Direct drive, Caution, Optional combi adaptor – COATS 1001 & 1001SC Balancer User Manual

Page 22

16 • COATS 1001 Wheel Balancer

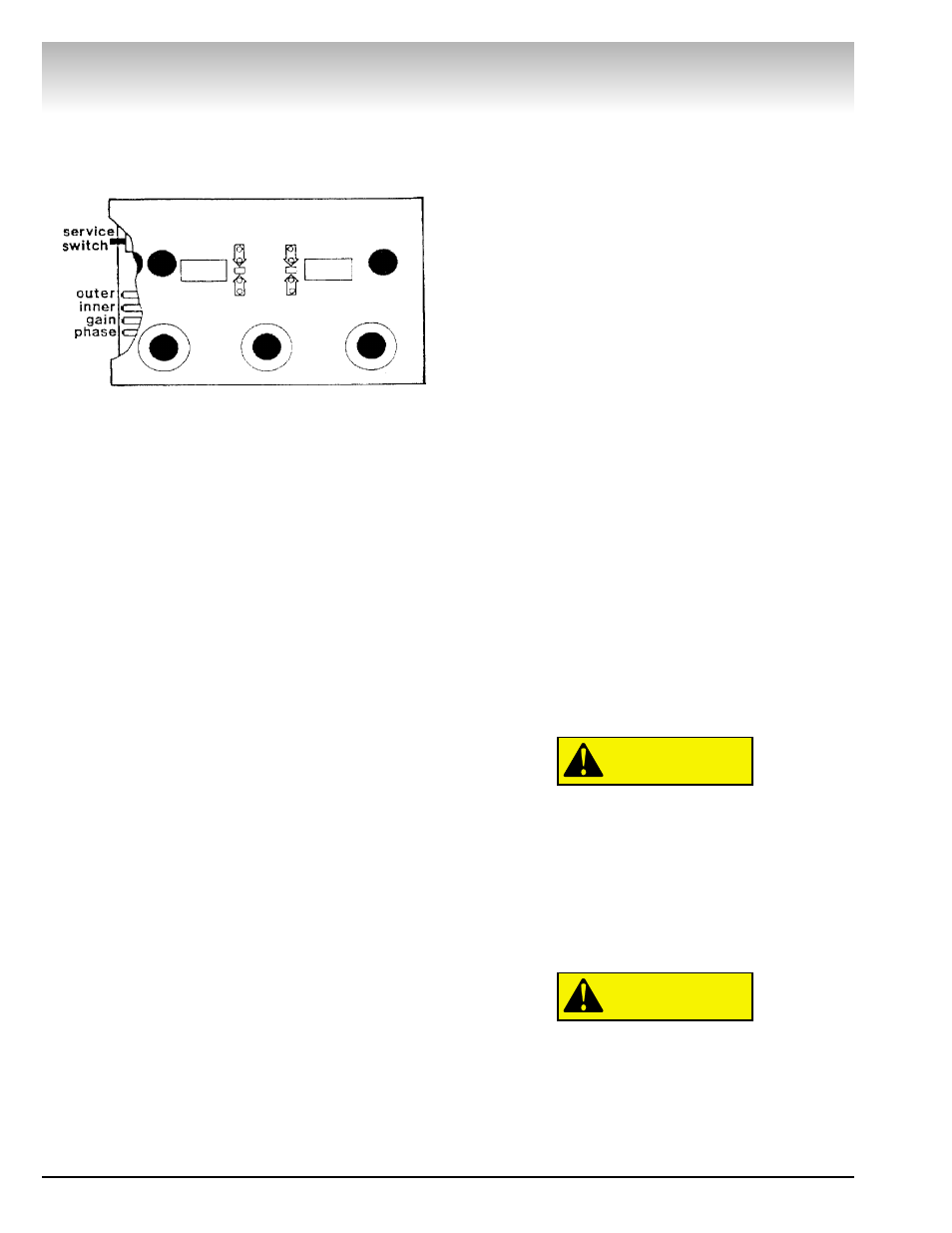

Direct Drive

Calibration Adjustment Procedure

Note: Do not preform Calibration Adjustment when

motor is excessively hot.

1. Perform the calibration check procedure steps

one (1) through seven (7) (See Page 15).

2. Remove the four (4) screws holding the control

panel shroud and lift the shroud off.

3. Place an 8 ounce (226 gram) test weight on outer

rim of wheel.

4. Set service switch to upper position (test mode).

Press the START button. The display will now read

“TEST”. The outer and inner position lights will now act

as bar graphs. First adjust the gain trimpot until the

minimum number of lights are on or flashing.

Alternately adjust the gain and phase trimpots until all

the lights are off.

5. Set service switch to bottom position (NORM).

Remove the test weight and then balance the wheel.

A maximum imbalance of .07 ounce (2 gram) on the

inner and outer weight displays is allowed.

6. Place a 4 ounce (113 gram) test weight on the

outer rim.

7. Set the service switch to center position (non-

stop). Press the START button. Wheel will come up to

speed, but not go into braking mode. Now adjust the

outer weight trimpot (affects outer magnitude). After

each adjustment of the trimpot, press and hold the

START button until a new reading appears on the dis-

play. Continue this procedure until the outer weight

display reads 4 ounce (113 gram). The inner weight

reading should be .21 ounce (6 gram) or less. Set the

service, switch to the bottom position so that the

wheel will brake to a stop.

8. Place the 4 ounce (113 gram) test weight on the

inner rim. Set service switch to center position. Press

the START button.

9. Adjust the inner weight trimpot (affects inner

magnitude) until display reads 4 ounce (113 gram). Use

the same procedure as in Step 7. The outer weight

reading should be .21 ounce (6 gram) or less. Set the

service switch to the bottom position (NORM).

10. Calibration is now complete. To return the bal-

ancer to the normal operating mode: Switch off the

power and then turn it on again (On/Off switch located

on rear of machine). This clears the high accuracy

mode and the balancer is ready to use.

Optional Combi Adaptor

Combi adapter may be used for 3, 4, 5, 6, 8, or 10-

Lug wheels by installing swivel plates in Combi plate

hole pattern. Set up adapter as follows:

Install a swivel plate in combi plate “common” hole.

Line up number gear to match “345” mark with index

mark on swivel plate. Insert swivel plate bolt through

back of combi plate and run up. DO NOT TIGHTEN.

Note: This swivel plate is used for all bolt circle pat-

terns.

Install proper number of swivel plates in combi plate

holes marked “3”, “4”, or “5” as required. Insert swivel

plate bolts through back of combi plate and run up, DO

NOT TIGHTEN. Ensure that index marks on all swivel

plates line up with the appropriate “3”, “4”, or “5” mark

on the number gear.

Install combi adapter on wheel Run up lug nuts by

hand. Tighten lug nuts with adapter wrench, using a

star or criss-cross pattern.

Lug nuts must be centered and threaded at

least four full turns Reverse lug nuts as

required. Use only adapter wrench fur-

nished with adapter Do not use air tools or

impact wrenches.

Tighten swivel plate bolts with alien wrench.

Attach wheel and adapter to faceplate with two

faceplate nuts.

Faceplate nuts must be hand tightened.

Rotate wheel while tightening to ensure

centering.

Adapter should remain on faceplate for additional

wheels with same bolt circle.

CAUTION

CAUTION

High Accuracy Mode For Calibration