Calibration – Det-Tronics R8471NH34001,2,3 Single Channel Gas Controller, NH3 User Manual

Page 19

17

95-8529

1.1

2. At the end of the two second interval, the Low

LED goes out, the High LED blinks, and the digital

display shows the high alarm setpoint.

3. Two seconds later the High LED goes out and the

Auxiliary LED blinks. The digital display now shows

the auxiliary alarm setpoint.

4. Two seconds later the Auxiliary LED goes out and

the CAL LED blinks. The digital display now shows

the programmed calibration gas time.

5. After displaying the calibration gas time for two

seconds, the controller automatically leaves the

Setpoint Display mode and returns to the Normal

operating mode.

6. If adjustments to the setpoints are required,

perform the Setpoint Adjustment procedure. When

the setpoint levels are acceptable, record this

information for future reference.

SETPOINT ADJUSTMENT PROCEDURE

1. Determine the required alarm setpoint levels and

calibration gas time.

2. Press and hold the Set button for one second, then

release. The digital display indicates the present

low alarm setpoint and the Low LED blinks. Press

the Reset button to increase the reading or the Set

button to decrease the reading. (Holding the button

will cause the reading to change rapidly.)

3. When no changes to the setpoint level have been

made for 5 seconds, the Low LED goes out, the

High LED blinks, and the digital display shows the

high alarm setpoint. Press the appropriate button

(detailed in step 2 above) to obtain the desired

reading on the digital display.

4. When no changes to the setpoint level have been

made for 5 seconds, the High LED goes out, the

Auxiliary LED blinks, and the digital display shows

the auxiliary alarm setpoint. Press the appropriate

button to obtain the desired reading on the digital

display.

5. When no changes have been made for 5 seconds,

the Auxiliary LED goes out, the CAL LED blinks, and

the digital display indicates the calibration gas time.

Press the appropriate button to obtain the desired

reading on the digital display.

6. When no changes have been made for 5 seconds,

the controller automatically returns to the Normal

operating mode.

7. Record the new values for future reference.

NOTE

The alarm setpoints, calibration gas time, and

calibration data are stored in non-volatile memory

and are retained in the event of a power loss.

However, if power is interrupted while performing

the Setpoint Adjustment or Calibration procedure,

the entire procedure must be repeated when

power is restored.

CALIBRATION

SENSOR RESPONSE CHARACTERISTICS

In order to ensure that the gas detector will provide

maximum protection, it is important to understand the

operating characteristics of the sensor being used.

This is particularly true in the case of electrochemical

Cl

2

, SO

2

or NO

2

sensors, since their response is

different than that of other gas sensors.

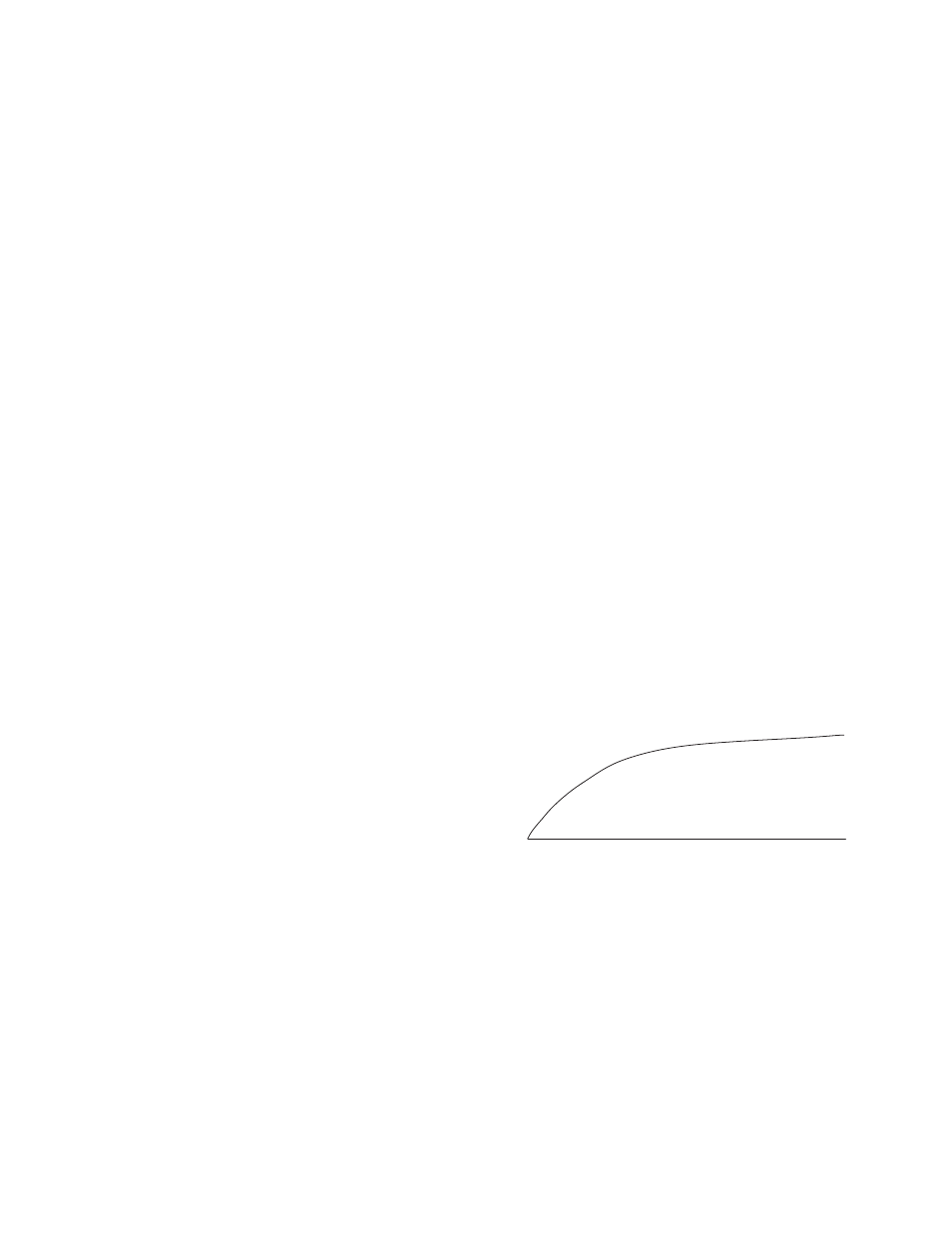

Figure 15 shows the response curve of a typical

sensor that has not been exposed to gas for 30 days

or longer.

TIME

OUTPUT

Figure 15—Response Curve of a Typical Sensor