Inspection, Inspection -6, Disassembly wire rope routing procedure -6 – JLG 601S ANSI Service Manual User Manual

Page 134: Dimension of sheaves when new -6

SECTION 4 - BOOM & PLATFORM

4-6

– JLG Lift –

3120746

12. Remove hardware which secures the sheave guards

and sheave assemblies to mid boom section,

remove sheave assemblies from mid boom section.

13. Remove hardware which secures the wear pads to

the front of mid boom section; remove wear pads

from the top, sides and bottom of the mid boom sec-

tion.

14. Using an overhead crane or suitable lifting device,

remove fly boom section from mid section. Note:

When removing fly boom section from mid boom

section, retract wire rope must be dragged along

with fly boom section.

15. Remove hardware which secures the wear pads to

the aft end of fly boom section; remove wear pads

from the top, sides and bottom of the fly boom sec-

tion.

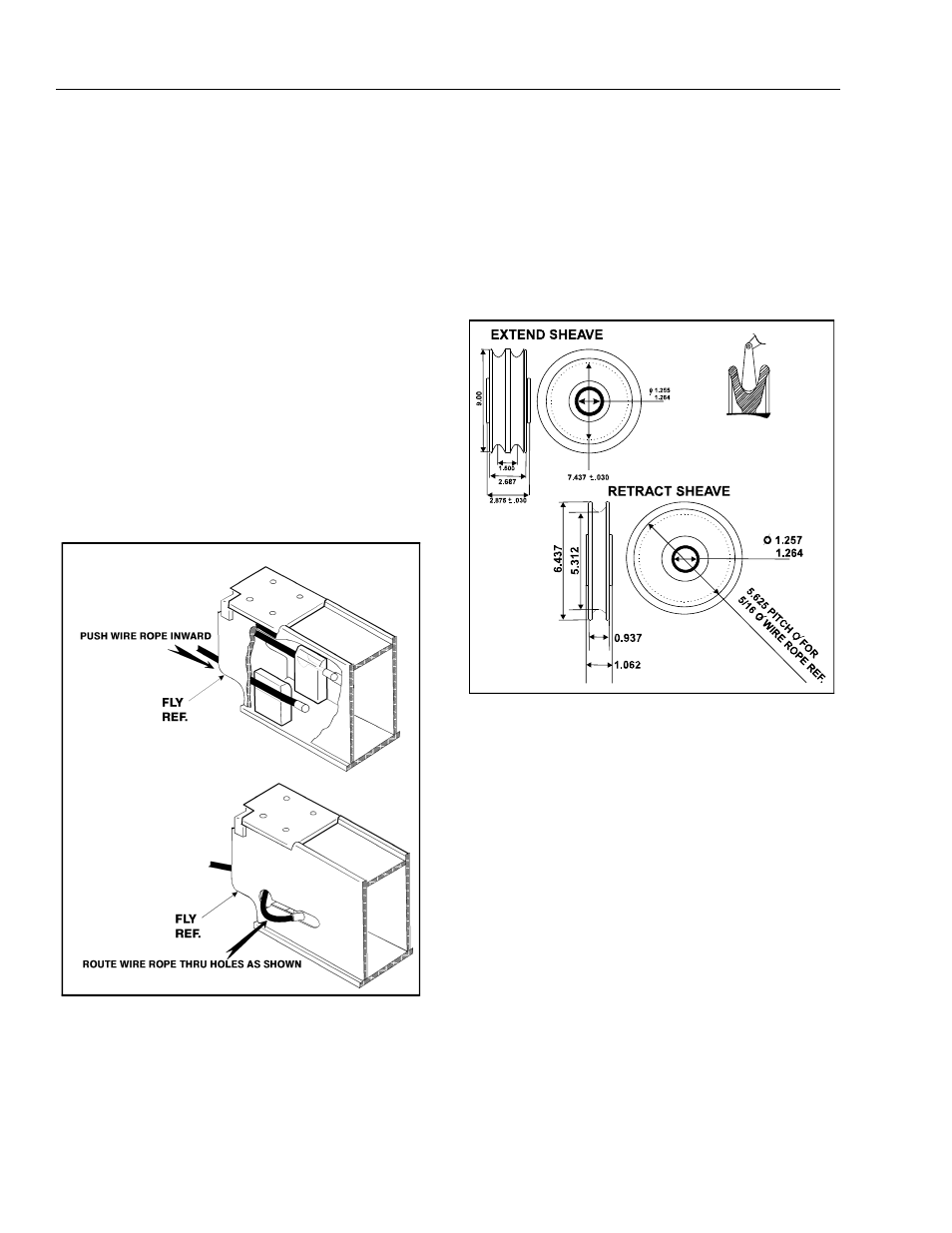

16. When removing wire rope from fly boom section,

push the cable into fly boom. Route wire rope back

through holes in the side of the fly boom section.

Inspection

NOTE: When inspecting pins and bearings Ref. to para-

graph 2-39. Pins and Gar-Max Bearing Repair

Guidelines.

1. Inspect all sheaves (extend and retract wire ropes

and telescope cylinder) for excessive groove wear,

burrs or other damage. Replace sheaves as neces-

sary.

2. Inspect extend and retract wire rope sheave bear-

ings for wear, scoring, or other damage, and for

ovality.

3. Inspect extend wire rope and retract wire rope

sheave pins for scoring, tapering and ovality.

Replace pins as necessary.

4. Inspect telescope cylinder sheave pin for scoring,

tapering and ovality. Replace pins as necessary.

5. Inspect boom pivot pin for wear, scoring, tapering

and ovality, or other damage. Replace pins as nec-

essary.

6. Inspect telescope cylinder attach point for scoring,

tapering and ovality. Replace pins as necessary.

Figure 4-7. Disassembly Wire Rope Routing Pro-

cedure

Figure 4-8. Dimension of Sheaves When New