JLG 601S ANSI Service Manual User Manual

Page 120

SECTION 3 - CHASSIS & TURNTABLE

3-80

– JLG Lift –

3120746

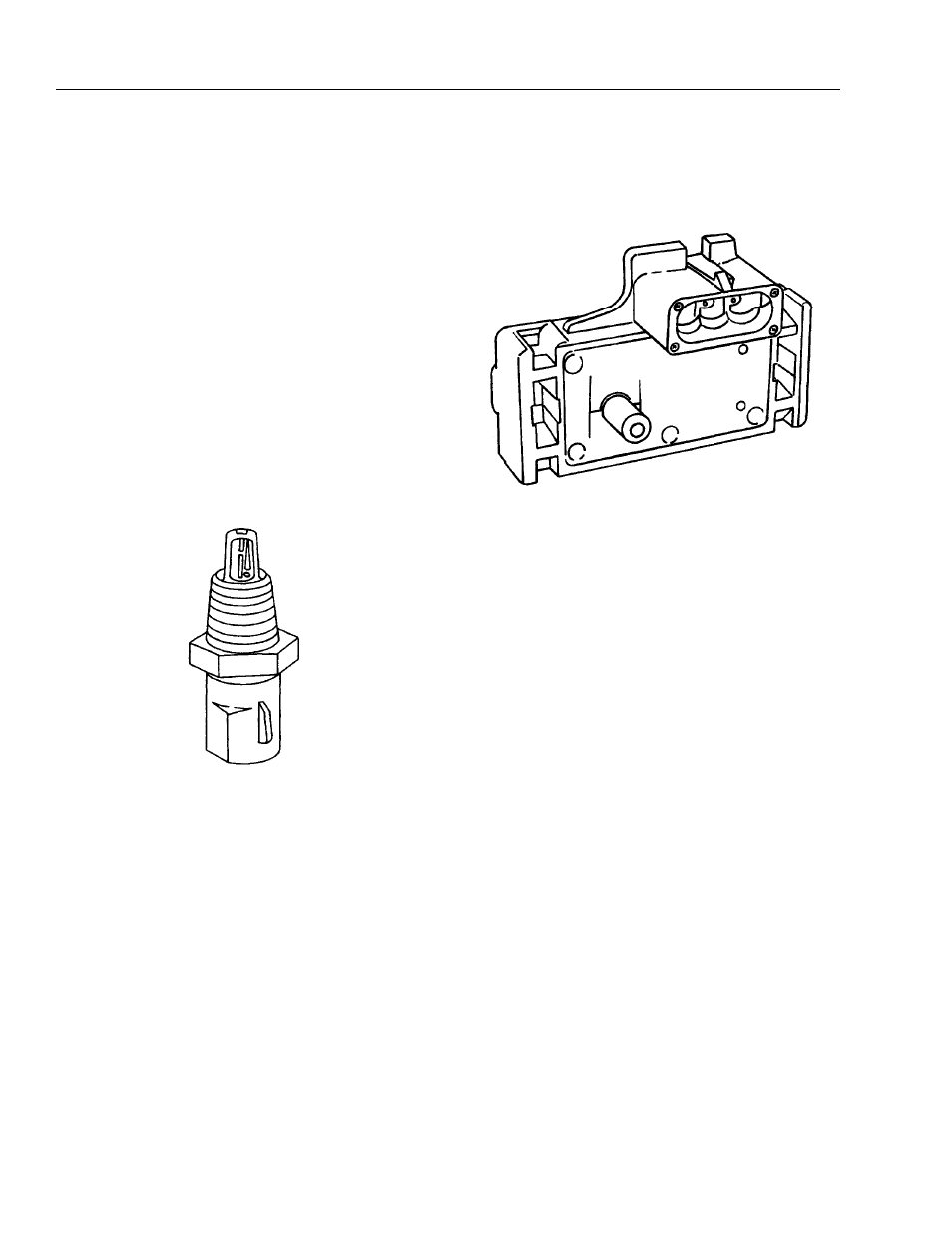

INTAKE AIR TEMPERATURE (IAT) SENSOR

The intake air temperature (IAT) sensor is a thermistor

which changes its resistance based on the temperature of

air entering the engine. Low temperature produces a high

resistance of 100,000 ohms at -40°C (-40°F). High temper-

ature causes a low resistance of 70 ohms at 130°C

(266°F). The Engine Module supplies a 5-volt signal to the

sensor through a resistor in the Engine Module and moni-

tors the signal voltage. The signal voltage will be high

when the incoming air is cold and low when the incoming

air is hot. By measuring the voltage, the Engine Module

calculates the incoming air temperature. The IAT sensor

signal is used to adjust spark timing according to the

incoming air density. An IBM PC-compatible computer with

diagnostic soft-ware can be used to display the tempera-

ture of the air entering the engine. The temperature should

read close to the ambient air temperature when the engine

is cold, and rise as engine compartment temperature

increases. If the engine has not been run for several hours

(overnight), the IAT sensor temperature and engine cool-

ant temperature should read close to each other. A failure

in the IAT sensor circuit will set DTC 35 or DTC 45.

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSOR

The manifold absolute pressure (MAP) sensor responds

to changes in intake manifold pressure (vacuum). The

MAP sensor signal voltage to the Engine Module varies

from below 2 volts at idle (high vacuum) to above 4 volts

with the ignition ON, engine not running or at wide-open

throttle (low vacuum).

The MAP sensor is used to determine the following:

• Engine vacuum level for engine control purposes.

• Barometric pressure (BARO)

If the Engine Module detects a voltage that is significantly

lower than the estimated MAP value for 2 or more consec-

utive seconds, DTC 14 will be set. A signal voltage signifi-

cantly higher than the estimated MAP value for 2 or more

consecutive seconds will set DTC 24.

ENGINE CONTROL MODULE (ECM)/ENGINE

PERFORMANCE MODULE (EPM)

The engine will be controlled by one of two different

Engine Modules. The Ford EFI engine was originally

equipped with an ECM. The EPM was developed to

replace the ECM and provide enhanced performance and

durability. To see the physical difference between the ECM

and EPM, refer to Figure 3-47., ECM/EPM Identification.

The Engine Module controls the following:

• Fuel metering system

• Ignition timing

• On-board diagnostics for engine functions

The Engine Module constantly observes the information

from various sensors. The Engine Module controls the

systems that affect engine performance. The Engine Mod-

ule performs the diagnostic function of the system. It can

recognize operational problems, alert the operator

through the Malfunction Indicator Lamp (MIL), and store

diagnostic trouble codes (DTCs). DTCs identify the prob-

lem areas to aid the technician in making repairs.

The Engine Module supplies either 5 or 12 volts to power

various sensors or switches. The power is supplied

through resistances in the Engine Module which are so

low in value that a test light will not light when connected

to the circuit. In some cases, even an ordinary shop volt-

meter will not give an accurate reading because its resis-

tance is too low. Therefore, a digital voltmeter with at least

10 meg ohms input impedance is required to ensure

accurate voltage readings. The Engine Module controls

output circuits such as the fuel injectors, electronic gover-

nor, etc., by control ling the ground or the power feed cir-

cuit through transistors or other solid state devices.