4 chain lubrication, 5 boom section separation adjustment, Boom section separation adjustment – JLG 4017 Service Manual User Manual

Page 41

3.17

4017

Boom

e. Removing Extend and Retract Chains

The four extend chains and the three retract chains can

only be removed during a complete boom teardown.

While doing the chain inspection, check all chain clevis

ends for distortion or cracking and sheaves for bearing

wear or grooving from the chain.

If during the inspection, any chain is found to be damaged

or stretched, the chain must be replaced. It is

recommended that when any chain is replaced, that all

the chains and clevis’ be replaced at the same time.

3.4.4

Chain Lubrication

After inspection and before being returned to service,

chains must be lubricated with a quality chain lubricant

(“LUBRIPLATE” Chain & Cable Fluid, “LPS3” or

equivalent).

The lubricant must penetrate the chain joint to prevent

wear. Applying lubricant to the external surfaces will

prevent rust, but the chains should be articulated to

make sure the lubricant penetrates to the working

surfaces between the pins and links.

To prepare the chain for lubrication, the chain plates

should be brushed with a stiff brush or wire brush to

clear the space between the plates so that lubricant can

penetrate to the working surfaces.

Lubricant may be applied with a narrow paint brush or

directly poured on, but the chain should be well flooded

with lubricant and the boom should be extended and

retracted to be sure that the lubricant penetrates to the

working surfaces. All surplus lubricant should be wiped

away from the external surfaces. DO NOT use a solvent

for this wiping operation.

Regular application of lubricant is necessary to make

sure that all working surfaces are adequately lubricated.

In extremely dusty conditions, it may be necessary to

lubricate the chains more often.

Lubrication of chains on vehicles working consistently in

extreme hot or cold conditions requires special

consideration. It is important that a reputable lubrication

specialist, a JLG Distributor or the vehicle distributor be

consulted for guidance.

3.5

BOOM SECTION SEPARATION

ADJUSTMENT

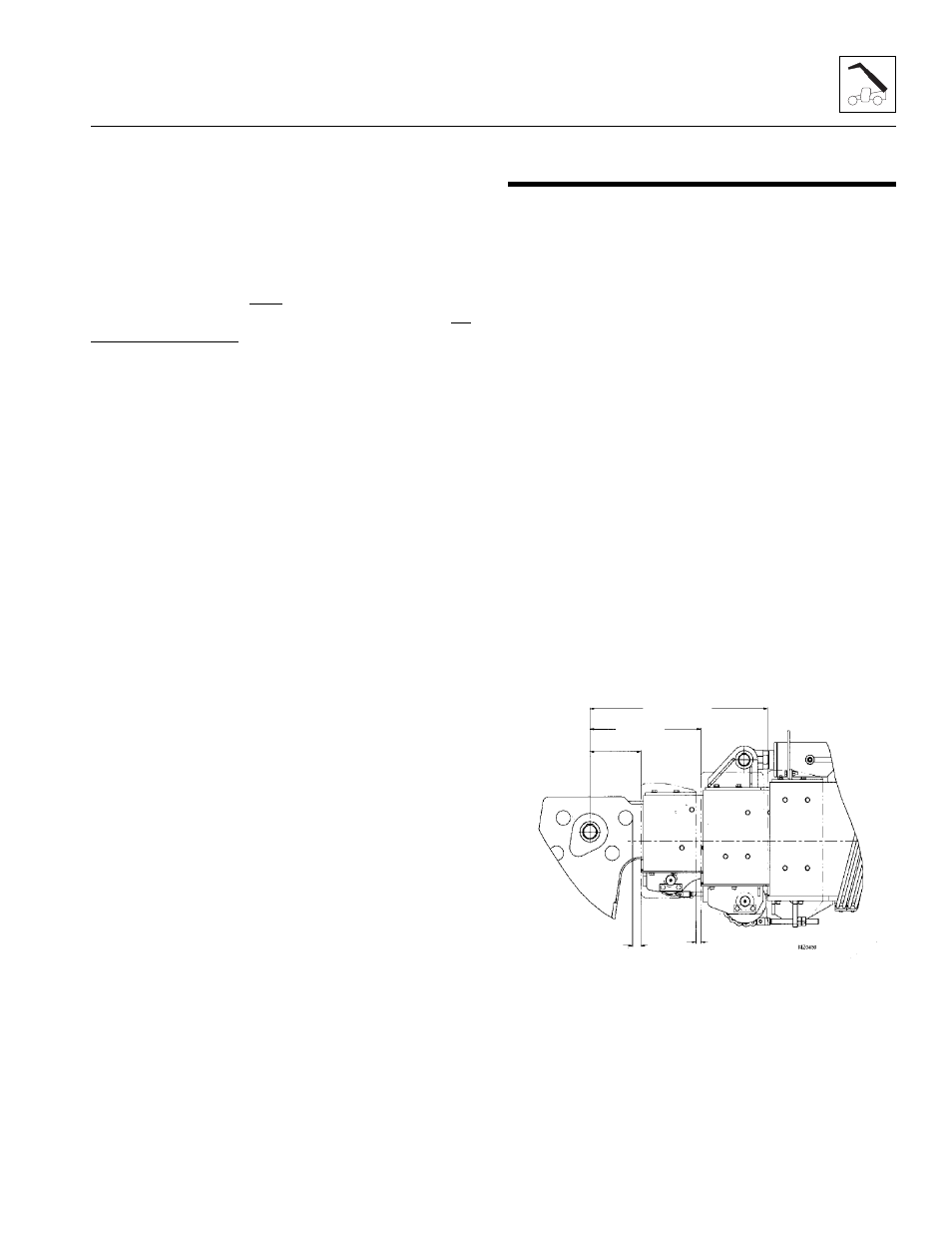

The second, third and fourth boom sections are set to

dimensions between each section. The first and second

boom sections are connected by the extend/retract

cylinder which has no adjustment.

The third and fourth boom sections can be adjusted by

loosening or tightening the extend chains and the retract

chains.

1. Fully retract the boom and raise the boom to a

horizontal position. Place the transmission control

lever in (N) NEUTRAL, engage the park brake

switch.

2. Measure the distance between the boom sections

(1). If adjustments are needed, extend the boom out

0,91 m to 1,2 m (3 ft to 4 ft). Shut off machine.

3. Loosen the locknuts on the extend chains and the

retract chains and adjust as needed.

a. To increase the separation distance: Loosen the

retract chains locknut on the rear of the third or

fourth boom sections one or two turns and

tighten the extend chain locknuts on the first and

second boom sections equally the same number

of turns. A minimum of one full thread on the

clevis must protrude beyond the locknut.

b. To decrease the separation distance: Loosen the

extend chain locknuts at the front of the first or

second boom sections equally one or two turns

and tighten the retract chains locknut the same

number of turns. A minimum of one full thread

on the clevis must protrude beyond the locknut.

797mm

31.378”

499mm

19.645”

229mm

9.016”

37mm

1.45”

20mm

.787”

1