Brake lathes – AMMCO 700 Vehicle Brake Lathe User Manual

Page 11

AMMCO 700/705/710 Brake Lathes • 5

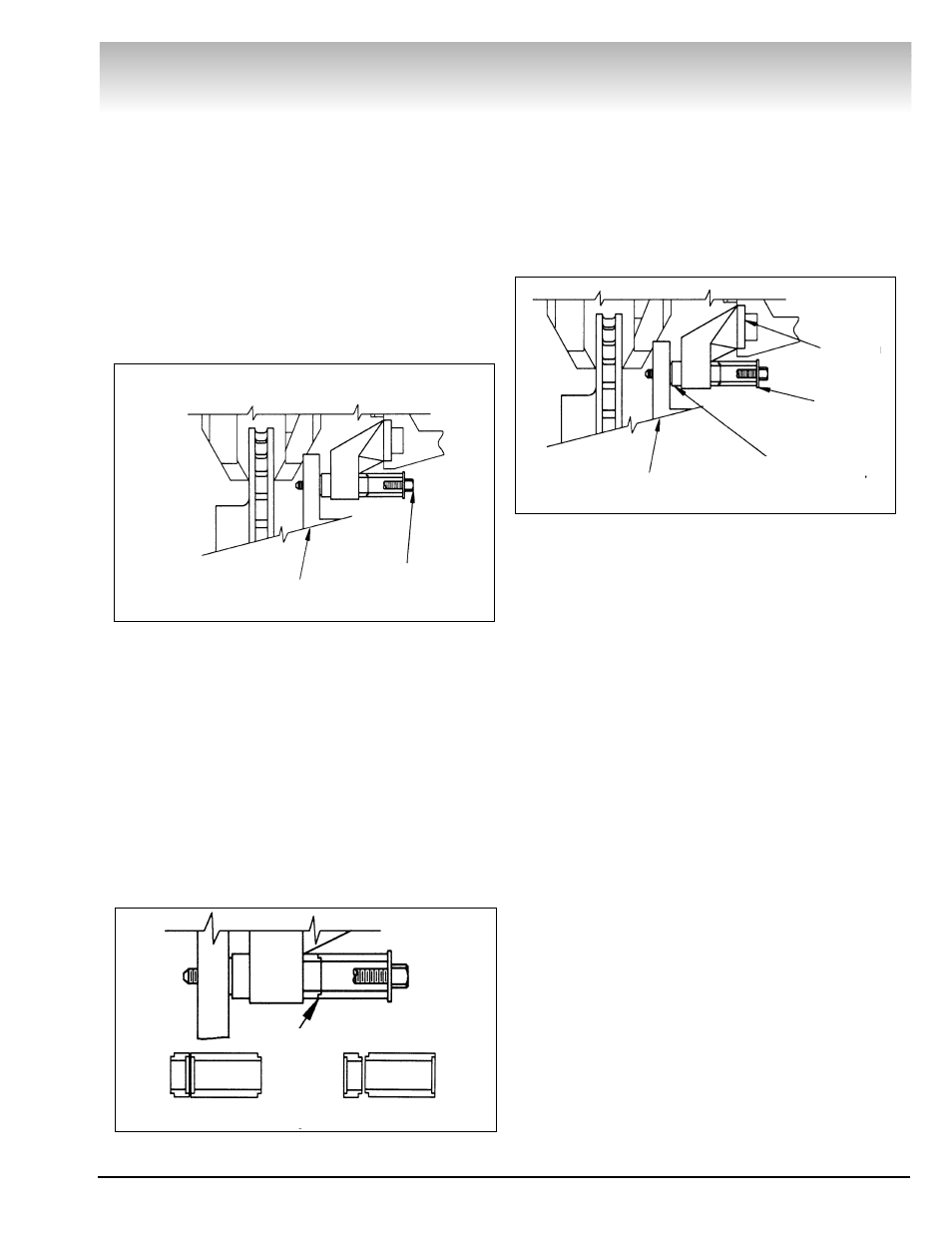

Use of Mounting Hardware

1. The lathe mounting hardware was designed for

use on vehicles with a pressed hub/knuckle/rotor

assembly or where removal of the rotor is difficult or

inefficient.

2. The vehicle’s caliper bolts can be used to mount

the lathe if the holes in the steering knuckle or caliper

mounting bracket are threaded and on the inboard side

of the rotor, Fig. 6. Also, the vehicle’s caliper bolts

should be 1-1/2" in length or longer. Otherwise, the

mounting bolts and nut plates provided in the hardware

package will be needed.

3. Whether you are mounting the lathe with the vehi-

cle caliper bolts or with the mounting bolts provided in

the hardware kit, various combinations of spacers may

be required to take up the space between the bolt

heads and the lathe mounting bracket to keep the bolt

from interfering with the rotor.

Note: When using more than one spacer, care should

be taken to use the tongue and groove configuration to

prevent misalignment, Fig. 7. If the small 1/8" spacer is

required, it should be placed on the caliper bolt last

since it does not have the counter-bore the other spac-

ers possess.

4. The spacers may also be used to achieve the

proper lathe position on the rotor, by placing the spac-

ers on the caliper/mounting bolts between the lathe

mounting bracket and the caliper mounting bracket,

Fig. 8.

5. The flat washers, provided in the hardware kit,

should be used between the caliper bolt head and the

spacers to insure a good seat for the bolt head, Fig.8.

Brake Lathes

Figure 7

Figure 8

Figure 6

Inboard Side

(Toward Vehicle)

Outboard Side

(Away From

Vehicle)

Correct Configuration of

Spacers

Incorrect Configuration of

Spacers

Inboard Caliper

Mounting Bracket

Caliper Bolt

(1-1/2" Min. Length)

Flate

Washer

Spacer - Adjust Lathe

Placement on Rotor

Inboard Caliper

Mounting Bracket

Lathe

Mounting

Bracket