Balancing a wheel – COATS 1100 Series Balancer User Manual

Page 18

14 •

Important: Always read and follow instructions.

Balancing A Wheel

A variety of wheel configurations can be balanced

using this wheel balancer. Read through this section,

it will help in determining which balancing mode and

options are best suited for certain wheel assemblies.

Remember: As with any balancing procedure, first

remove any weights attached to the wheel, inspect the

tire and wheel, and use the most appropriate balancer

mounting method before beginning.

Dynamic Balancing

Choose a dynamic balance to balance a wheel using

two planes for correction. Select the weight option that

best fits the available weight locations on the rim.

Clip-on Weights - The standard default; used for most

passenger tire/wheel assemblies using the most com-

mon location for corrective weights. Clip-on weights

are placed on the inner (inboard) and outer (outboard)

rim flanges.

ALUS (Aluminum Wheels) - To balance aluminium

wheels you usually use a self-adhesive weight location

that is positioned differently from the clip-on weight

position(s) used in standard balancing. Be sure to use

the appropriate wheel data entry method since the

balancer calculates out of balance values based on the

wheel dimension measurements (DIM) entered for the

tire/wheel assembly.

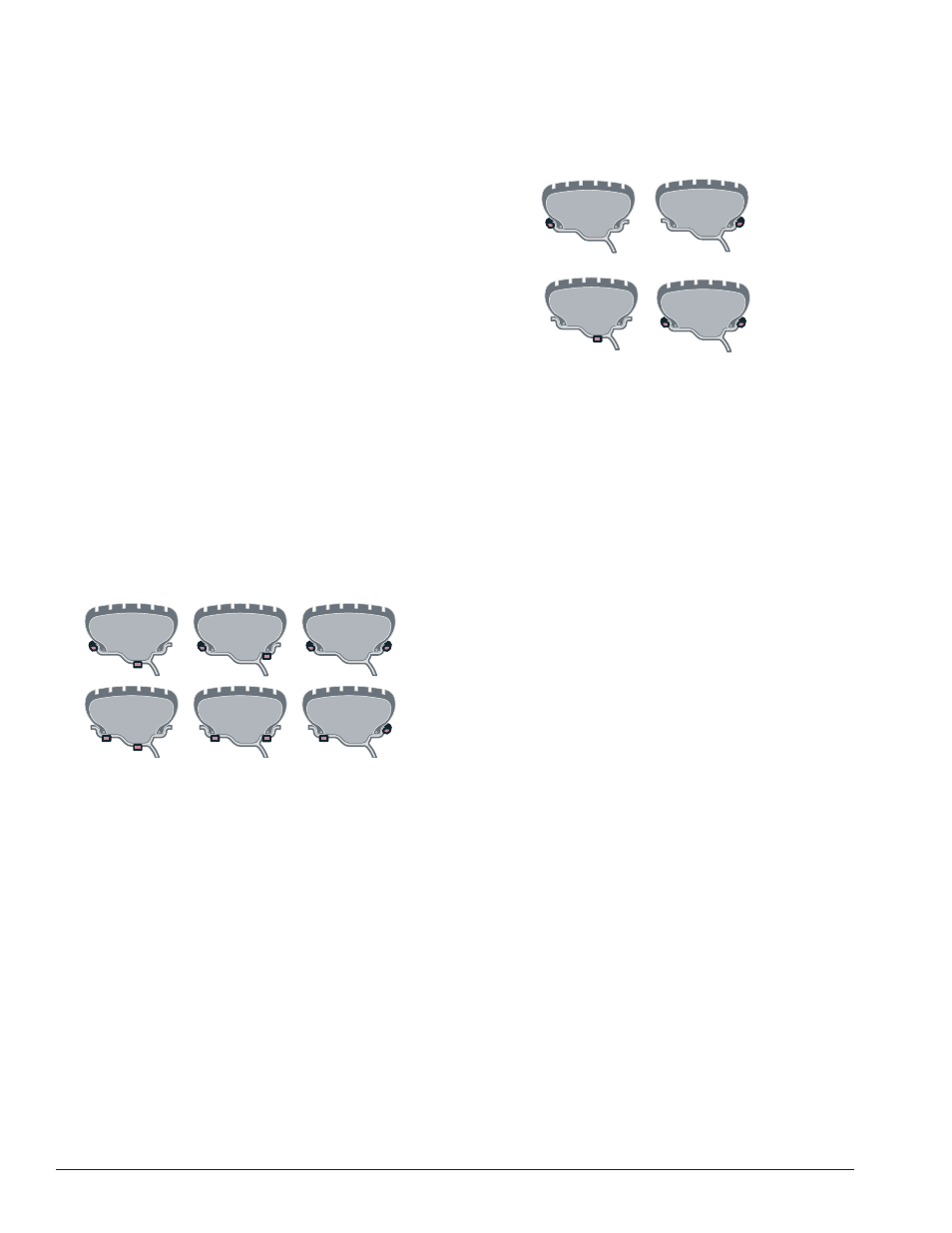

Figure 20 - Dynamic Balance Weight Locations

Note: When the machine is switched on, a standard

dynamic balance using clip-on weight locations is the

default setting.

Static Balancing

Choose a static balance to balance a wheel using one

plane for correction. Place the single corrective weight

at top-dead-center (12 o’clock) on either flange, at the

center of the rim channel, placed inward either side, or

split on either sides.

Figure 21 - Static Balance Weight Locations

Note: When in static mode, you only need to input the

DIAMETER wheel measurement.

Important: If you decide to use the rim channel for

corrective weight placement, remember you may need

to adjust the DIAMETER measurement input. Typically

you would make it 2 or 3 inches less than the actual tire/

wheel diameter.