2 transmission inspection and internal repair, 3 transmission installation, Transmission inspection and internal repair – JLG 4017 Service Manual User Manual

Page 81: Transmission installation

6.5

4017

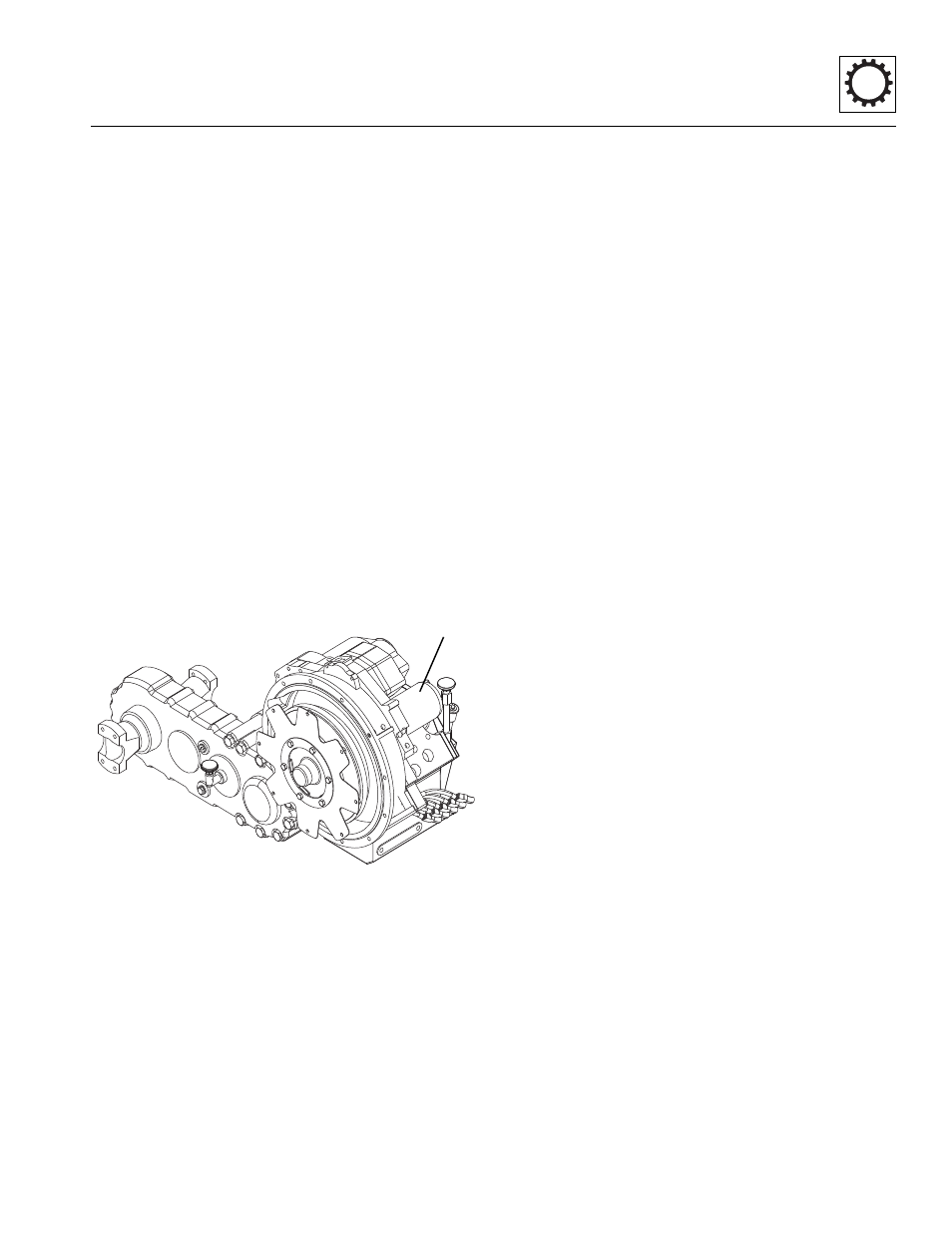

Transmission:

23. Remove the ten bolts and washers holding the

transmission to the engine.

24. Remove the four capscrews and four lockwashers

securing each rear transmission mount to the

transmission.

25. Remove the two transmission mounts from the

machine.

26. Inspect the rubber mounts. Replace the mounts if

damaged.

27. Carefully remove the transmission from the machine.

Avoid causing damage to the transmission or

surrounding parts.

28. Lift the transmission clear of the machine, and lower

it onto suitable supports or secure it to a stand built

especially for transmission or engine service. Secure

the transmission so that it will not move or fall.

29. Remove any external transmission components as

required, including the transmission temperature

switch, and inlet and outlet cooler hose fittings.

Cover all transmission openings.

30. Remove the transmission oil filter (1) and dispose of

properly. Clean the filter mounting surface. Cover or

cap the oil filter mount.

31. If transmission oil is suspect of contamination or

torque converter is damaged, remove the converter

and flex plate from the transmission.

32. Remove the six bolts and washers holding the

converter to the flex plate.

6.6.2

Transmission Inspection and Internal

Repair

The converter is now ready for inspection and/or further

service.

If replacing the entire transmission, transfer the

transmission temperature switch to the replacement

transmission. The gear shift solenoids are included with a

new transmission.

For internal service, refer to the Dana Spicer Transmission

Repair Manual (P/N 31200163).

6.6.3

Transmission Installation

1. Install both the rear transmission mounts on the

transmission. Torque capscrews to120 Nm

(88 lb-ft).

2. Install two guide studs near the top of the bell

housing holes.

3. Use a hoist or overhead crane and sling attached to

the lifting eye at the top of the transmission. Raise

and position the transmission within the chassis.

4. Align the torque converter, align the transmission

bolt holes with the two studs in the bell housing.

Install the eight bolts and washers and torque to

63 Nm (46 lb-ft). Remove the two alignment studs

and install and torque the last two transmission

mounting bolts.

5. Install the two rear transmission mounting bolts on

the frame with two capscrews and two lockwashers.

Apply Loctite

®

242 threadlock to the transmission mount

bolts and torque to 210 Nm (155 lb-ft).

6. Turn the engine over slowly by hand and align each

of the eight flex plate bolts to be accessed. Install

them one at a time. Torque to

35-39 Nm (26-29 lb-ft).

Replace access plug.

7. Remove the hoist or overhead crane and sling.

8. Connect the transmission temperature switch

connector and shift solenoid wiring harness

connectors.

9. Secure the wiring harness to the transmission

housing.

10. Uncap and connect the transmission oil cooler inlet

and outlet hoses at the transmission.

11. Install the hydraulic pump. Refer to Section 8.6.3,

12. Install drive shafts. Refer to Section 5.4.4, “Drive

13. Install air cleaner and tubing.

14. Clean the transmission oil filter mounting surface.

MZ0680

1