Brake lathes, Electrical wiring requirements, Assembly instructions – AMMCO 700 Vehicle Brake Lathe User Manual

Page 19

AMMCO 700/705/710 Brake Lathes • 13

Electrical Wiring

Requirements

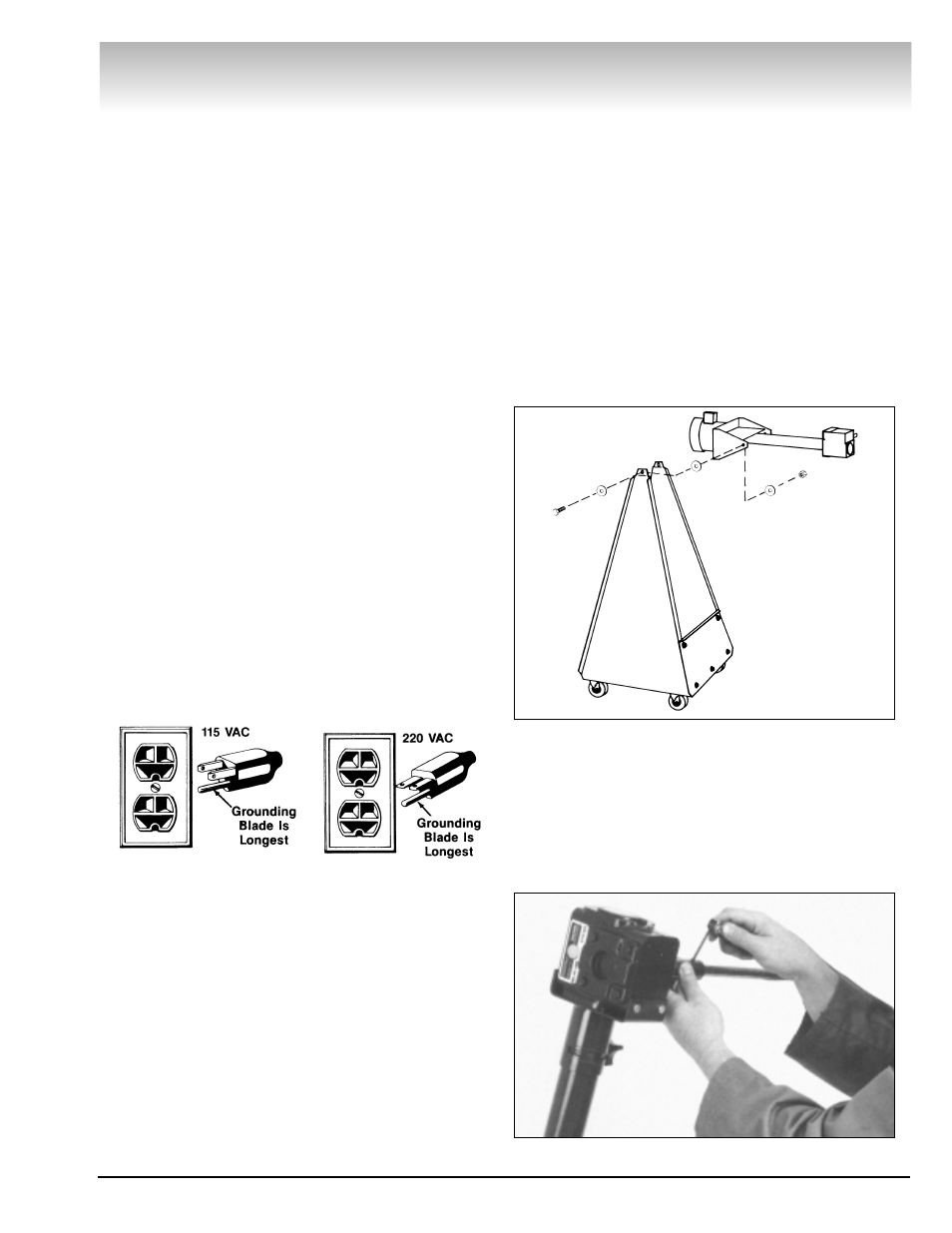

The driving unit should be electrically grounded to pro-

tect the operator from shock. The unit is equipped with

an approved 3-conductor cord and a 3-prong grounding

type plug to fit the proper grounding type receptacle. If

your unit is for use on 115 volts, it has a plug and outlet

as illustrated in Fig. 22. Use only 3-wire extension cords

which have 3-prong grounding type plugs and 3-pole

receptacles which accept the unit’s plug. 230 volt units

use a plug and outlet like those illustrated in Fig. 23.

Any line voltage lower or higher than ten percent

(10%) of nominal will cause problems with the machine.

If the machine receives below or above the design limit,

erratic operation will ensue with a degradation in com-

ponent reliability and life. By law the power company

must supply power within the ten percent (10%) limit of

nominal line. It is up to the customer to see that his

facility is properly wired and is supplying power to the

machine within its design limits. Inadequate voltages

and wiring will only produce problems.

AMMCO electrical and electronic based machines are

designed for nominal line voltages with variations of ten

percent (10%) around the nominal, i.e.; 115 volt input

could vary from 103 volts on the low side to 127 volts

on the high side. These percentages also apply to 230

VAC based products.

Replace or repair damaged or worn cords immediately.

Thermal Overload Circuit Breaker

The driving unit is equipped with a thermal overload

circuit breaker, it is located in the ON/OFF switch. If the

drive unit’s function is interrupted due to an overload,

this switch has to be reset.

1. Turn the switch to the OFF position.

2. Unplug the drive unit from the power source.

3. Allow 10-15 minutes for the unit to cool down.

4. Make sure the cause of the overload is located and

eliminated.

5. Plug drive unit back into power source.

6. Reset circuit breaker.

Assembly Instructions

The rotor driving unit contains three (3) main assem-

blies. They are:

1. Floor Stand

2. Motor/Gearbox Unit

3. Lug Adapter Set

1. Center the motor/gearbox assembly between the

uprights of the floor stand. Align the holes in the motor

bracket with the holes in the uprights. From the outside,

insert a bolt and washer through the holes. Add a

washer between the upright and motor/gearbox unit,

then slide a washer and locknut over the bolt on the

inside of the floor stand. Repeat on the opposite side,

Fig. 24.

2. Tighten the motor bracket bolts until the

motor/gearbox assembly will hold steady in any position

it is rotated to.

3. Slide the drive shaft over the end of the gearbox

output shaft. tighten the two (2) set screws to securely

hold the shaft in place, Fig. 25.

Brake Lathes

Figure 24

Figure 25

Figure 23

Figure 22