The cadweld, Process – ERICO CADWELD Electrical Connections User Manual

Page 4

4

www.erico.com

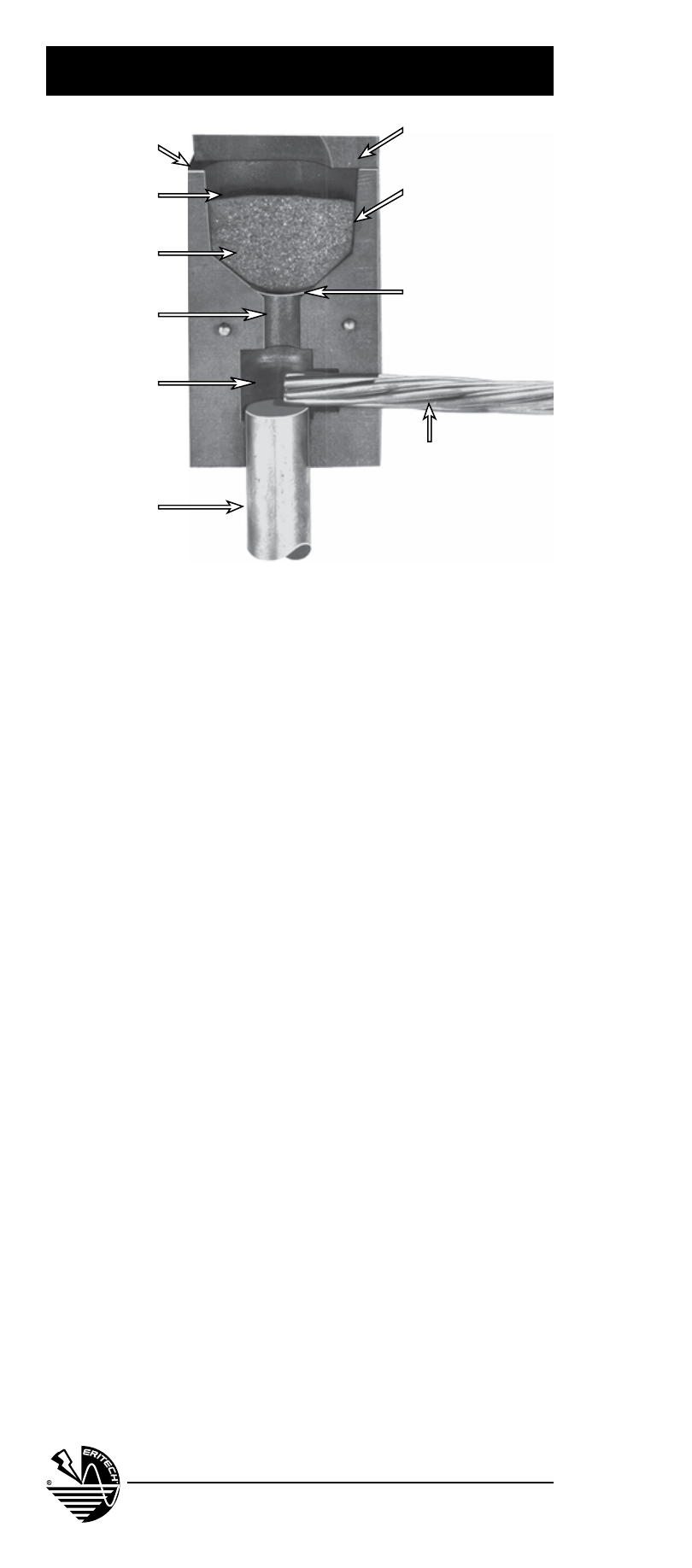

The CADWELD

®

process is a method of making

electrical connections of copper to copper or

copper to steel in which no outside source of

heat or power is required.

In this process, granular metals (granular copper

oxide and aluminum) are dumped from a container

into a graphite crucible and ignited.

The reduction of the copper oxide by the aluminum

(exothermic reaction) produces molten copper and

aluminum oxide slag. The slag floats to the surface

and the disk melts, allowing molten copper to flow

into the weld cavity and complete the weld. The

weld is allowed to solidify. The mold is removed

and made ready for the next weld. The process

takes seconds to complete.

BEFORE WELDING: READ, UNDERSTAND

AND FOLLOW ALL SAFETY INSTRUCTIONS

PACKAGED WITH YOUR MOLD!

The CADWELD

®

Process

Cover

Cable

Steel Disk

Crucible

Starting

Material

Ground Rod

Weld Cavity

Mold

Tap Hole

CADWELD

Welding

Material

- 6Z34VF14 Rod Hanging Basket Tray Clip (1 page)

- 766PM Far Side Box Support (1 page)

- 766PMD Far Side Box Support (1 page)

- CADDY MPVTI Low Voltage Mounting Clip (2 pages)

- H-Series CADDY PYRAMID Support System (3 pages)

- CADDY PYRAMID RL, PIPE RETAINERS (2 pages)

- CADDY PYRAMID Rooftop Equipment Support (4 pages)

- CADDY PYRAMID Single Post Support (1 page)

- CADDY PYRAMID TF Series, Fixed Height Tool-Free Supports (2 pages)

- CADDY ROD LOCK Anchor Screw (2 pages)

- CADDY ROD LOCK Beam Clamp (2 pages)

- CADDY ROD LOCK Channel Nut (2 pages)

- CADDY ROD LOCK L-Bracket (2 pages)

- CADDY ROD LOCK Strut (2 pages)

- CADDY SPEED LINK Riveted Accessories (4 pages)

- CADDY SPEED LINK SLK-Keyless Locking Device and Bulk Cable (2 pages)

- CADDY SPEED LINK SLK-Keyless Locking Devices (2 pages)

- CADDY SPEED LINK-Accessory Cables (1 page)

- CADDY SPEED LINK-SLK Cable End Accessories (4 pages)

- TSGB Series Screw Gun Bracket (2 pages)

- GLIDER Electrical Box Attachment (2 pages)

- H Series-Electrical Box Bracket (2 pages)

- ROD LOCK Plywood Pre-set Anchor (2 pages)

- ROD LOCK Strut End Bracket (2 pages)

- ROD LOCK Strut (2 pages)

- CADDY ROD LOCK Strut Nut (2 pages)

- CER4 Cable from Stud (2 pages)

- High Performance CADDY CAT HP J-Hook Assemblies (6 pages)

- KBT Wire Basket Tray Clip (1 page)

- MPCB1220 (2 pages)

- SBC Series, Beam Clamp, 3/8" and M10 (1 page)

- TSR200 Telescoping Strut Replacement Bracket (2 pages)

- TSRBS1625 Telescoping Box (3 pages)

- Universal Pedestal Clamp (2 pages)

- Branch Line Restraint Device (2 pages)

- Branch Line Restraint Strucural Attachment Fitting for Steel 12 gauge (2 pages)

- Branch Line Restraint, Structural Attachment Fitting for Concrete or Wood (2 pages)

- Branch Line Restraint, Structural Attachment Fitting with 3/8"-16 male thread" (2 pages)

- 510 CADDY EZ RISER (2 pages)

- 429 CADDY MACROFIX PLUS NI (1 page)

- Seismic Hanger Clamps (3 pages)

- CADDY PYRAMID Equipment Supports (3 pages)

- CADDY ROD LOCK Bottom-Mount Duct Bracket (2 pages)

- Bottom-Mount Duct Bracket, Narrow (2 pages)

- Top-Mount Duct Bracket (2 pages)