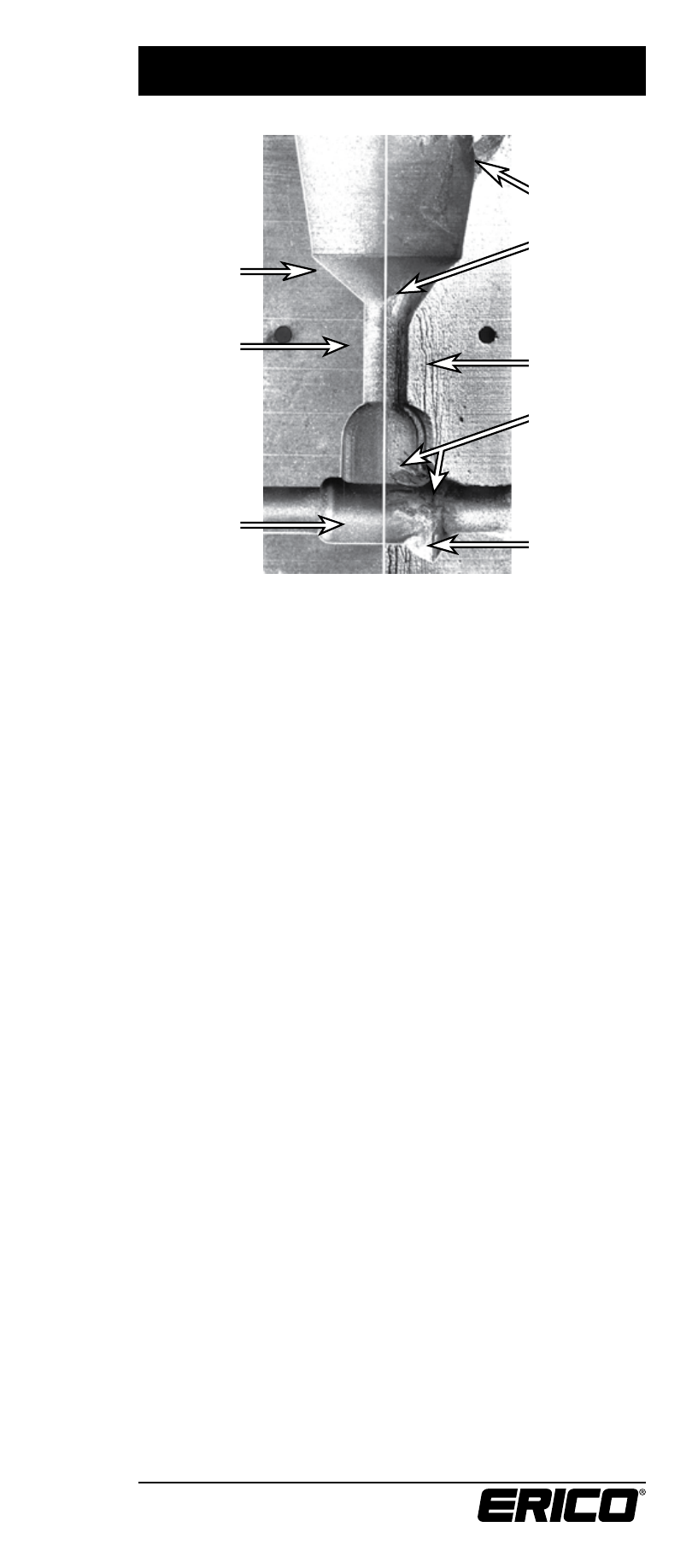

Cable Opening

• The conductor should fit snugly. A loose fit will

cause leakage.

• The opening should not be chipped or worn

Weld Cavity

• The cavity should be well defined.

• There should be no chips or gouges.

Tap Hole

• The tap hole should be well defined.

Disk Seat

• The seat should not be worn or chipped;

the disk must seat properly.

Mold Parting Face

• The parting face should not be chipped.

• The parting face should always be cleaned

properly. Use a clean shop towel or newspaper

and wipe clean. Using a wire brush to clean

the mold will cause erosion and quickly

destroy the mold.

CADWELD

®

Mold Inspection

Replace

Weld

cavity well

defined

Good

Mold

parting face

smooth

Mold parting

face has

erosion lines

Chip in mold

parting face

Disk seat worn

Tap hole

well

defined

Cable opening

worn

Chip in weld

cavity

- 6Z34VF14 Rod Hanging Basket Tray Clip (1 page)

- 766PM Far Side Box Support (1 page)

- 766PMD Far Side Box Support (1 page)

- CADDY MPVTI Low Voltage Mounting Clip (2 pages)

- H-Series CADDY PYRAMID Support System (3 pages)

- CADDY PYRAMID RL, PIPE RETAINERS (2 pages)

- CADDY PYRAMID Rooftop Equipment Support (4 pages)

- CADDY PYRAMID Single Post Support (1 page)

- CADDY PYRAMID TF Series, Fixed Height Tool-Free Supports (2 pages)

- CADDY ROD LOCK Anchor Screw (2 pages)

- CADDY ROD LOCK Beam Clamp (2 pages)

- CADDY ROD LOCK Channel Nut (2 pages)

- CADDY ROD LOCK L-Bracket (2 pages)

- CADDY ROD LOCK Strut (2 pages)

- CADDY SPEED LINK Riveted Accessories (4 pages)

- CADDY SPEED LINK SLK-Keyless Locking Device and Bulk Cable (2 pages)

- CADDY SPEED LINK SLK-Keyless Locking Devices (2 pages)

- CADDY SPEED LINK-Accessory Cables (1 page)

- CADDY SPEED LINK-SLK Cable End Accessories (4 pages)

- TSGB Series Screw Gun Bracket (2 pages)

- GLIDER Electrical Box Attachment (2 pages)

- H Series-Electrical Box Bracket (2 pages)

- ROD LOCK Plywood Pre-set Anchor (2 pages)

- ROD LOCK Strut End Bracket (2 pages)

- ROD LOCK Strut (2 pages)

- CADDY ROD LOCK Strut Nut (2 pages)

- CER4 Cable from Stud (2 pages)

- High Performance CADDY CAT HP J-Hook Assemblies (6 pages)

- KBT Wire Basket Tray Clip (1 page)

- MPCB1220 (2 pages)

- SBC Series, Beam Clamp, 3/8" and M10 (1 page)

- TSR200 Telescoping Strut Replacement Bracket (2 pages)

- TSRBS1625 Telescoping Box (3 pages)

- Universal Pedestal Clamp (2 pages)

- Branch Line Restraint Device (2 pages)

- Branch Line Restraint Strucural Attachment Fitting for Steel 12 gauge (2 pages)

- Branch Line Restraint, Structural Attachment Fitting for Concrete or Wood (2 pages)

- Branch Line Restraint, Structural Attachment Fitting with 3/8"-16 male thread" (2 pages)

- 510 CADDY EZ RISER (2 pages)

- 429 CADDY MACROFIX PLUS NI (1 page)

- Seismic Hanger Clamps (3 pages)

- CADDY PYRAMID Equipment Supports (3 pages)

- CADDY ROD LOCK Bottom-Mount Duct Bracket (2 pages)

- Bottom-Mount Duct Bracket, Narrow (2 pages)

- Top-Mount Duct Bracket (2 pages)