Clamp application free-end clamps – BAND-IT UL4000-C Cordless Ultra-Lok Tool User Manual

Page 9

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

Document # P08986 Rev. A

© Copyright

BAND-IT-IDEX, Inc. 2012

All rights reserved

www.BAND-IT-IDEX.com

Page 9 of 14

UL4000-C

UL4000-C220

Ultra-Lok Tool

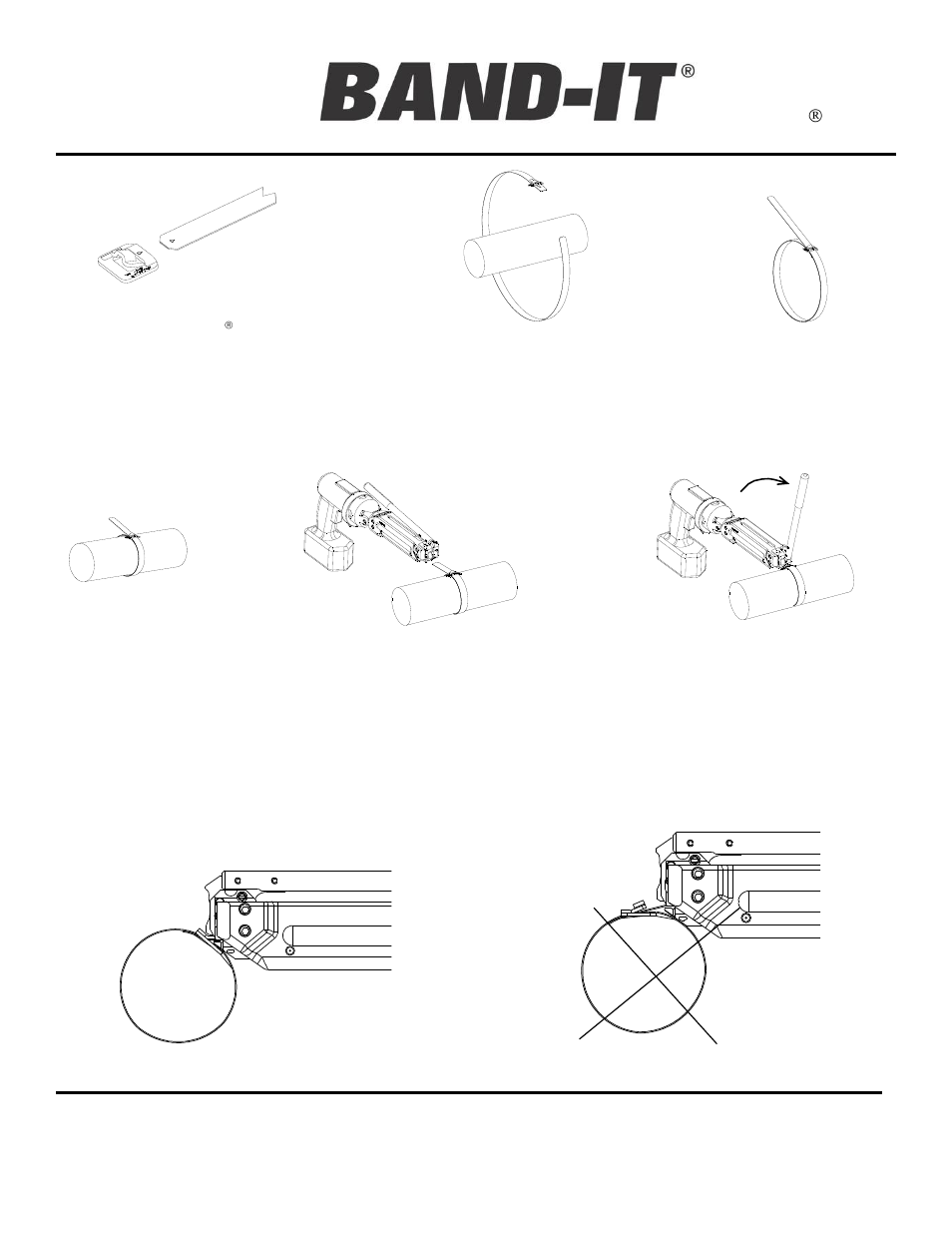

Clamp Application

Free-End Clamps

Push all

the way

forward

to a solid

stop

1. Break off an Ultra-Lok Free-End

tie from the roll. Slide the buckle

onto band with indented arrows

pointing in same direction and

same side up. Slide buckle all

the way onto band until it comes

to a stop between the two buckle

dimples at opposite end of tie.

2. Wrap tie around object to be clamped.

Insert the tie through buckle once for

single-wrap or twice for double-wrap.

Double-wrapped clamps have more

than 3 times the loop-tensile strength.

3. If desired, you may pre-

form a clamp in the same

fashion as step 2, or use a

preformed clamp in place

of a Free-End

4. Position the tie on the

object you are clamping.

Pull the wrapped tie

hand-tight. Slightly bend

the tail up to keep the

clamp in place

5. Actuate Drill until Tension Block is all the

way forward against the tool body. Set Drill

to clock-wise rotation. With cut-off handle

down as shown, insert clamp tail into tool

head slot.

Actuate Drill until Drill‟s built-in

clutch disengages. If Tension Block comes

near its end of travel, release actuator switch

and reverse Drill to pull more on clamp tail.

Excessive use of disengaging Drill Clutch

indicated by a loud ratcheting sound leads to

premature wear of tension screw.

6. Do not force the tool against the

clamp; it may result in a folded clamp

tail.

7. Pull the cut-off handle forward to cut

tail off and form a lock, then return

handle to the down position. Reverse

drill and feed clamp tail out of tool.

8. Tap down buckle shroud to complete

clamp. Tool is ready for next clamp.

Correct position of tool

while tensioning

Incorrect position of tool

while tensioning

DO NOT

FEATHER the

drill’s TRIGGER

when tensioning a

clamp.

USE FULL SPEED

OF TOOL