8 air cleaner assembly, 1 air cleaner assembly removal, 2 air cleaner assembly installation – JLG 4017 Service Manual User Manual

Page 95: 9 engine replacement, 1 engine removal, Air cleaner assembly, Engine replacement, Air cleaner assembly removal, Air cleaner assembly installation, Engine removal

7.9

4017

Engine: Perkins 1004-40T

3. Install the muffler to the exhaust pipe and bolt the

muffler to the side of the frame.

4. Install the clamp securing the muffler to the exhaust

pipe.

5. Install the clamp securing the muffler to the tail pipe.

6. Adjust the muffler, exhaust and tail pipes for proper

clearance then tighten all clamps.

7. Connect the negative (-) battery cable to the negative (-)

battery terminal.

8. Start engine and check for exhaust leaks at all

exhaust connections. Adjust or repair as needed.

9. Install the belly pan.

7.8

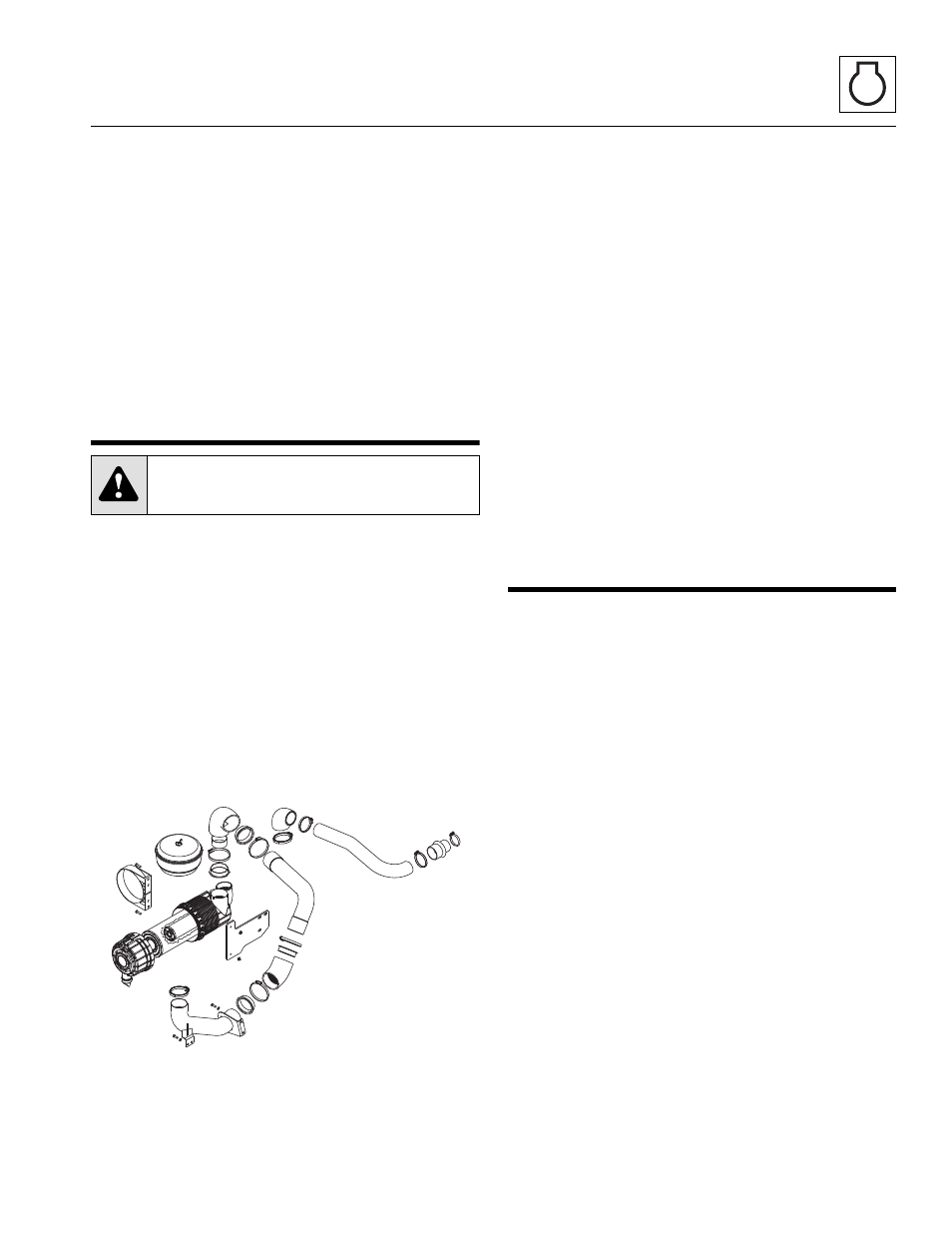

AIR CLEANER ASSEMBLY

IMPORTANT: Refer to the appropriate Operator &

Safety Manual for your machine for the correct element

change procedure.

7.8.1

Air Cleaner Assembly Removal

1. Open the engine cover.

2. Disconnect low pressure indicator wire connection.

3. Remove the clamp securing the air intake elbow to

the air cleaner assembly. Lift the air intake elbow off

the air cleaner.

4. The reducing insert and the reinforcement ring

should be removed along with the air intake tube.

5. Remove the clamp securing the air outlet elbow. Lift

the air outlet elbow off the air cleaner.

6. Remove the two capscrews and ripp nuts securing

the air cleaner mounting bracket to the air cleaner

mounting plate. Remove the air cleaner assembly.

7.8.2

Air Cleaner Assembly Installation

Note: Apply Loctite

®

242 threadlock to the capscrew

threads before installation.

1. With the air cleaner assembly attached, install the air

cleaner mounting bracket using capscrews and ripp

nuts.

2. Place the loosened clamps over the air intake elbow

along with the reducing insert and the reinforcement

ring, and install elbow on the air cleaner assembly.

3. Place the loosened clamps over the air outlet elbow

and install elbow on the air cleaner assembly.

4. Connect low pressure indicator wire connection.

5. Adjust and tighten both clamps before starting the

machine.

6. Close and secure the engine cover.

7.9

ENGINE REPLACEMENT

7.9.1

Engine Removal

Note: The radiator and oil cooler must be removed from

the machine before engine removal. Refer to

7.4, “Engine Cooling System.” Several additional

components must be removed before engine removal.

They will be addressed in the following procedures.

1. Park the machine on a firm, level surface, fully

retract the boom, lower the boom, place the

transmission control lever in NEUTRAL (N), engage

the park brake and shut off the engine.

2. Place an Accident Prevention Tag on both the

ignition key switch and the steering wheel, stating

that the machine should not be operated.

3. Open the engine cover. Allow the system fluids to

cool.

Note: ALWAYS replace elastic locknuts with new elastic

locknuts to help ensure proper fastening.

4. Remove the engine cover, radiator guard plate and

the engine belly pan.

5. Remove the radiator overflow bottle and hoses.

6. Refer to Section 7.4.3, “Radiator/Oil Cooler and

Replacement,” to remove the radiator/oil cooler.

7. Loosen the clamps on each heater hose on the

engine. Plug the heater hoses if necessary.

CAUTION:

NEVER run the engine with

only the inner safety element installed.

MZ0120