Mounting-controller, Wiring, Mounting-controller -58 wiring -58 – JLG 601S ANSI Service Manual User Manual

Page 98

SECTION 3 - CHASSIS & TURNTABLE

3-58

– JLG Lift –

3120746

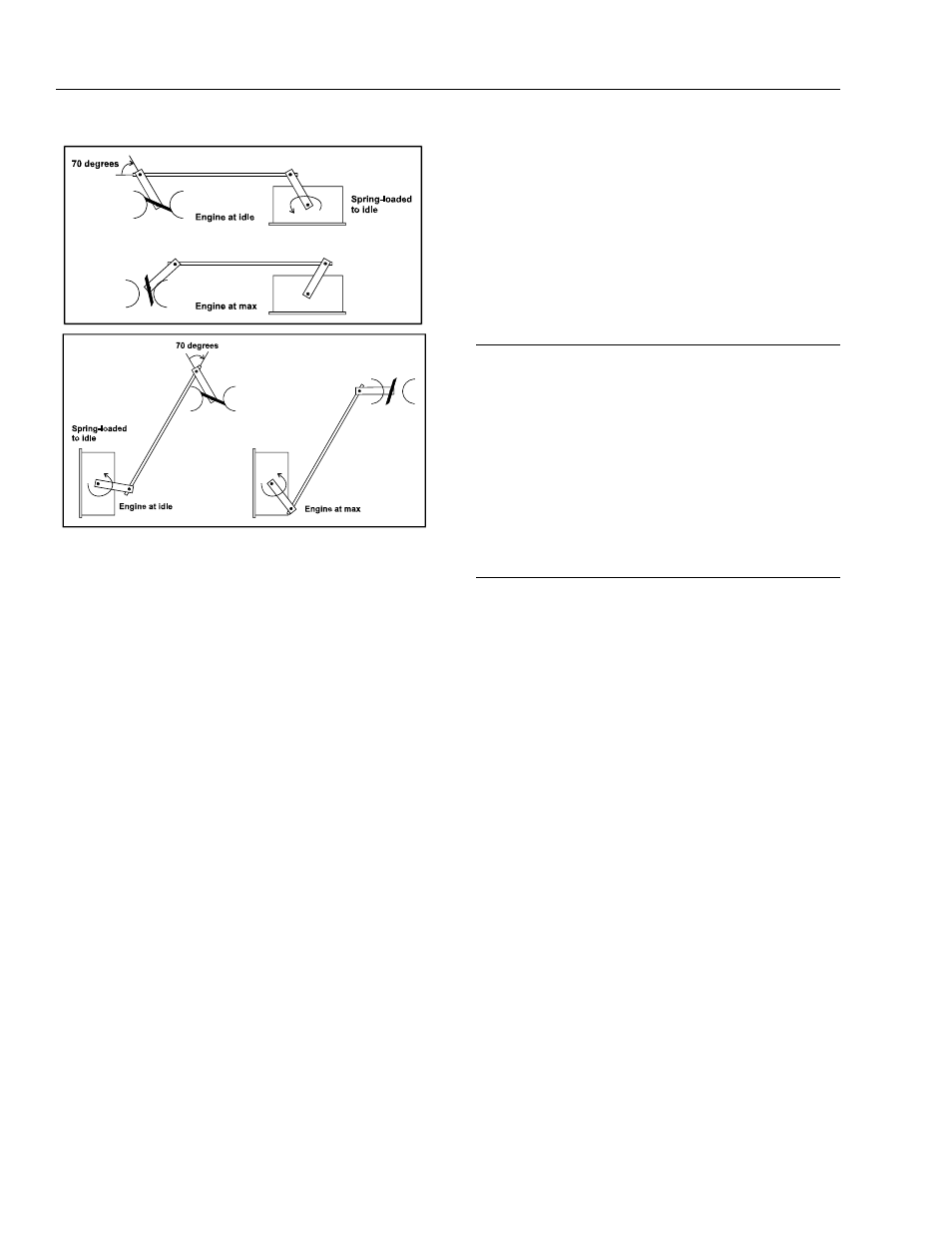

with good linkages. Remember, the Actuator can be

turned 180 degrees on its mounting to “reverse” the

spring-loaded direction. Also, the Actuator can be

mounted in any attitude.

The needed travel of the carburetor determines how far

out on the Actuator arm the rod is to be attached. In most

cases, the carburetor should be moved from closed to

above 10 degrees from full open as the Actuator is moved

min. to max. THEN ALTER THE LENGTH OF THE ROD

SLIGHTLY (PERHAPS 0.030"), SO THAT THE ACTUATOR

IS JUST OFF ITS INTERNAL STOP, AND IS PULLING THE

BUTTERFLY AGAINST ITS STOP. This insures that the car-

buretor can fully close to idle on load dumps, minimizing

overspeeds.

Examine the system for springs, such as carburetor return

springs. These should be removed. Some automotive car-

buretors (as opposed to industrial carburetors) contain

internal springs for accelerator pumps, ect. These may

make good governing difficult, or even impossible. For

this, and other reasons, industrial carburetors are much to

be preferred.

Move the linkage slowly through its travel, and look for

any binding or unexplained forces. Correct any before

going further.

Many “governing” problems are really caused by binding

of the butterfly and its shaft in the carburetor. This is

caused by loading due to vacuum under the butterfly and

atmospheric pressure above when the engine is running.

These forces cannot be felt when the engine is not run-

ning. Therefore, start the engine while carefully controlling

the speed by hand, and feel for binding or airload forces.

Needle bearings on the butterfly shaft are available on

many industrial carburetors to deal with this problem. Any

tendency on the butterfly stick must be corrected.

Mounting-Controller

Select a reasonably cool, dry, and vibration free location.

The rear cover will probably need to be removed during

set-up in order to make adjustments for speed setting and

gain. You may wish to defer final installation until this is

done.

After completing these adjustments, replace cover. Mount

so that water cannot pool on this cover. Always mount the

controller with the strain relief down. This will prevent

water from entering thru the cable, also place the vent

hole in the bottom of the controller down.

Wiring

See wiring diagram for details of hook-up.

Use #16 wire minimum.

Keep all wiring to the Governor as short as is practical.

Go directly from the controller ground terminal (B of the 8

pin connector) by dedicated wire, to the battery “minus”

terminal. If this cannot be done, for some reason, go by

dedicated wire to a very good engine ground.

A properly functioning engine electrical system will supply

13.5 - 14.8 VDC when the engine is running. If wiring size

is adequate, with good connections and proper grounds,

you will get this reading between the wires terminals A & B

of the 8 pin connector when the Governor is controlling

engine speed. Verify this.

Improper hook-up can damage electronics. Re-check wir-

ing before applying power.