2 safety information, 3 hydraulic pressure diagnosis, Safety information – JLG 4017 Service Manual User Manual

Page 103: Hydraulic pressure diagnosis, Warning

8.3

4017

Hydraulic System

8.2

SAFETY INFORMATION

Petroleum-based hydraulic fluids are used in this

machine. The temperature of hydraulic fluid increases

during the operation of various hydraulic functions. A

heated petroleum-based hydraulic fluid presents a fire

hazard, especially when an ignition source is present.

Accordingly, periodically inspect all hydraulic system

components, hoses, tubes, lines, fittings, etc. Carefully

examine any deterioration and determine whether any

further use of the component would constitute a hazard.

If in doubt, replace the component.

Note: Residual pressure may remain in hydraulic

cylinders, hoses, valve bodies, components, etc. If the

hydraulic lines going to or coming from a component are

taut, slowly and cautiously relieve (“bleed off”) pressure

using the handle provided in the tool kit.

Note: Whenever you disconnect a hydraulic line,

coupler, fitting or other component, slowly and cautiously

loosen the part involved. A hissing sound or slow

seepage of hydraulic fluid may occur in most cases. After

the hissing sound has ceased, continue removing the

part. Any escaping oil should be directed into an

appropriate container. Cap or otherwise block off the part

to prevent further fluid seepage.

Hydraulic system maintenance will, at times, require that

the engine be operated. Always follow safety precautions.

A major cause of hydraulic component failure is

contamination. Keeping the hydraulic fluid as clean as

possible will help avoid downtime and repairs. Sand, grit

and other contaminants can damage the finely machined

surfaces within hydraulic components. If operating in an

exceptionally dirty environment, change filters and

inspect the fluid more often. When servicing the system,

cap or plug hydraulic fittings, hoses and tube assemblies.

Plug all cylinder ports, valves and the hydraulic reservoir,

and pump openings until installation occurs. Protect

threads from contamination and damage.

Some hydraulic functions are actuated by interfacing with

electrical system components (switches, solenoids and

sensors). When the hydraulic system is not functioning

properly, check the electrical aspect of the malfunctioning

circuit also. Refer to Section 9.5, “Electrical System

Schematics,” in this manual.

8.3

HYDRAULIC PRESSURE DIAGNOSIS

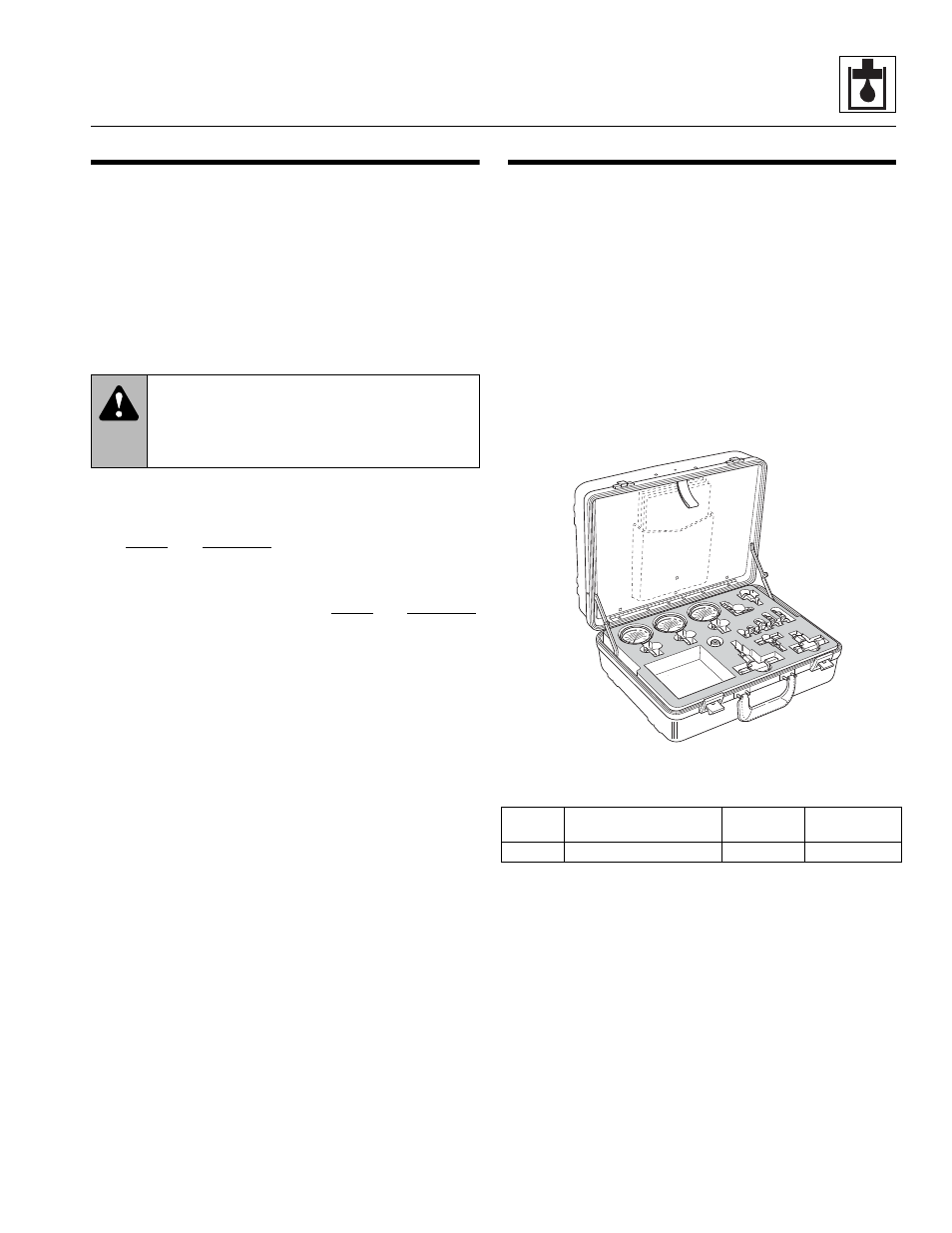

JLG Parts Department has a kit available to use for

hydraulic system maintenance and troubleshooting: the

JLG Pressure Test Kit. The kit is contained in a durable

polyethylene carrying case for demanding field service

conditions.

Pressure Test Kit

The hydraulic pressure test kit is used to pressure test the

various hydraulic components in the hydraulic system.

The kit includes:

• Gauges for testing high and low pressure circuits

• Fittings, couplers and hoses

Contact your JLG Parts Department for ordering

information.

WARNING:

Relieve hydraulic pressure

before servicing any hydraulic component.

Escaping hydraulic fluid under pressure can

penetrate the skin causing death or serious injury.

Part

Number

Description

Approximate

Weight

Price and

Availability

80904003 Hydraulic Pressure Test Kit

10 lbs.

Consult Factory

MZ1460