Det-Tronics UD10 FlexVu Explosion-Proof Universal Display Unit User Manual

Page 10

8

95-8661

4.2

wIRINg pROCEDURE

noTe

The following section shows the output of the

UD10 wired to a generic 4-20 mA signal receiver

in various configurations. Since the UD10 can be

used with a variety of different detection devices,

information that is specific to each detector model

(wiring, calibration, HART menus, etc.) is covered

in an Appendix that is dedicated to that device.

Refer to the appropriate Appendix at the back of

this manual for specific information when wiring

the detection system. For information on devices

not covered in an Appendix, refer to the manual

provided by the device’s manufacturer.

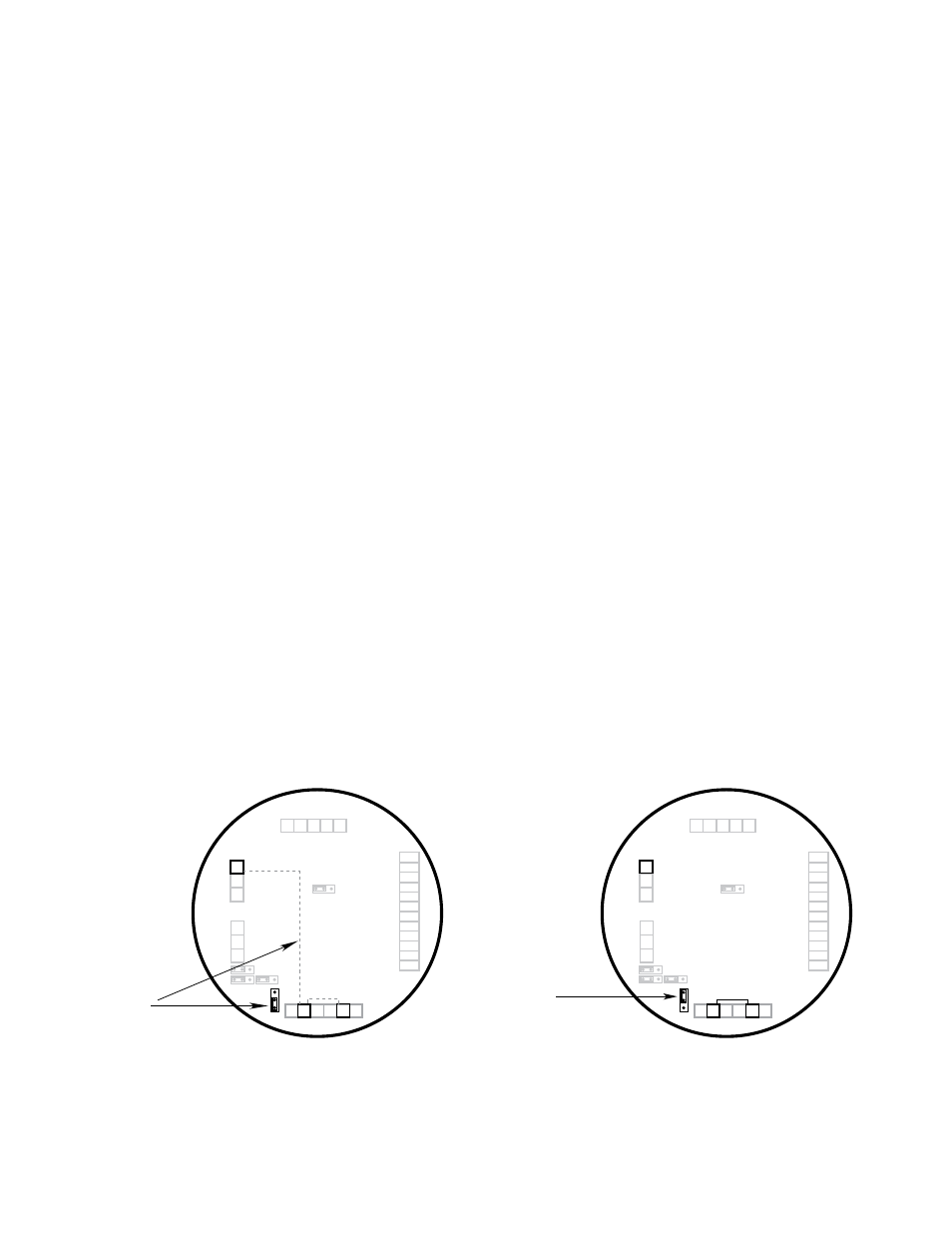

Figure 4 shows jumper plug P12 positioned to power the

4-20 mA loop from the main power source (non-isolated

output).

Figure 5 shows jumper plug P12 positioned for powering

the 4-20 mA loop from an external wire/jumper of from

a separate power source (isolated output).

Figure 6 shows the correct jumper positions and J2

terminal identification for using Foundation Fieldbus

communication.

Figure 7 shows the correct jumper positions and

J2 terminal identification for using MODBUS

communication.

Refer to Figure 8 for an illustration of the UD10 wiring

terminal board (see Figure 6 for Foundation Fieldbus

connections).

Figure 9 shows a UD10 Wired to a PLC using 3-Wire

Shielded Cable with a 4-20 mA Non-Isolated Sourcing

Output.

Figure 10 shows a UD10 Wired to a PLC using 4-Wire

Shielded Cable with a 4-20 mA Non-Isolated Sourcing

Output.

Figure 11 shows a UD10 Wired to a PLC with a 4-20 mA

Isolated Sourcing Output.

gREASE/lUBRICATION

To ease installation and future removal, ensure that all

junction box covers and sensor threads are properly

lubricated. If the need arises for additional lubrication, use

either Lubriplate grease (see Ordering Information for part

number) or Teflon tape. Avoid the use of silicone grease.

Figure 4—Position of Jumper P12 for

non-isolated 4-20 mA loop output

Sensor Connector

Power Supply Connector

Output

Loop

Connector

Fieldbus

Connector

R

ela

y Connect

or

P1

J2

J3

J4

P2

4-20 mA +

4-20 mA –

SHIELD

+

–

HIGH ALARM COM

HIGH ALARM NC

HIGH ALARM NO

AUX ALARM COM

AUX ALARM NC

AUX ALARM NO

LOW ALARM COM

LOW ALARM NC

LOW ALARM NO

FAULT COM

FAULT NC

FAULT NO

24 VDC

–

24 VDC

+

SHIELD

24 VDC

–

24 VDC

+

SHIELD

SHIELD

C

ALIBR

A

TE

24 VDC

–

4-20 mA

24 VDC

+

P1-3

P1-2

P1-1

J2-3

J2-2

J2-1

J4-1

J4-2

J4-3

J4-4

J4-5

J4-6

J4-7

J4-8

J4-9

J4-10

J4-11

J4-12

J3-1

J3-2

J3-3

J3-4

J3-5

P2-6

P2-5

P2-4

P2-3

P2-2

P2-1

P5

P9

P7

P12

P3

B2525

WHEN P12 IS

IN THIS POSITION,

P1-3 IS INTERNALLY

CONNECTED TO

P2-2 AND P2-5

Figure 5—Position of Jumper P12 for

isolated 4-20 mA loop output

Sensor Connector

Power Supply Connector

Output

Loop

Connector

Fieldbus

Connector

R

ela

y Connect

or

P1

J2

J3

J4

P2

4-20 mA +

4-20 mA –

SHIELD

+

–

HIGH ALARM COM

HIGH ALARM NC

HIGH ALARM NO

AUX ALARM COM

AUX ALARM NC

AUX ALARM NO

LOW ALARM COM

LOW ALARM NC

LOW ALARM NO

FAULT COM

FAULT NC

FAULT NO

24 VDC

–

24 VDC

+

SHIELD

24 VDC

–

24 VDC

+

SHIELD

SHIELD

C

ALIBR

A

TE

24 VDC

–

4-20 mA

24 VDC

+

P1-3

P1-2

P1-1

J2-3

J2-2

J2-1

J4-1

J4-2

J4-3

J4-4

J4-5

J4-6

J4-7

J4-8

J4-9

J4-10

J4-11

J4-12

J3-1

J3-2

J3-3

J3-4

J3-5

P2-6

P2-5

P2-4

P2-3

P2-2

P2-1

P5

P9

P7

P12

P3

B2526

WHEN P12 IS IN

THIS POSITION, A

SEPARATE POWER

SOURCE IS REQUIRED

TO POWER THE

4-20 MA LOOP