APG DCR-1004 user manual User Manual

Page 8

DCR-1003 and DCR-1004

Rev. A3, 10/08

8

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • [email protected]

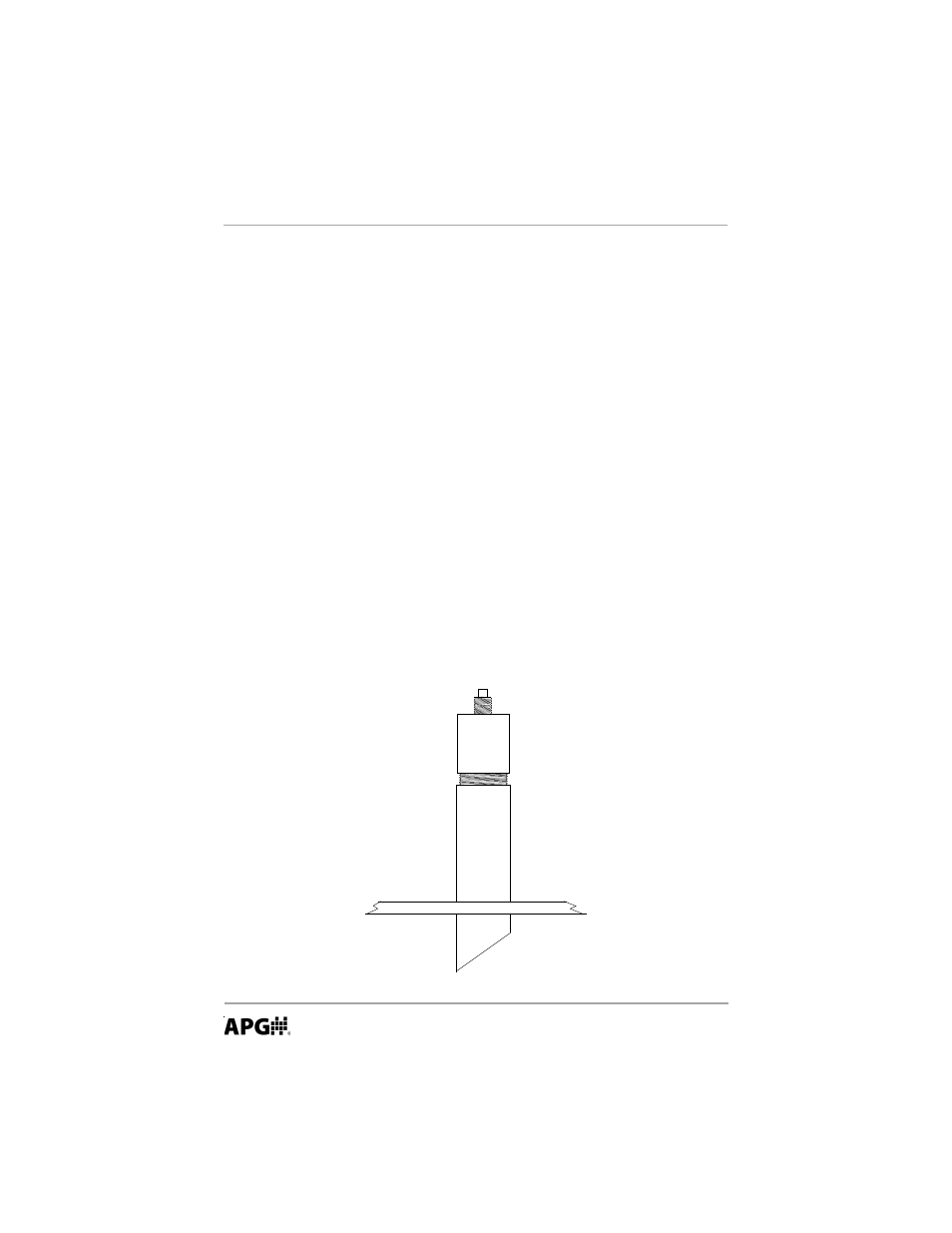

Stand Pipe Mounting

The stand pipe should be as large in diameter and as short in length as

possible. Mount the sensor above the highest anticipated material by at least

the published blanking distance.

The stand pipe should be seamless to provide a smooth path for the sound

waves to propagate into the tank. Because the sound waves will concentrate

along the inside wall of the pipe, any seams from couplers, nipples, and welds

will cause echo returns that will be picked up by the sensor. The sensor

blanking will need to be changed to a distance greater than the length of the

pipe (found on page 15; mode 5).

The end of the stand pipe should extend inside the tank and be cut to a 45°

angle. Make sure that the cut is clean and free from burs. If the standpipe is cut

at 90°, there will develop a standing wave echo at the end of the pipe that will be

seen by the sensor as a target. If a 45° cut is not feasible in your application,

then the cut should be made as close to 45° as possible (often, even a 10° cut

will shrink the standing wave enough to allow the sensor to see past it).

To avoid false Echoes, the stand pipe should be installed where there is a

clear sound path perpendicular to the detection surface and where the sound

path will not intersect vessel fill spouts, rough vessel walls, ladders…etc. Any

angle off perpendicular will degrade the performance of the sensor.

Top of Tank

Stand Pipe

10-45

o

CUT