Brake lathes – AMMCO 700 Vehicle Brake Lathe User Manual

Page 15

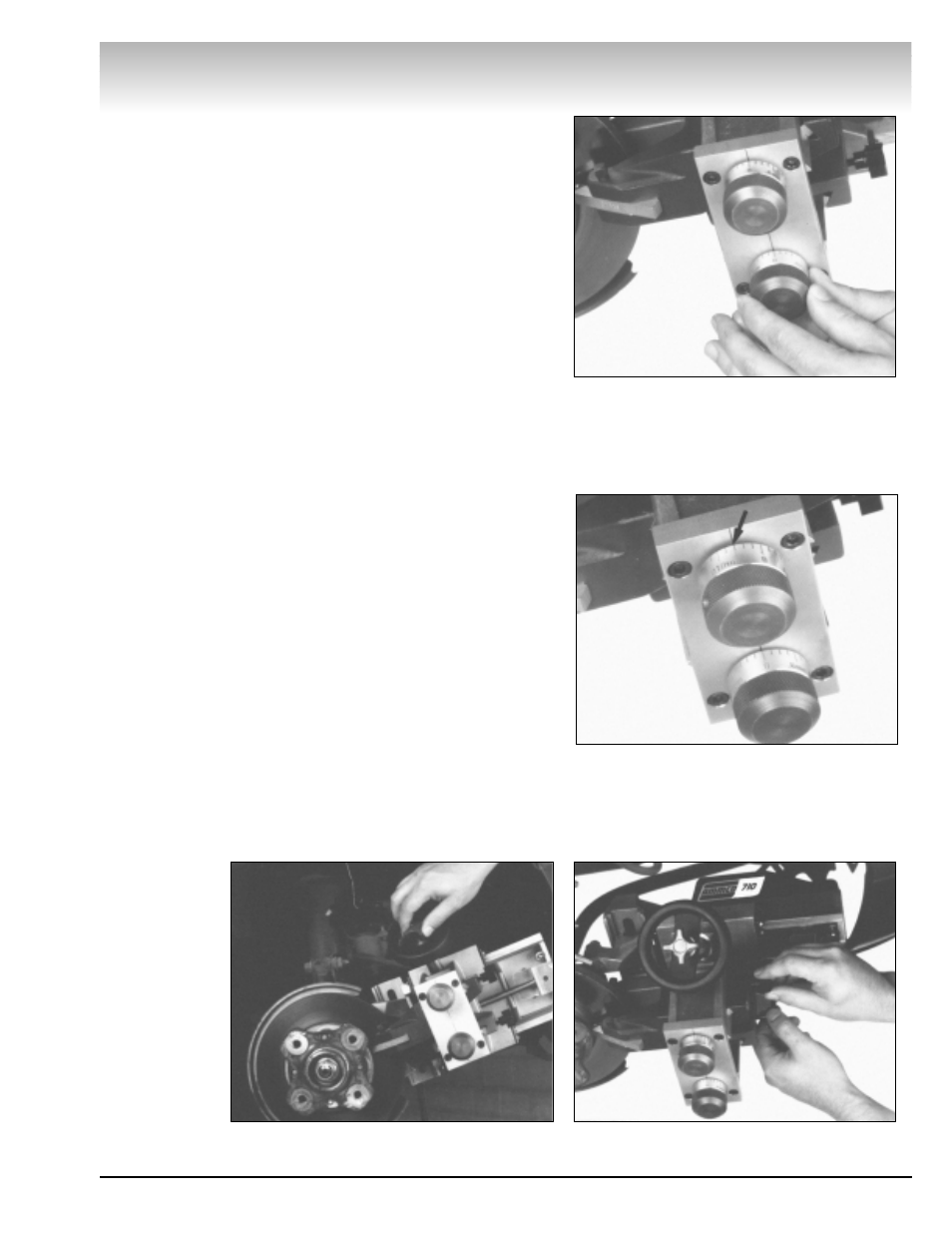

10. Turn the (blue) depth-of-cut knob clockwise to advance

the outboard cutter until it lightly contacts the brake surface.

Holding the knob still, rotate the micrometer dial to zero, Fig. 16.

11. Turn the (red) depth-of-cut knob clockwise to advance the

inboard cutter until it lightly contacts the brake surface. Holding

the knob still, rotate the micrometer dial to zero.

Note: Once you have zeroed a dial, never use the dial microm-

eter to advance or withdraw a cutting bit; the dial may slip, los-

ing the zero position. Use the depth-of-cut knob to advance or

withdraw the cutting bit.

12. Advance the carriage with the handwheel until the out-

board cutting bit reaches the inside edge of the braking surface

of the rotor.

13. Turn the depth-of-cut knobs individually to set each cut-

ting bit to the desired depth-of-cut (usually .006" per side or

three divisions of the micrometer), Fig. 17.

Note: A .006" depth-of-cut per side (a total of .012") will recon-

dition most rotors, although some severely grooved rotors may

require more than one cut.

Cuts may be .002" -- .010" deep.

14. Tighten the cutter locking knobs, Fig. 18.

15. Tighten the engagement knob in the center of the hand-

wheel, Fig. 19. This will start the cut. When the cutting bits have

cleared the outer edge of the rotor, loosen the engagement

knob to stop the carriage.

16. Turn off the Rotor Driving Unit and inspect both surfaces

of the rotor.

17. If part of the brake surface was not cut, leave the cutters

locked in position. Turn on the Rotor Driving Unit. Slowly turn the

handwheel to move the carriage to the inside edge of the brak-

ing surface.

18. Repeat steps 13, 14, 15, and 16.

Brake Lathes

AMMCO 700/705/710 Brake Lathes • 9

Figure 16

Figure 17

Figure 18

Figure 19