Brake lathes – AMMCO 700 Vehicle Brake Lathe User Manual

Page 14

Set-Up and Machining

1. Properly mount the lathe to the vehicle, as described in the

Section LATHE MOUNTING PROCEDURES.

2. Properly secure the rotor to the hub, as described in the

section MOUNTING OF LUG ADAPTER.

3. Install a silencer band on the outside diameter of the rotor

to dampen vibrations during cutting.

4. Prepare and install the Rotor Driving Unit.

Note: It is not necessary to secure the opposite rotor for con-

sistent speed.

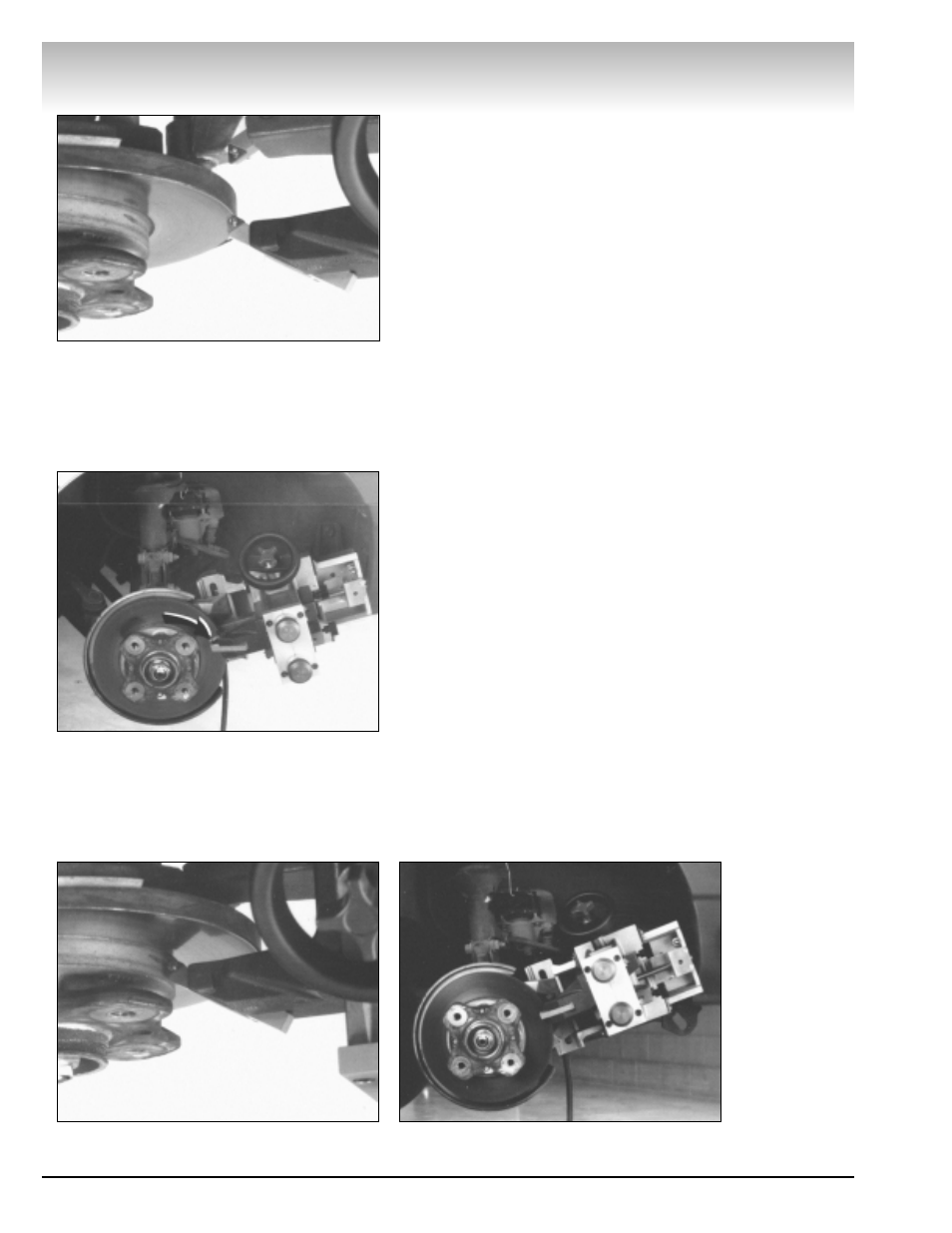

5. Check to insure that the cutting bits are clear of the rotor,

Fig. 12. Plug the Lathe into the switched outlet on the Rotor

Driving Unit, and turn on the Rotor Driving unit.

Note the position of the cutting bits relative to the rotation of

the rotor. The direction of rotation must be into the top face of

the cutting bits, Fig. 13. Correct the cutting bit direction if nec-

essary.

6. Double check the positions of the cutting bits relative to the

rotor. Each should clear the rotor to allow travel to the inner

diameter of the braking surface, Fig. 14.

7. Make sure the engagement knob is loose.

8. Check to insure there is enough travel in the carriage to

allow the cutting bits to reach the inner diameter of the braking

surface. Turn the handwheel counterclockwise to move the car-

riage toward the rotor.

Note: Do Not jam cutting bits into the hat or raised portion of

the rotor.

9. Position the cutting bits about 1/2" in from the outer edge

of the braking surface, Fig. 15.

Brake Lathes

8 • AMMCO 700/705/710 Brake Lathes

Figure 12

Figure 13

Figure 14

Figure 15