JLG 601S ANSI Service Manual User Manual

Page 43

SECTION 3 - CHASSIS & TURNTABLE

3120746

– JLG Lift –

3-3

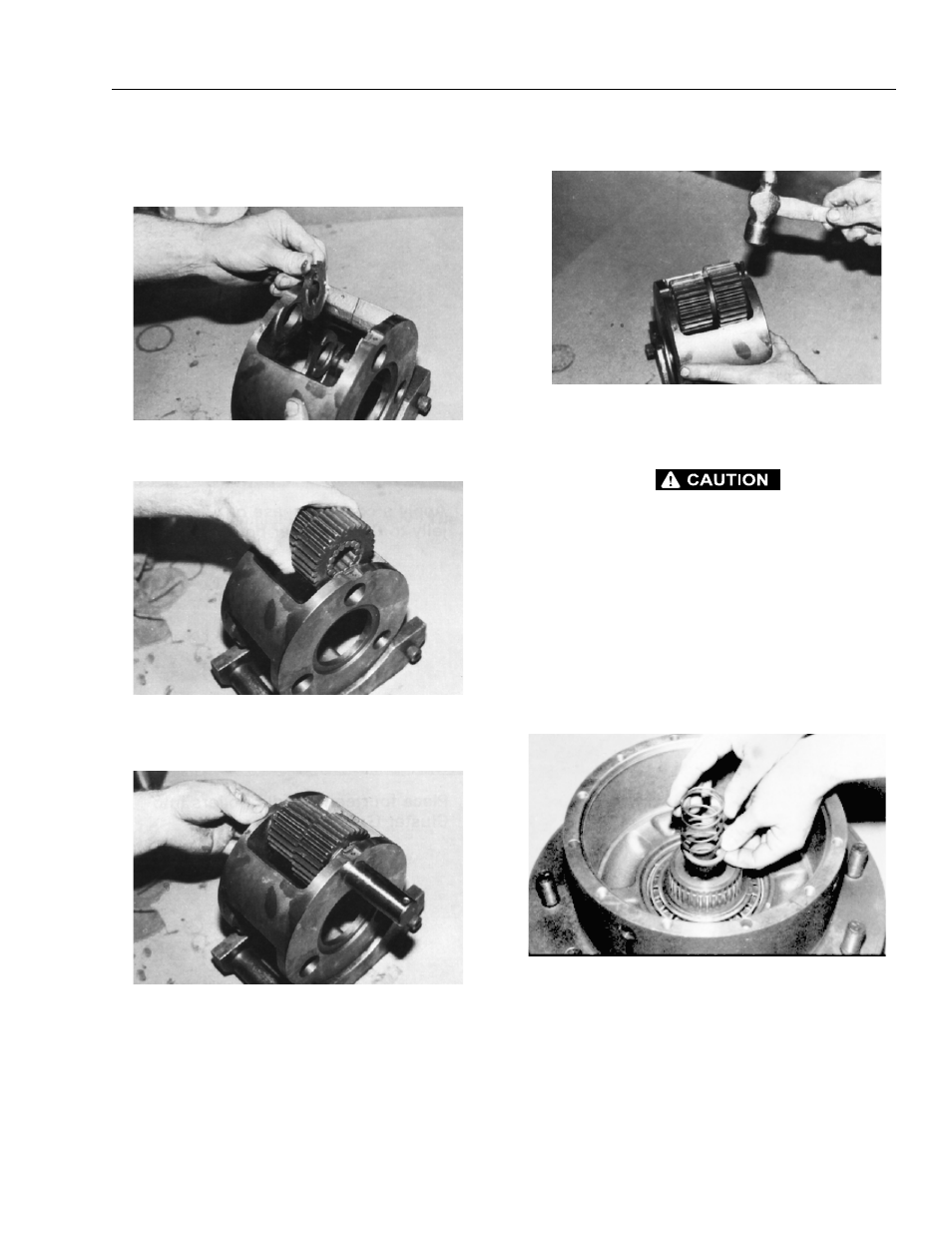

l. Apply grease or petroleum jelly to tang side of

two thrust washers. Place thrust washers against

bosses in carrier with washer tang fitting into slot

in carrier outside diameter.

m. While keeping thrust washers in place, slide

cluster gear into carrier with larger gear on side

with small pin hole.

n. Line up cluster gear and thrust washers with

hole in carrier and slide planet shaft through.

Ensure chamfered side of hole in planet shaft is

lined up with pin hole in carrier.

o. Drive anti-roll pin flush into carrier hole, locking

planet shaft into place.

p. repeat steps (h) through (o) for remaining two

cluster gears.

3. Input Shaft Assembly.

EYE PROTECTION SHOULD BE WORN DURING RETAINING RING

REMOVAL AND INSTALLATION

a. Carefully remove retaining ring (33) from coun-

terbore in the spindle (1) and discard retaining

ring.

b. Remove two spacers (31) and spring (32) from

input shaft.

c. Clean and inspect all parts in accordance with

Cleaning and Inspection procedures. Replace

parts as necessary.

d. Place washer (31), spring (32), and washer (31),

in that order, onto input shaft.