AMMCO 940175 Poly V-Belt and Pulley Kit User Manual

Caution, Installation instructions

940175

Poly V-Belt and Pulley Kit

Installation Instructions

AMMCO Tools, Inc. • Hennessy Industries • 1601 J.P. Hennessy Drive, LaVergne, TN 37086-3564

(800) 688-6359 • (615) 641-7533 • (615) 641-5104 FAX

Installation Instructions – 3000 and 7000 Lathes

Discard the pin supplied with

the new pulley. The pin has no

function on the 3000 or 7000

lathe and may damage the lathe if installed.

1.

Remove the v-belt and discard.

2.

Back the set screws fully out of the v-belt pulleys.

3.

Remove and discard the old pulleys.

4.

Install the new pulleys using the set screws provided.

NOTE: On older lathes without the drive shaft key, the

pulley set screws must engage the 2 recesses in the

pulley shaft to properly position the pulley for correct v-

belt alignment.

5.

Align the motor pulley to the wormshaft pulley using

a straight edge.

6.

Install the new v-belt on the pulleys.

7.

Poly V-Belt Tension Adjustment:

The poly v-belt should be adjusted to deflect 3/32”

with a 5 pound push on the belt. The ideal tension is

the lowest tension at which the belt will not slip

under the highest load.

Check and adjust as required.

8.

Apply the decal provided to the top outside surface of

the belt cover.

940168 10/96

© COPYRIGHT 1996 HENNESSY INDUSTRIES AND AMMCO TOOLS ALL RIGHTS RESERVED PRINTED IN U.S.A.

CAUTION

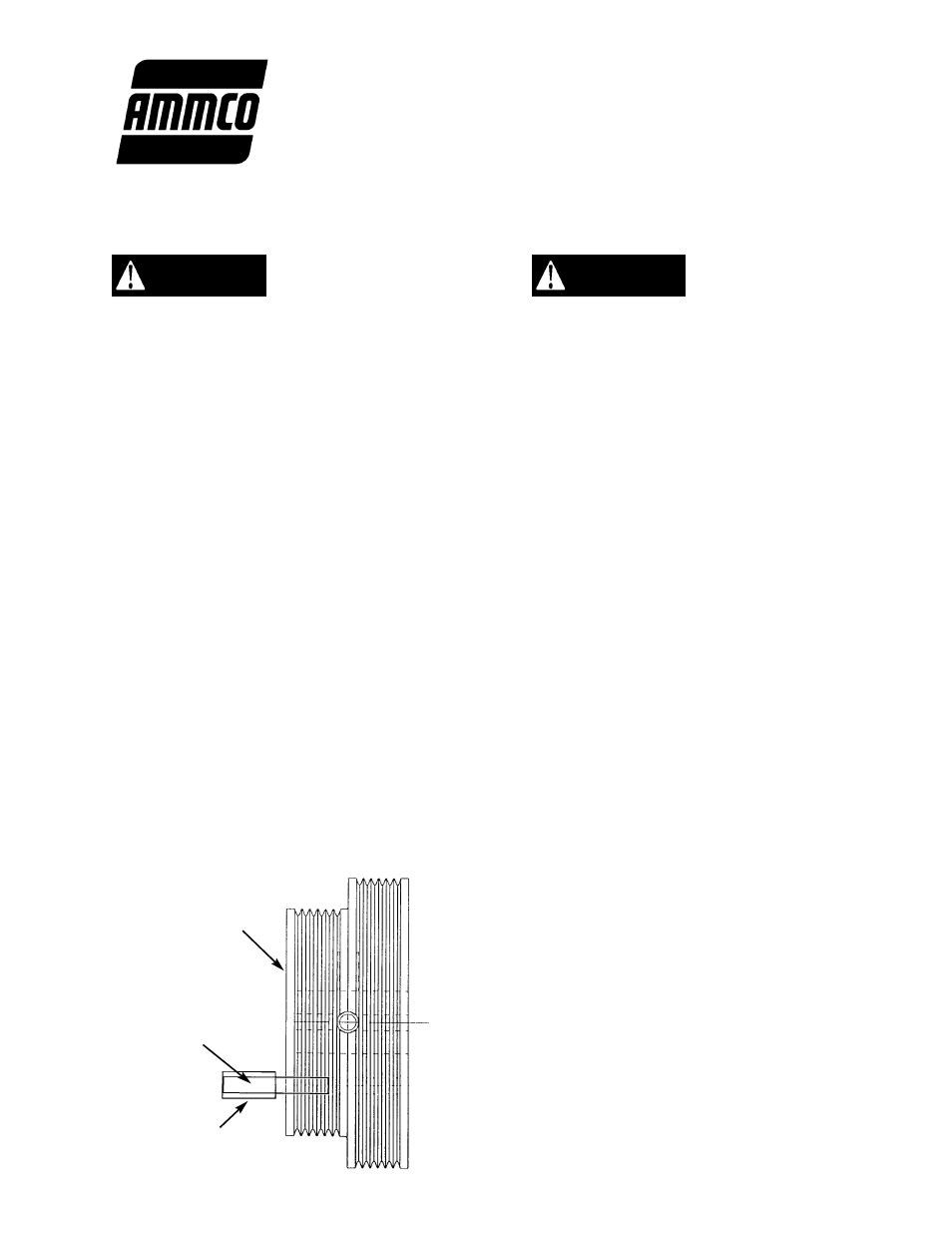

Pulley

Pin

Rubber Tube

Installation Instructions – 4000 Lathe

To avoid damaging the lathe,

install the pin in the small hole

of the pulley before installing

the pulley on the lathe.

1.

Place the larger (worm) pulley on a bench with the

small diameter facing up.

2.

Drive the pin into the small hole of the pulley until the

pin protrudes 3/4” from the face of the pulley.

3.

Slip the rubber tube over the pin.

4.

Remove the v-belt from the lathe and discard.

5.

Back the set screws fully out of the v-belt pulleys.

6.

Remove and discard the old pulleys.

7.

Install the new pulleys using the set screws provided.

NOTE: On older lathes without the drive shaft key, the

pulley set screws must engage the 2 recesses in the

pulley shaft to properly position the pulley for correct v-

belt alignment.

8.

Align the motor pulley to the wormshaft pulley using

a straight edge.

9.

Install the new v-belt on the pulleys.

10. Poly V-Belt Tension Adjustment:

The poly v-belt should be adjusted to deflect 3/32”

with a 5 pound push on the belt. The ideal tension is

the lowest tension at which the belt will not slip

under the highest load.

Check and adjust as required.

11. Apply the decal provided to the top outside surface of

the belt cover.

CAUTION